Airline travel is poised to become faster

Numerous supersonic concepts were announced at the National Business Aviation Assn. (NBAA) annual meeting in Orlando in October, indicating it is a technology to watch.

Share

The National Business Aviation Assn. (NBAA) held its annual meeting in Orlando at the Orange County Convention Center and the Orlando Executive Airport a couple of weeks ago. The event, which attracted more than 23,000 people from business, government, manufacturing, corporate aviation departments and MRO, generated considerable news, including an update on Reno, Nevada-based Aerion Supersonic. Aerion CEO Tom Vice announced at NBAA on October 15 that the company, working in close collaboration with Lockheed Martin and GE Aviation, has concluded the conceptual design phase for the AS2 supersonic business jet and has now embarked on preliminary design—a phase that will conclude in June 2020: “We’re on track to fly in 2023, and before that year is out cross the Atlantic at supersonic speed, which will be the first supersonic crossing since the Concorde’s retirement 20 years earlier.”

Vice went on to say “Aerion and our AS2 industry team, comprised of Lockheed Martin, GE Aviation, and Honeywell, have solved many of the tremendous challenges in creating a supersonic renaissance. We’ve overcome some huge technical hurdles and we’re confident we’ll meet Stage 5 takeoff and landing noise requirements [a new noise standard more stringent than current requirements]. We’ve made strides in structures and systems. We’re recruiting top tier suppliers. And we’re attracting the best and brightest engineering talent to the program as we grow our organization.”

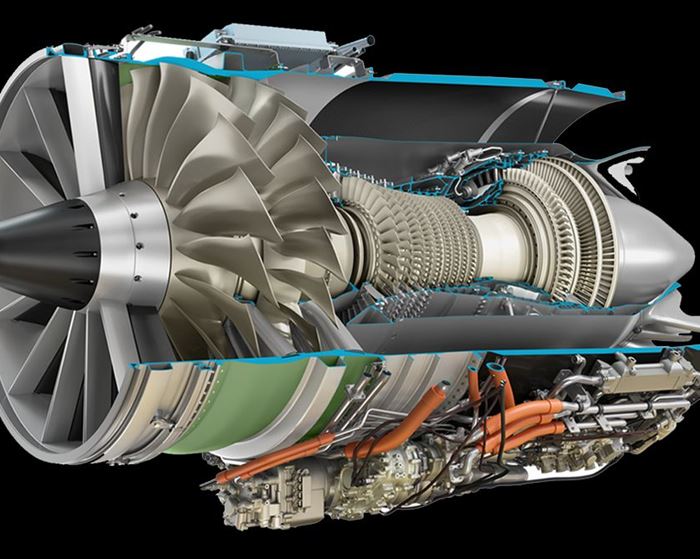

At a joint press conference on the same day with Aerion, GE Aviation announced that it has completed the initial design of the AffinityTM turbofan, the first supersonic engine purpose-built for business jets. GE says the new engine class is optimized for supersonic flight and will be timed to meet the Aerion AS2 launch date. According to the company, the Affinity is a new class of medium bypass ratio engines that integrates a unique blend of proven military supersonic experience, commercial reliability and the most advanced business jet engine technologies. CW has reported previously on the Aerion, and the company says virtually all the airframe will be constructed of carbon fiber composites, with titanium used for leading edges and some internal structures (here’s a link: https://www.compositesworld.com/news/aerion-sheds-light-on-supersonic-business-jet ).

Aerion’s history goes back to 1999, when a predecessor company, ASSET Group (Affordable Supersonic Executive Transport), led by supersonic design expert Dr. Richard R. Tracy, began work on supersonic natural laminar flow (SNLF) wings. In 1999 and 2000, ASSET performed supersonic test flights in collaboration with NASA’s Armstrong Flight Research Center (formerly NASA’s Dryden Flight Research Center) confirming predicted levels of SNLF. That work led an investor group headed by Robert M. Bass to acquire ASSET and its team in 2003 with the aim of commercializing the company’s supersonic technology.

Aerion is only one of a number of high-speed aircraft projects, due to a resurgence in demand for Concorde-like, faster-than-sound planes and shorter flight times. Boom Technology is a supersonic startup that is working on a larger 55-seat commercial craft; its smaller-scale demonstrator is almost ready to fly (here’s the link to CW’s 2017 story on Boom: https://www.compositesworld.com/articles/supersonic-flight-goes-commercial-again ). NASA is involved in a supersonic project with Lockheed Martin, with the goal of reducing or eliminating sonic booms. Now under construction at LM’s Skunk Works plant in Palmdale, California, the X-59 QueSST is designed so that when flying supersonic, people on the ground will hear nothing more than a sonic thump – if anything at all. NASA says that once fully tested and pronounced safe to fly within the US national airspace, the X-59 in late 2022 will begin making supersonic flights over select communities to measure residents’ reactions to any noise they might hear. And, Boeing is looking ahead to the company’s first passenger-carrying hypersonic concept that was debuted at the American Institute of Aeronautics and Astronautics (AIAA) conference in Atlanta in June. Boeing says engineers are working companywide to develop enabling technology will position the company for the time when customers and markets are ready to reap the benefits of hypersonic flight. Kevin Bowcutt, senior technical fellow and chief scientist of hypersonics, say “Boeing is building upon a foundation of six decades of work designing, developing and flying experimental hypersonic vehicles, which makes us the right company to lead the effort in bringing this technology to market in the future.” A hypersonic plane might fly in 20 to 30 years from now, adds Bowcutt.

So it will be interesting to watch these supersonic concepts develop, and which composite or multi-material solutions make them possible.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)