Ford study assesses composite hybrid structural suspension for commercial vehicles

Along with partners Gestamp UK, the National Composites Centre and the University of Nottingham, the project goal is to translate findings into commercial production.

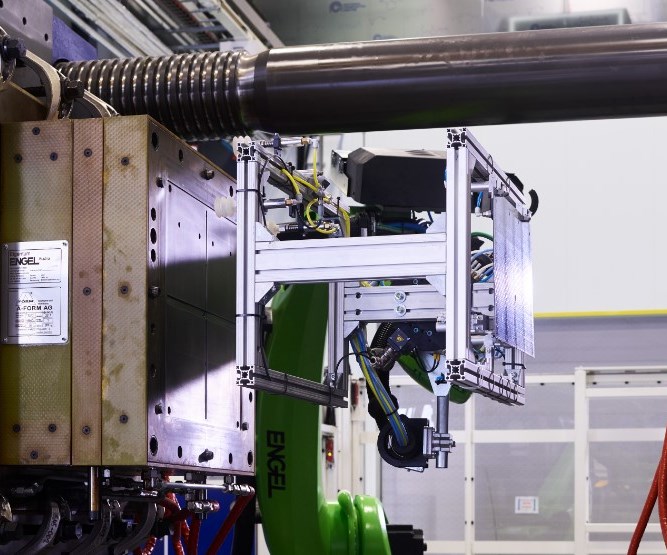

According to Ford, the CHASSIS project is reviewing a variety of manufacturing methods for composite hybrid automotive components, including compression molding. Source | Ford

Ford Motor Co. (Dunton, U.K.) is conducting research and development to quantify the weight savings, CO2 reduction and performance benefits of hybrid structural composite suspension elements for commercial vehicle applications.

Called Composite Hybrid Automotive Suspension System Innovative Structure (CHASSIS), the project is being undertaken by Ford’s Dunton facility, Gestamp UK (Newton Aycliffe, U.K.), the National Composites Centre (Bristol, U.K.) and The University of Nottingham (Nottingham, U.K.), and is designed to assess the feasibility of hybrid components replacing steel predecessors.

Source | Ford

Specifically, the project, which is partially funded by Innovate UK, is investigating composite hybrid structures for suspension crossmembers and lower control arms, as well as solid axles comprising metal, carbon fiber and glass fiber with different matrices to suit loading conditions.

According to Alice Swallow, a Ford engineer working on the project, the innovations of each component are tailored to ensure that each component is able to meet the design requirements of the metallic counterpart.

Manufacturing methods are still under review but could include overmolding, pultrusion and compression molding. Advanced joining techniques will also be utilized to meet volume production cycle times. The hybrid parts will accommodate all clevis requirements for attaching parts to meet current hard point locations, and comply with Ford Motor Co. noise, vibration and handling (NVH) requirements.

The ultimate goal of the project is said to be the development of components and processes for full production, at a rate of approximately 500,000 vehicles per year globally.

Source | Ford

Alan Banks, commercial vehicle supervisor at Ford, who is one of the report’s authors and the project leader, says the CHASSIS project is facilitated by the consortium’s expertise in finite element analysis (FEA) optimization, materials, manufacturing techniques and commercial vehicle requirements, which have accelerated development. This combination of experience helped to identify the correct material and manufacturing method for each component to be able to reduce the weight by an average of 40%, he says.

Gareth Bone, innovation project manager from Gestamp UK, agrees; he says that without the knowledge transfer from other Innovate UK projects that they have been a partner on, such as CLASS, LIGHTJOIN and ARCH, the material selection and early concept development would have required a much longer time period.

The project will also demonstrate the value of the NCC’s investment in latest generation of high volume composite manufacturing process, including injection overmolding, adds Ben Cross, project lead for the NCC.

The report authors include:

- Alan Banks, supervisor, Ford Commercial Vehicle Suspension;

- Alice Swallow, engineer, Ford Commercial Vehicle Suspension;

- Graham Rowland, engineer, Ford Commercial Vehicle Suspension;

- Gareth Bone, manager, Gestamp UK; and

- Ben Cross, technical project lead, National Composites Centre.

For more information, please contact Alan Banks at abanks2@ford.com.

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)