This methodology allows composite simulation data to closely parallel the data necessary to physically manufacture composite products. Generally, this is an advantage over purely mathematical analysis methods like zone-based modeling because the specifics of a given composite product must be taken into consideration during the design phase, and ultimately the results of any final simulation or optimization will require fully defined manufacturing data. Additionally, there are significant benefits to maintaining macroscopic composite models defined at a material “scale 2”, or the scale of the homogenized tow and matrix materials for a single tow layer, but it can be challenging to manage the details of a composite product at this scale.

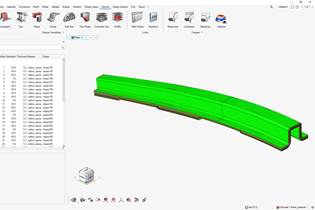

New “Ply Slices” technology in HyperWorks is the corollary to general ply-based modeling techniques. This functionality strives to further link composite simulation with manufacturing by allowing the stress analysist to choose from a selection of specific composite products. The analyst can interact with these products at scales typical of the given product and which are frequently at scales more homogenized than scale 2, while ply slices technology maintains a simulation model at scale 2 in the background. Several specific examples including uni-directional, woven and filament wound products using this new technology will be presented.