Demonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

Share

Toray Advanced Composites (TAC) Cetex thin-ply thermoplastic UD tapes form one focus of its LH2 tank research, offering interesting properties at very low temperatures for semicrystalline polymers. Photo Credit: Toray Advanced Composites

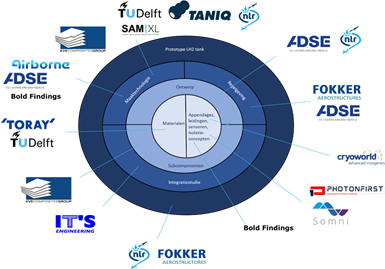

Toray Advanced Composites (TAC, Nijverdal, Netherlands) announced the Netherlands (NL) LH2 composite tank consortium in December 2021. The 45-month project is funded by the Netherlands RDM (research & development mobility) Fund to develop a long-life, fully composite LH2 tank for civil aviation. “The goal is to enable zero-emissions aircraft,” explains Marlie Koekenberg, director of commercial aerospace programs for TAC. “We believe the light weight that composites achieve will provide better storage options for both gaseous and liquid hydrogen as well as cost savings, but the concepts for aircraft applications need development. For single-aisle commercial aircraft, the energy density of compressed hydrogen gas is not sufficient to provide the necessary range; this can only be reached with liquid hydrogen, stored at 20 Kelvin/-253°C.”

Koekenberg notes that TAC and the Netherlands Aerospace Center (NLR, Marknesse) had already begun initial work on composite LH2 tanks and had discussions with Airbus (Leiden, Netherlands). “We decided to team and write a bid proposal,” she explains, “and were awarded the project financing in October 2021. We started our various work packages as a team in January 2022.”

This team includes 14 partners, all based in the Netherlands, spanning the supply chain. TAC is the project leader, with expertise in both thermoset and thermoplastic composites as a materials supplier. Technical University of Delft (TU Delft) had already been working with NLR to test metal LH2 tanks from partner Cryoworld. Other partners and expertise include:

- GKN Fokker — tank fabrication and testing.

- Bold Findings — plastics processing expertise.

- IT’S Engineering — CAD structural engineering and analysis.

- KVE Composites — thermoplastic composites welding.

- Airborne – robotic composites production and automation.

- PhotonFirst — optical fibers for structural health monitoring (SHM).

- Somni — fiber optic sensors for H2 levels and SHM.

- Aircraft Development and Systems Engineering (ADSE) — engineering, certification and consultancy experience in transportation systems.

- TANIQ — software for optimized design and robotic winding of composite tanks.

- SAM|XL — TU Delft factory of the future for sustainable autonomous manufacturing.

Koekenberg notes that the project is also in alignment with key industry OEMs, including Airbus, Embraer (São José dos Campos, Brazil) and ZeroAvia (Hollister, Calif., U.S. and Kemble, U.K.). “We want to make sure that we understand their operating conditions and needs so that the demonstrators we develop meet aircraft requirements,” she adds. “In fact, that is a key part of the development work we are doing — to fully understand and define the requirements for these composite LH2 tanks.” Other key deliverables from roughly 20 work packages include:

- Material properties of (thin-ply) thermosets and thermoplastics at room temperature and -253°C.

- Manufacturing technologies for vacuum-isolated LH2 tanks including insulation, advanced tooling and welding/bonding techniques for connectors.

- A composite LH2 tank demonstrator, with sensors and an SHM system, demonstrated in static and fatigue testing.

- Inventory of required auxiliary systems and system integration for application in aviation.

- Test facility for testing materials and structures in extremely cold conditions.

- Development of qualification, certification and safety procedures for application in aircraft.

Materials and testing

“We have set up additional facilities for testing composite materials at 20 Kelvin,” says Henri de Vries, senior scientist composites at NLR. “And we are already busy with testing materials to measure if they can resist microcracking and permeation of H2 through the laminate. We have experience from our work on the engine thrust frame for the Ariane 6 launch vehicle, but that was at a higher temperature, closer to 80 Kelvin. And even though we are testing thermosets, this is mostly to establish a benchmark. We focus instead on thermoplastics, which is also the expertise of TAC, because we have seen interesting properties at very low temperatures for semicrystalline polymers such as polyaryletherketones [e.g., PAEK, PEEK, PEKK].” These thermoplastics also offer the potential for welding, notes de Vries. “This could offer an easier assembly method for piping connections compared to traditional sealing of metal fittings to a composite tank.”

This testing will take 18 months, says de Vries. “The first test results already look promising,” he notes. “And we are doing a lot of permeability testing in order to select the best materials.” In Type IV compressed gas hydrogen (CGH2) tanks, the carbon fiber-reinforced epoxy is wound around an unreinforced nylon or high-density polyethylene (HDPE) liner as a permeability barrier. How will this be achieved in the demonstrator composite LH2 tank? “The composite material itself is not that bad,” says de Vries. “We have one already that has survived thermal cycling in liquid helium at -269°C. Further testing is necessary, but it’s hard to do a 20-year life’s worth of testing within a few months.”

“One of the issues,” he continues, “is that as soon as you have microcracks in the surface layer, then you have hydrogen permeation, so the behavior could be from this or from thermal cycling or from both. One thing we do know is that, in general, the more homogeneous your laminate and material structure is, the lower the thermal stress is, which enables better mechanical performance.” This is interesting because one of the deliverables of the project is to test thin-ply materials, made from spread-tow carbon fiber. In theory, these offer homogeneity due to an increased number of thinner layers. “However, there are a lot of factors that play a role,” says de Vries, “including the type of fiber and resin wetout. So, this is part of what we are investigating.”

Demonstrator, inner and outer tank challenges

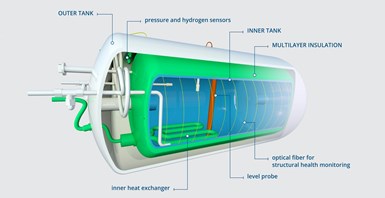

The project will culminate in producing a fully composite demonstrator tank, equipped with sensors and auxiliary systems, which will be tested in thermal and load cycling to assess performance and durability. “We will make a small-scale tank, perhaps 80 liters, which is more affordable for repeated filling with LH2,” says Koekenberg. NLR will design and build the inner and outer tank.

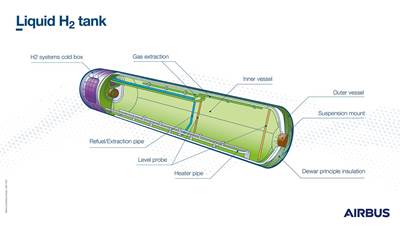

“The outer tank is more of a protective shell,” explains de Vries. “It must withstand the aircraft landing loads and typical FAA-required crash loading, but it will also have to pass the fire and smoke toxicity (FST) requirements for aircraft fuel tanks and equipment. However, it doesn’t have to deal with the very low temperatures and permeation of hydrogen’s small atoms like the inner tank.” Another issue for the inner tanks is the need for baffles to keep the liquid fuel from sloshing, and these must be joined to the tank walls and end domes. This results in a large temperature delta between the part immersed in cryofuel and the part in the inner tank wall in contact with ambient temperature. There are also issues with fuel extraction and boil-off equipment that contact both the inner and outer tanks. “Thus, we have all kinds of thermal expansion issues and then how to connect the inner and outer tanks into one unit,” says de Vries.

“We believe aircraft regulations will require the MLI to also be fire resistant,” says de Vries. “For most cryotanks, this is not the case. So, we may have to apply different materials and that is much more complex. We also need a lifetime of at least 10 years, and then we will have to see how the vacuum between the tanks and insulation performance is maintained.”

Manufacturing methods

De Vries says that GKN Fokker will focus on prepreg tape winding for LH2 tanks, studying industrialization and cost, while NLR is considering automated fiber placement (AFP). “We have discussed winding within NLR,” he says, “but we think it will be easier for us to produce a more homogeneous material structure using AFP. If you have a very good winding facility, then you can come up with something simpler than fiber placement, but process control is key.” Will the tank be consolidated in-situ or in a secondary autoclave cycle? “In-situ consolidation is too complicated for this LH2 tank,” says de Vries.

Comparison with metal tanks

Will this project be able to offer a comparison between a composite LH2 tank and metal tanks? “We hope that when we finish, we can indeed compare our demonstrator with similar metal tanks,” says Koekenberg, “which Airbus is developing now.” This work is being done at the Airbus zero emission development centers (ZEDCs) to support its goals of having a ZEROe commercial aircraft in service by 2035, for which it is currently working with CFM International (Cincinnati, Ohio, U.S.) to test a hydrogen combustion engine on an A380 testbed.

“This makes sense,” adds de Vries, “because they need to learn more about system layout and establish a baseline with the EASA as the regulatory authority regarding what the safety requirements will be. And the metal tanks, being more mature, will be very suitable for that. What we are looking at is longer-term.”

“Our collaboration is contributing to the acceleration of hydrogen technology in commercial aerospace,” says Koekenberg. “Our consortium is representing a crucial part of the supply chain to make this happen. We are very proud to be leading this aerospace revolution, in full alignment and shoulder to shoulder with the major aircraft and engine manufacturers.”

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRead Next

CFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreWill the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.png;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)