Measuring energy use to enable sustainable composites production

Airbus subsidiary CTC uses new technology to measure energy use in machine components and processes to optimize equipment, production lines and guide decisions for future composites.

Share

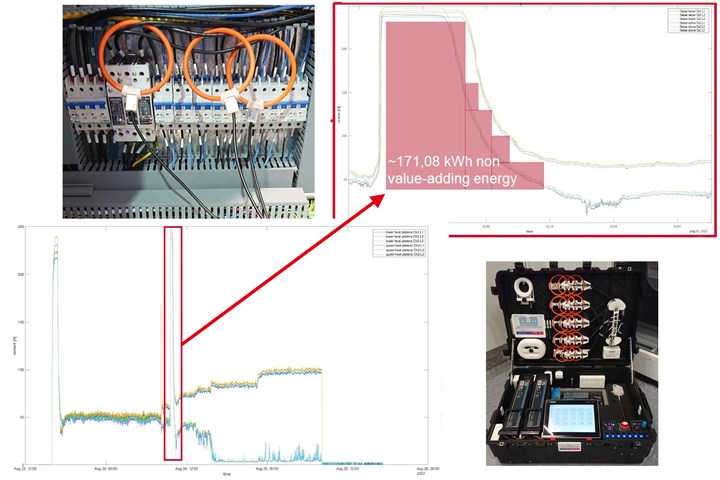

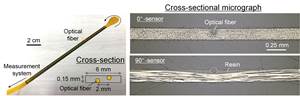

Optimizing an RTM process. The Rogowski coils (orange loops) in CTC’s portable energy recording unit (PERU, lower right) measure electrical current during resin transfer molding (RTM), enabling analysis to reduce energy use. Source (All Images) | CTC, Airbus

Transition to net-zero emissions by 2050 is key for decarbonization. To achieve this, more energy-efficient solutions for buildings, transportation and industry must be developed and scaled rapidly. Most manufacturers are well aware that improving energy efficiency reduces cost and often improves emissions. But all industries, including composites, now face a new urgency. Composites producers have noted that customers are demanding life cycle analysis/assessment (LCA) reports, where energy use is a key metric. And engineering teams are being asked to choose materials and processes that will help their companies meet emissions and sustainability goals. Thus, the ability to measure and understand energy use during composites production is becoming increasingly important.

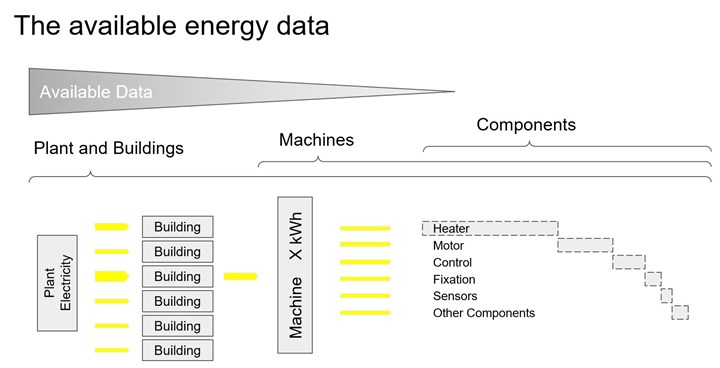

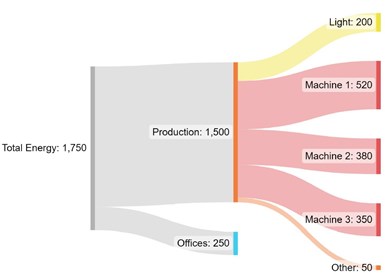

Aircraft production has been able to measure energy use per building, but now, using CTC’s technology, it can also be measured for machines and their components, enabling analyses like this sankey diagram for energy use. Source | CTC, Airbus

The Composite Technology Center, CTC GmbH (Stade, Germany), a 100% Airbus subsidiary, has developed such a solution. A modular, portable system that enables better measurement and analysis of energy use across machines and production lines, this technology supports simultaneous recording from a machine or system as well as its components, such as individual motors or heating elements. As a result, it can help identify potential energy savings and optimized operations. For example, is it better to turn a machine off and on or to let it run in standby mode?

The technology has already been used to evaluate automated fiber placement (AFP) machines and presses, as well as autoclave, resin transfer molding (RTM) and thermoplastic composite molding processes. It is being used by Airbus to improve machine control systems and tooling approaches, but also to guide materials, process and equipment decisions for future airframes.

Developing the portable energy recording unit (PERU)

Formed in 2001, CTC is located between the Airbus vertical tail plane (VTP) factory and the Composites United/German Aerospace Center (DLR)/Fraunhofer IFAM facility known as CFK Valley Nord. It is thus perfectly situated between composites-intensive serial production and R&D. Its development of energy measurement technology started with a request from colleagues at the VTP plant, explains Jan Manuel Ohm, project leader at CTC. “They knew how much energy they were consuming at a building level, but not what was driving that consumption at a machine level. Most of the machines were acquired before energy measurement became so relevant and didn’t have adequate measuring capability built in. We needed a system that could measure the power use in the machines, but also something that was easy to use — not just the hardware but also the data collection.”

Ohm and his teammates, Florian Kohne and Jannis Eckhoff, researched what was state-of-the-art and available in measuring systems. “The devices we found could only use limited amounts and types of sensors,” says Ohm. “If you have multi-current power — which is common with big systems — you would be able to see that machine’s energy use on an overall level but not what is happening within its components.” The team decided this wasn’t sufficient, and Kohne was tasked to develop a new concept.

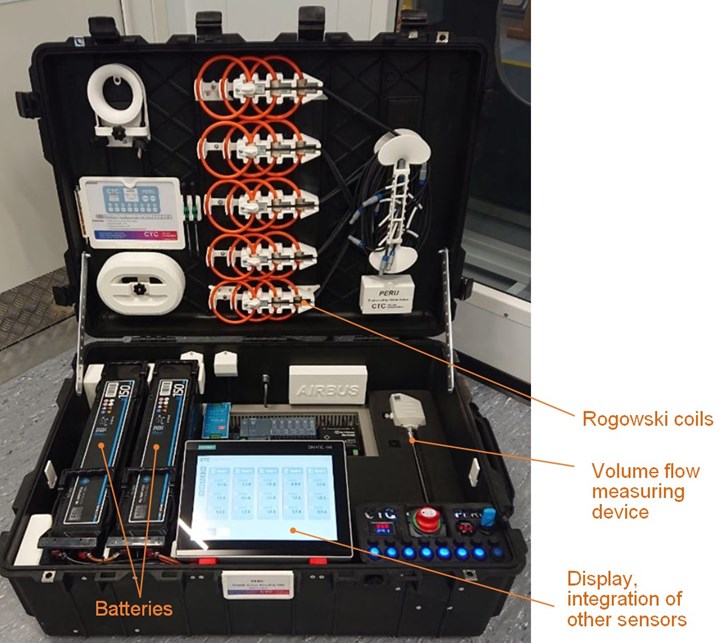

The result is the portable energy recording unit (PERU), which looks like a hot bonder but is larger, roughly 1 × 1.5 meters (Fig. 1). At its heart is a programmable logic controller (PLC), which enables connection to a wide range of sensors and inputs.

Figure 1. Portable energy recording unit (PERU). Measuring 1 × 1.5 meters, PERU can measure electrical use of up to five machines or machine components simultaneously, can run for 5 days on its batteries and can integrate a wide range of other sensors along with its volume flow measuring device that assesses the flow of air, water or heat.

The multiple orange rings on the upper half of the unit are Rogowski coils, a type of compact and economical transducer for measuring electrical current. The coils on the PERU enable measuring the electrical energy use of up to five components simultaneously.

On the bottom half of the unit are batteries that enable the unit to be operated without wired power. “We’ve been able to leave the system running for 5 days without recharging,” says Ohm. There is also a measurement display where multiple other sensors and measuring devices can be integrated and controlled including a volume flow measuring device.

“This allows us to measure the flow of air in vacuum and pressurized applications as well as water or heat flows,” Ohm explains. “The gaseous flows are measured with a thermal mass flow meter and because we are using a PLC, almost any sensor can be integrated, so we are very flexible in what we can measure, depending on the customer’s requirements.”

Analysis and optimization

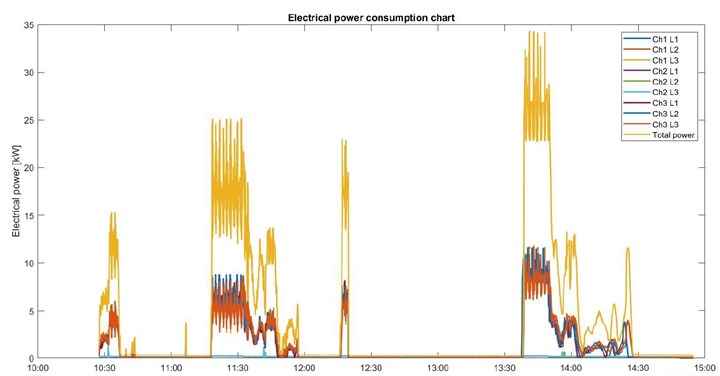

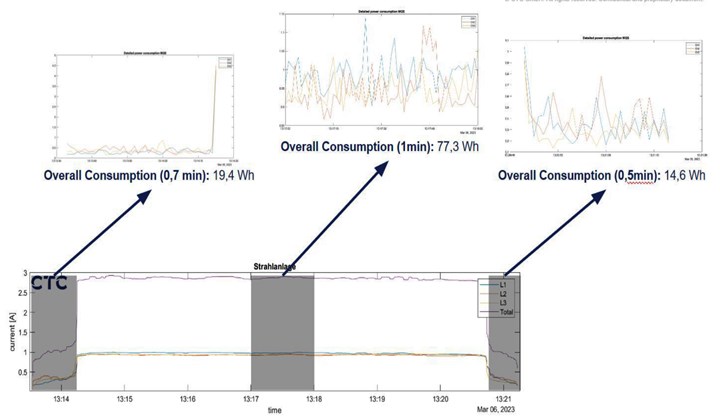

A simple app was developed using Matlab software (MathWorks, Natick, Mass., U.S.) that gives a quick plot as a starting point (Fig. 2). “For this, we plot two channels: electrical current and time,” explains Eckhoff.

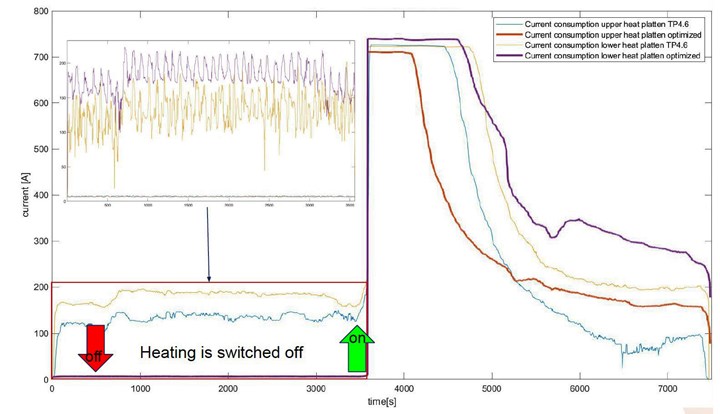

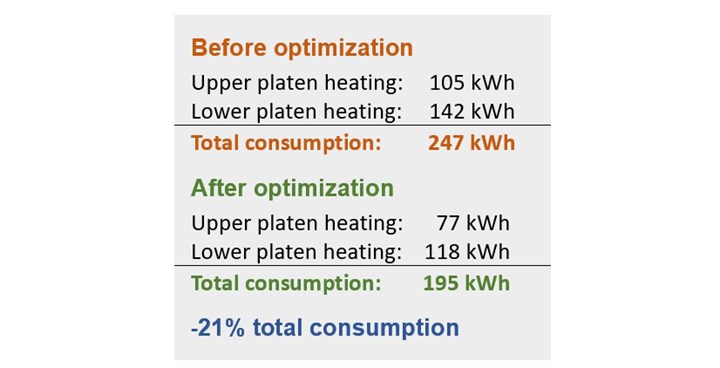

Figure 2. Analyses and optimization. A simple Matlab app gives a quick plot of two channels (top), but more detailed analyses are possible including a plot of different components within the same machine (center) and the optimization of upper and lower platens in a heated press for an RTM process (bottom), which achieved a 21% reduction in overall electrical energy consumption.

“We can also do detailed analysis, where we can show interactions between different components in the machine. We can calculate the overall machine energy consumption, and then zoom in and analyze how this is comprised from different components. For example, we identified a machine in which the cooling and heating components worked against each other in a non-constructive way, resulting in unnecessary energy consumption.”

He notes there are also other effects. “When we couple our energy data with process data, like pressure, we can provide even further analysis. For example, we can match energy peaks and overall consumption with information from the process and can diagram how the process uses energy and by which machine components.”

“When we couple this again with information from our flow sensors, we can get information about other forms of energy like thermal flows, i.e., heating and cooling,” adds Eckhoff. “Or we can add in displacement sensors and correlate this data with machine movements. Then we can analyze how efficient the machine is and we can optimize the process to increase energy efficiency.”

This data can also be used for other types of analysis. “We can analyze the process, for example, to see energy usage during machine startup, operation and shutdown,” says Eckhoff. “And then we can compare this with standby consumption when the machine is left on without processing [e.g., parasitic draw] and make decisions on when to turn the machine off based on real data, not just assumptions. We can also look at process variations. In a press operation, for example, the heating of the molding tools tends to be much more energy-intensive than the other operation phases. A better option may be to keep the tool at a constant temperature versus letting it cool down and then heating it up again. We can also look into the different components during each of those phases and help optimize the process and equipment operation.”

Energy savings of 20-30%

Ohm notes that his team has been able to identify energy savings from 20-30% for multiple customers using the PERU and this type of data analysis. Eckhoff describes a specific case history as an example. “This is an energy measurement for a large-scale CFRP part,” he explains. “We have a large tool with a lot of mass, and we heat it up to 100°C. And then we take the hot tool out, but the heaters remain on during reloading, which takes over an hour due to the process chain involved. We were able to show our customer measurement data for the current process and also where we turn off the heaters until the tool is fully loaded into the equipment. The latter shows a 30% energy savings. This might seem obvious, but without the data for each component in the machine nothing would have happened. That is why it makes a big difference.”

“Within the same type of machine — AFP systems or large presses, for example — it is possible to assess if models from certain suppliers use more or less energy than others.”

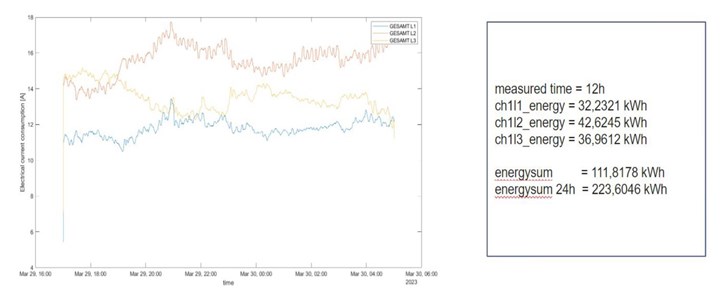

CTC measurement of energy use in different phases of a process (top) and for one machine in standby mode (bottom).

Ohm says the team is analyzing energy consumption in production lines, identifying which machines use more energy. Even further, within the same type of machine — AFP systems or large presses, for example — it is possible to assess if models from certain suppliers use more or less energy than others. “This is not only important for our own assessments and sustainability targets,” says Marc Fette, CEO of CTC, “but it can become a competitive advantage for suppliers. We recently measured the energy flow in various equipment and found that certain models can cost as much as €10,000 per year just to have in standby mode. Nobody has been aware of this kind of data, not even the machine manufacturers.”

“Again, we can then look into each machine’s different components and gain even more understanding of why there is that difference in energy usage,” adds Ohm. “We can identify if components are working together or against each other in different process steps. And we can assess if the control unit has planned the actions of the different components efficiently or not so efficiently. We can then work to improve the control system or how components are operated to achieve energy savings in existing production lines.”

“Certain models can costs as much as €10,000/year to have in standby mode.”

“We can go into any facility,” he continues, “and we can measure any equipment and make the analysis for saving energy and then compare with possible optimizations, other process chains or the same production at other facilities. And we are building more PERU devices, making improvements, so that we have even more possibilities for these analyses.”

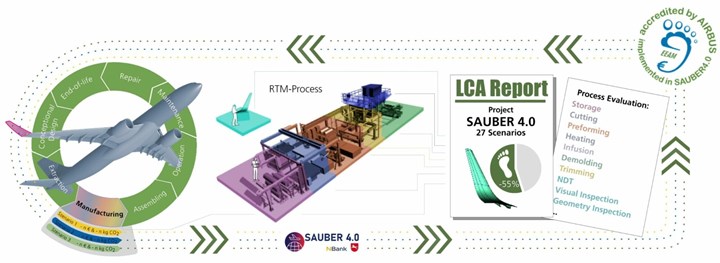

Basis for future airframe optimization

“Everything we have spoken about so far has been to improve existing facilities,” says Eckhoff. “The other part of this technology’s value proposition is providing data for LCA and preparing/specifying future production systems. If we know how our machines are operating today, we can estimate the energy that future production systems will consume and then optimize the energy efficiency of those systems before they are even built.”

“These approaches are technology bricks, which we must have for future aircraft components and production systems,” says Fette. “We have to better specify future sustainable production processes, both within each process chain — including digitally connected machines — as well as overall infrastructure. To do this, we must know what data we need, which sensors have to be in the process chain and also in each machine. So, the results we are creating are the input for the specification of new products, and especially for new production systems for future aircraft.”

“We believe the possible applications for PERU and the analyses it enables are huge,” continues Fette. “There will also be a certain point in time where companies supplying commercial aircraft will have to provide this type of energy use information. So, it’s important that they know what's going on in their production. But even without this pressure from OEMs or regulatory bodies, we see our technology as one part of an approach that is good for business and the planet — they are not opposed. Optimizing energy use is a good example where you can combine economic and ecological benefits to advance composites.”

Related Content

Streamlining aerospace composites operations with RFID tracking

Tier 1 Sekisui Aerospace’s implementation of RFID tracking, sensors and Xemelgo software at two of its production facilities led to increased productivity, eliminating bottlenecks and reducing labor costs.

Read MoreMeasuring ply-wise deformation during consolidation using embedded sensors

Strip-type shape sensor method claims real-time measurement of ply-wise deformation.

Read MoreTechnology Marketing Inc. to distribute VacPuc digital sensors

VacPuc is expanding its range of global distributors to deliver its vacuum pressure measurement solution to the composites market.

Read MoreUD researchers advance TuFF composite's viability for aerospace

The University of Delaware’s research team continues to mature the short fiber composite’s cost competitiveness with metal through sensor embedding, virtual modeling and TuFF thermoset manufacture.

Read MoreRead Next

Composites end markets: Industrial (2024)

The use of composites in industrial applications is increasing, driven by the need for higher performance and longer life, whether its parts for industrial machinery, EOAT components, corrosion-resistant equipment and more.

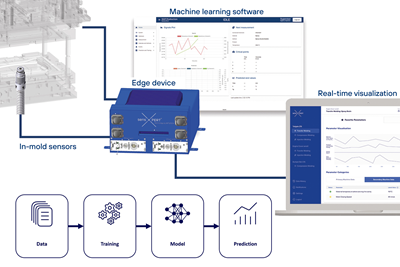

Read MoreNext-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

Read MoreManufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

Read More