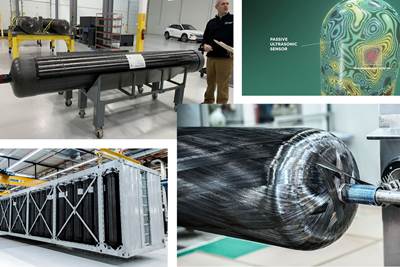

Manufacturing tech for scalable Type V hydrogen tank fabrication, CFRP lifecycle management

Cygnet Texkimp’s Multi Roll Stack and composite recycling technology catalyze ASCEND program’s mission to optimize aerospace, automotive hydrogen storage and CFRP sustainability.

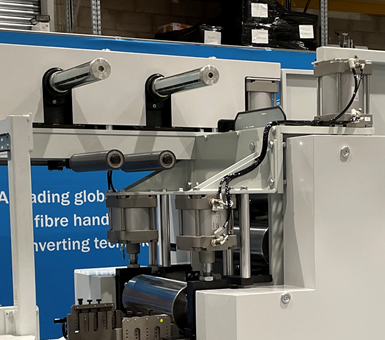

Cygnet Texkimp’s Multi Roll Stack towpreg and prepreg processing line. Photo Credit: Cygnet Texkimp

In the quest to decarbonize the mobility sector, hydrogen stands as a developing cornerstone fuel due to its extreme energy density of 120 megajoules per kilogram. However, this high energy-to-mass ratio is starkly contrasted by its volumetric energy density, a mere 8 megajoules per liter under ambient conditions. Such a paradox necessitates sophisticated storage systems that safely contain hydrogen at pressures of 350 to 1,000 bar or at cryogenic temperatures of -253°C (-423.4°F).

Solutions currently range from Type I all-metal tanks, hindered by weight and capacity constraints, to the more advanced Type III and IV systems, which employ a metallic or polymeric liner respectively, enveloped in carbon fiber-reinforced polymer (CFRP) using epoxy resin. Yet, the future beckons with widespread adoption of Type V tanks — linerless, full CFRP constructions representing a significant leap in weight optimization and volumetric efficiency.

Type V tanks, while revolutionary, face unique challenges. Consider that hydrogen molecules have a kinetic diameter of approximately 2.89 Ångströms, rendering them difficult to contain. Type V tanks must inhibit the permeation of hydrogen through the intricate layers of CFRP laminates. Moreover, their high-pressure conditions contribute to the risk of microcracking and delamination, exacerbated by the absence of a liner to serve as a mechanical buffer.

While Type V tanks are gaining adoption in space vehicles, including launch rockets and lunar landers, they still need to be optimized for hydrogen storage in mobility vehicles. Manufacturing these linerless structures is complex, and current production rates are insufficient for mass adoption, which also leads to higher costs. Therefore, automating and optimizing CFRP filament winding machinery for high-rate Type V tank production to minimize cycle times and material waste is imperative.

Addressing high-rate CFRP manufacturing

The ASCEND (Aerospace and Automotive Supply Chain Enabled Development) consortium was established to enact change in composites-intensive component development for high-volume markets. This cross-sector initiative, partially funded by the U.K. Government, bridges the aerospace and automotive industries to pioneer innovations in lightweight design, material systems, automation, electrification and multifunctional integrated structures. The 3-year program started in 2021 with an ambitious objective: to elevate as many of its research areas as possible to technology readiness level (TRL) 6. This involves demonstrating key rate targets at the prototype level, particularly for propulsion systems, in both the automotive and aerospace sectors.

Cygnet Texkimp's Slitter Spooler Rewinder at the company’s U.K.-based Innovation Centre. Photo Credit: Cygnet Texkimp

Cygnet Texkimp (Northwich, U.K.), a specialist in advanced material manufacturing machinery, occupies a pivotal role as a consortium member, with expertise that aligns with ASCEND's theme of “rate-capable automation.” Its contributions to this initiative are distinctly geared toward achieving material manufacturing speeds that transcend current industry boundaries without sacrificing quality. The company is focusing on future material systems and high-rate-capable CFRP production methods which have potential to enable high-speed production of Type V hydrogen storage vessels, and thus, widespread adoption of hydrogen as an aerospace and automotive fuel.

Cygnet Texkimp has invested in developing next-generation material production systems in collaboration with other ASCEND players, namely GKN Aerospace (Redditch, U.K.) and McLaren Composites Technology Centre (Sheffield, U.K.). The initiative also examines the complete lifecycle of composites used within the automotive and aerospace industries. Moreover, it includes designing and implementing recycling and end-of-life composite fiber recovery solutions, closing the sustainability loop. Cygnet Texkimp has developed two systems within the ASCEND program: the Multi Roll Stack machine and a CFRP recycling system.

Multi Roll Stack evolution

Over the past decade, Cygnet Texkimp has deployed more than 30 production lines for unidirectional (UD) and woven fabric thermoset prepreg across the aerospace, automotive and industrial sectors. In a significant 2021 milestone, the firm introduced the Direct Melt Impregnation Thermoplastic Composite Line for producing high-quality thermoplastic composite prepregs, accommodating a broad polymer spectrum ranging from polypropylene to polyetheretherketone (PEEK). Cygnet Texkimp’s Multi Roll Stack is a derivative system optimized for the high-rate manufacture of CFRP within a filament winding cell optimized for Type V hydrogen storage tank manufacturing.

The Multi Roll Stack roller configuration increases the material/heated roller contact throughout the production process compared to other systems. Photo Credit: Cygnet Texkimp

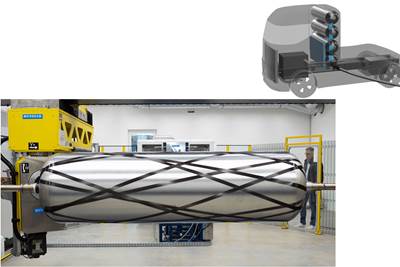

The filament winding cell is an assembly of interrelated machinery that collectively executes a gamut of functions, including spindle management, tie-on and tie-off operations, real-time splicing, resin dispensation, mandrel management, filament winding, curing, product quality inspection, traceability and product packaging. By integrating these independent tasks into a unified cell and coupling them with a monitoring apparatus, the system can achieve high-rate automated fulfillment of filament-wound products while upholding stringent accuracy and repeatability.

CFRP machine design

The Multi Roll Stack is engineered for precise fabrication and slitting of UD and woven fabric CFRP prepregs and towpregs, serving as the material feedstock for the filament winding cell. However, rather than relying on separate compaction stations arranged in a horizontal line, the Multi Roll Stack integrates multiple impregnation rollers within a single compaction module, vertically arrayed in an S-wrap configuration.

“The Multi Roll Stack’s architecture was designed to increase the material's contact with the heated rollers to maintain consistent temperature throughout the manufacturing process,” explains Cygnet Texkimp's CEO, Luke Vardy. “The S-wrap roller configuration features short pathways between rollers, almost eliminating the heating/cooling cycle seen in other inline prepreg technologies.” This vertical alignment of rollers within a singular compaction module also offers a considerable benefit in energy efficiency as the S-wrap configuration removes the need for multiple drive motors and heaters. The result is a quantifiable reduction in energy use — exceeding 50% when contrasted with traditional compaction methodologies. “This development gains prominence in light of escalating energy costs and a heightened emphasis on the environmental impact of manufacturing technologies,” notes Vardy.

The Multi Roll Stack is induction motor driven, operated in speed control rather than torque, configured for operational efficiency. Induction motors can freewheel, enabling operators to handle materials without disengaging electromagnetic components. That contributes to reduced processing time and minimizes the risk of material damage. Vardy underscores the precision that speed control provides in managing material tension. "The tension exerted on a fiber during its transition from one roller to the next is critical for the quality of the material produced,” he explains. “Motors operated in speed control offer precise tension governance vital for optimizing resin-to-fiber ratios. This parameter is rigorously managed by the S-wrap design, which considerably influences the mechanical properties of the resulting composite material."

Material results

Cygnet Texkimp's Multi Roll Stack machine can produce prepregs with a coat weight of 112 grams/square meter while achieving a 10 meter/minute production rate. "This signifies a doubling in the production speed compared to traditional machines,” says Vardy. “And yet the output from the Multi Roll Stack meets the properties required for aerospace-grade composite materials for Type V hydrogen tank construction — uncompromising strength-to-weight ratios, precise resin distribution and thermomechanical resilience.”

Cygnet Texkimp’s four-axis filament winding machine for producing CFRP hydrogen storage vessels. Photo Credit: Cygnet Texkimp.

The consistent temperature of the Multi Roll Stack’s S-wrap design also affords distinct advantages for fabric constructions, especially during subsequent forming processes. Vardy elaborates: "The S-wrap can automatically open and close the fabric weave, effectively preparing the material for draping around molds in its final forming process. This process ensures uniform resin impregnation, a factor critical for enhancing composite mechanical properties."

Material impregnation with epoxy resin also benefits from the S-wrap's thermal consistency, accelerating production timelines. "The S-wrap heats epoxy resins quickly and uniformly, inducing them to flow seamlessly into the fabric, thus expediting the time to production," explains Vardy. "Such resin flow and curing optimization positively impact interlaminar shear strength, a critical property for high-performance, filament-wound composite applications."

Cygnet Texkimp's Multi Roll Stack is combined with the company's four-axis filament winder technology to enable Type V tank manufacturing within one filament winding cell. Design options for Type V tanks are still under rigorous evaluation by the various industries looking to employ them. "Most manufacturers have reached the stage where they are determining tank dimensions and anticipated wall thickness," says Vardy. "The layup configurations often involve traditional fiber angles of +/- 45 degrees and interwoven layers at +/- 90 degrees. The choice of fiber orientation is a subject of ongoing research, especially considering its significant impact on the tank's burst pressure and fatigue life." He notes the filament winding cell enabled by Cygnet Texkimp’s ASCEND developments can manage all these orientations and offers flexibility for future designs.

End-of-life technology

In an industry where material performance is paramount, the sustainability facet of composites often takes a back seat. However, Cygnet Texkimp is challenging this narrative with its composite recycling system where valuable fiber can be reclaimed from the resin matrix without burning, chopping or weakening. The system leverages a B&M Longworth (Edgworth, U.K.) patented thermal-cyclic form of pressolysis called DEECOM to reclaim value waste streams from thermoplastic and thermoset polymers, allowing for reprocessing and remanufacture into high-grade items while meeting safety and strength demands.

The DEECOM process uses supercritical steam and swings of compression and decompression to attack the surface area of organic material, causing a physical fracturing of the polymeric contaminant. The thermal and pressure parameters governing DEECOM are extreme, with internal temperatures up to 600°C and pressures up to 15 bar.

Composite recycling system that uses thermal-cyclic form of pressolysis called DEECOM. Photo Credit: B&M Longworth

During each stage, the system’s pressure and steam content cause resin dissociation, forming a dissolved resin vapor. This vapor is then channeled into a condenser system, traversing a heat exchanger to create a water/resin liquid solution. What remains in the chamber are dry, long fibers, remarkably close in performance to virgin fibers.

Cygnet Texkimp’s composite recycling system is adept at extracting resin from a broad spectrum of fiber-reinforced polymers, extending from lightweight, thin products to intricately constructed, 50-millimeter-thick aerospace parts. Polymer — in the form of yarn, resin or binder — can be extracted from any component, which can be a metallic, carbon fiber, glass fiber or other composite parts.

“Post-DEECOM fiber sampling indicated retention of 94% tensile strength and 97% tensile modulus compared to virgin fibers,” notes Vardy. “The marginal performance deviation from raw virgin fiber performance is typically due to stresses induced during the manufacturing and in-service phases of the component.”

While not negligible, the energy cost of fiber reclamation is significantly less than that involved in generating long virgin fibers. Such efficiency gains are not trivial and underscore the economic and environmental benefits of composite material recycling. Cygnet Texkimp envisions incorporating the composite recycling units at the terminal points of its customers' virgin fiber production lines, enabling the recycling of waste products into valuable raw materials for sheet molding compound (SMC) parts or similar components.

Vardy highlights that the composite recycling system effectively strips fibers from all current forms of a CFRP composite. “It is capable of stripping a single-ply prepreg of its resin in mere hours, and while high-performance aerospace parts necessitate a more protracted process, the fibers can still be reclaimed,” he says. “In an industry often described as resource-intensive, our composite recycling system introduces a compelling chapter in the pursuit of sustainability without compromising rigorous material performance standards.”

ASCEND first steps toward future composites

Although reticent on specifics concerning how its Type V hydrogen storage tanks will be manufactured, Vardy acknowledges this project's pivotal role in the future of hydrogen energy. “The Multi Roll Stack's high-performance composite production rate epitomizes the ASCEND program's desire for the fusion of speed, cost-effectiveness and uncompromised material quality, crystallizing our understanding of material science across every production phase,” reflects Vardy. Meanwhile, he says, the composite recycling system demonstrates how these pursuits can be elegantly balanced with long-term sustainability in a market often dictated by the relentless pursuit of efficiency and quality. These first developments within ASCEND signal a future where composite excellence and sustainability are not mutually exclusive but complementary facets of technological evolution.

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreNCC reaches milestone in composite cryogenic hydrogen program

The National Composites Centre is testing composite cryogenic storage tank demonstrators with increasing complexity, to support U.K. transition to the hydrogen economy.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRead Next

Hexagon Purus Westminster: Experience, growth, new developments in hydrogen storage

Hexagon Purus scales production of Type 4 composite tanks, discusses growth, recyclability, sensors and carbon fiber supply and sustainability.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More