Bioabsorbable and degradable glass fibers, compostable composite parts

ABM Composite offers sustainable options and up to a 60% reduction in carbon footprint for glass fiber-reinforced composites.

Share

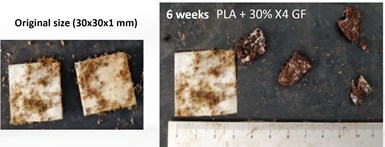

Bioabsorbable bone fixation implant made by ABM Composite (top left) and automotive brake pedal (right) made using ArcBiox BGF30-B1 long fiber technology (LFT) compound comprising polylactic acid (PLA) reinforced with ArcBiox X4 degradable glass fibers. ArcBiox BGF30-B1 passed industrial compost testing per standard EN 13432, conducted by DIN CERTCO/TUV in Germany. Photo Credit, all images: ABM Composite

What if glass fiber-reinforced polymer (GFRP) composites could provide the improvement in lightweight, strength and stiffness, corrosion resistance and durability that has been proven for decades, but also be composted at the end of their service life? This is indeed what ABM Composite is offering.

Bioactive glass, high-strength fibers

Arctic Biomaterials Oy (Tampere, Finland) was founded in 2014. It developed a degradable glass fiber made from what is called bioactive glass, says Ari Rosling, R&D director for ABM Composite. “This is a specific formulation developed during the 1960s that enables the glass to degrade within physiological conditions.” When inside the body, the glass breaks down into its component mineral salts, releasing sodium, magnesium, phosphate, etc. This then creates a condition which stimulates bone growth.”

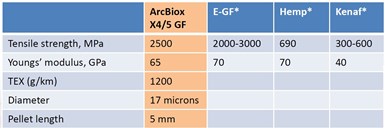

“Its properties are similar to E-glass,” says Rosling, “but this kind of bioactive glass is very difficult to make and draw into fiber. Previously, it was only used as a powder or putty. To our best knowledge, ABM is the first company to make high-strength glass fibers from it on an industrial level and we now use these ArcBiox X4/5 glass fibers to reinforce different types of plastics, including biodegradable polymers.”

Medical implants

This part of Finland, a 2-hour drive north of Helsinki, has been the center of bio-based biodegradable polymers for medical applications since the 1980s, says Rosling. “One of the first commercial implants made using these materials was produced here in Tampere. And that is how ABM Composite started, which is now our medical business unit.”

“There are a lot of biodegradable, bioresorbable polymers that are used for implants,” he continues. “But their mechanical properties are far from those of natural bone. We are able to reinforce these biodegradable polymers so that the implants have the same strength as natural bone.” Rosling notes that adding ABM’s medical grade of ArcBiox glass fibers can provide a 200-500% increase in the mechanical properties of biodegradable poly-L-lactic-acid (PLLA) polymer.

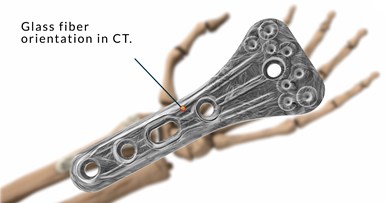

Thus, ABM Composite’s implants have higher performance than those made from unreinforced polymers, while also being bioabsorbable and promoting bone formation and growth. ABM Composite also uses automated fiber/strand placement technology to ensure that fibers are oriented optimally, including fiber spanning the whole implant length and placing additional fiber at potential weak spots.

Household and technical applications

While its medical business unit was growing, ABM Composite recognized that bio-based and biodegradable polymers were also being used for kitchenware, utensils and other household items. “Here also, the mechanical performance of these biodegradable polymers is often inferior compared to petroleum-based plastics,” says Rosling. “But we can reinforce these with our degradable glass fiber so that they are actually good alternatives to fossil-based commodity plastics for a wide range of technical applications.”

ABM Composite thus added its technical business unit and has now grown to a total of 60 employees. “We provide more sustainable end-of-life [EOL] options,” notes Rosling. “The value proposition is that we can place these biodegradable composites into industrial compost operations, where they turn into soil.” Traditional E glass is inert and would not degrade in these compost facilities.

ArcBiox fiber composites

ArcBiox X4/5 glass fiber is available in chopped and continuous formats, the latter used in processes such as weaving and pultrusion, seen at bottom right with bio-based polyester resin.

ABM Composite has developed ArcBiox X4/5 glass fiber in a variety of formats for composites, ranging from chopped fibers and injection molding compounds to continuous fibers for processes like textile weaving and pultrusion. Its ArcBiox BSGF series combines the degradable glass fiber with bio-based polyester resin, available in a general technical grade and the ArcBiox 5 grade approved for food contact.

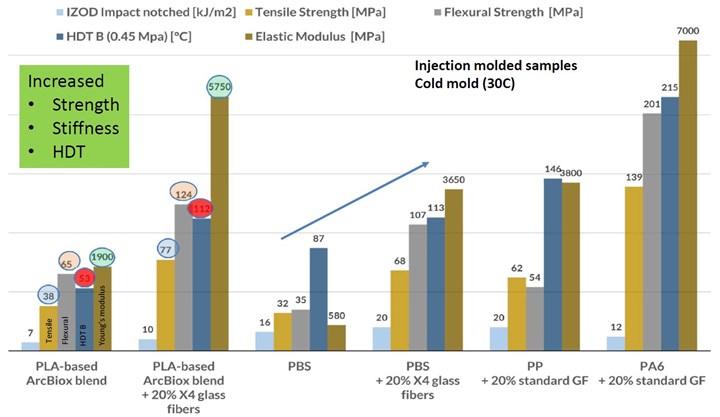

ABM Composite has also worked with a variety of biodegradable and bio-based polymers, including polylactic acid (PLA), PLLA and polybutylene succinate (PBS). The graph below shows how X4/5 glass fibers increase performance to be competitive with standard glass fiber-reinforced polymers such as polypropylene (PP) and even polyamide 6 (PA6).

Rosling notes that bio-based PP and PA — production of which is rapidly increasing — do not degrade. “And though bio-based PLA and PBS will degrade, their mechanical properties and heat resistance are often very low. Our degradable glass fiber has been a huge step forward, sufficiently improving their performance to enable new applications.”

Durability versus compostability

If these composites are biodegradable, how can they be durable? “Our X4/5 glass fiber is not like sugar that will dissolve within five minutes or overnight,” says Rosling. “Its properties will reduce over time, but not that dramatically. To efficiently degrade, we need prolonged elevated temperature and humidity, as you would find inside the body or an industrial compost pile. For example, we have tested cups and bowls made with our ArcBiox BSGF materials, and they can withstand up to 200 dishwashing cycles without losing functionality. The mechanical properties were reduced to some extent, but not so much that the cups could no longer be safely used.”

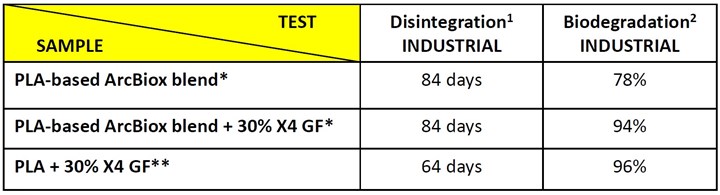

During Industrial compost testing, ABM Composite ArcBiox materials using X4 glass fiber met standards requiring disintegration to pieces <2 millimeters and 90% biodegradation (measured by carbon content) within 90 days.

* cold mold injection molded

** crystalline material hot injection molded

1 Disintegration per UNI EN ISO 20200:2016; MP 2238 rev 0 2017

2 Aerobic biodegradability test per ISO 14855-1:2012

However, it is important that when these composites are treated at the product’s EOL, they do indeed meet the required standards for composting. ABM Composite has performed a series of tests to prove it meets these standards. “According to ISO standards (industrial compost), biodegradation should happen within 6 months and disintegration within 3 months/90 days,” says Rosling. “Disintegration means the test sample/product is placed into a biomass or compost. After 90 days, the test is made by technicians passing the biomass through a sieve/mesh. After 12 weeks at least 90% of the product should be able to pass through the 2 × 2 millimeter mesh.”

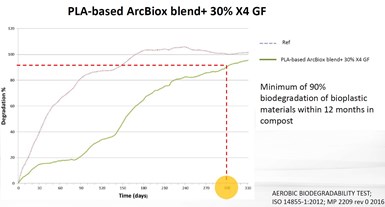

Biodegradation is determined by grinding the original material into a powder and measuring the total amount of CO2 released after 90 days. This allows assessing how much carbon content has been converted to water, biomass and CO2 during composting. “To pass the industrial compost test,” says Rosling, “90% of the theoretical 100% CO2 (calculated from the carbon content) must be reached during composting.”

ABM Composite has passed requirements for both disintegration and biodegradation, says Rosling, noting that tests showed adding its X4 glass fiber actually improved biodegradation (see table above). “For example, an unreinforced PLA blend only reached 78%,” he explains, “but when we added 30% of our degradable glass fiber, biodegradation increased to 94% while the disintegration remained good.”

Thus, ABM Composite has demonstrated that its materials can be certified as compostable per the EN 13432 standard. Tests its materials have passed so far include:

- Controlled aerobic composting (biodegradation) test ISO 14855-1

- Controlled aerobic disintegration ISO 16929

- Chemical requirements ISO DIN EN 13432

- Plant test (ecotoxicity test) OECD 208, ISO DIN EN 13432

ABM Composite has also proven that plants grown in its composted materials have no toxicity (top) and passed requirements for aerobic biodegradation under home composting conditions (bottom).

Ecotoxicity requires testing of the biomass formed during composting and of plants grown using this biomass. “This is to ensure that compost from these products does not cause any harm to growing plants,” says Rosling. In addition, ABM Composite has proven its materials meet biodegradation requirements using home composting conditions, which again require 90% biodegradation but within 12 months versus the shorter timeframe for industrial compost operations.

Industrial applications, production, cost and future growth

ABM Composite materials are being used in a range of commercial applications, but many more are covered by nondisclosure agreements. “We have tailored our materials to fit sectors such as cups, dishes, cutlery and food storage boxes,” says Rosling, “but they are also being used in cosmetic containers and in larger household items, as an alternative to petroleum-based plastics. More recently, we’ve been selected for parts in large industrial machinery installations. These are parts that need to be changed every two to 12 weeks. Companies have recognized that, due to the reinforcing impact of our X4 glass fiber, such machinery parts can actually be made with the abrasion and wear resistance required yet still be composted after use. This is an attractive near-term solution as companies are being challenged to meet new environmental and CO2 regulations.”

“There is also growing interest to use our continuous fibers in different types of textiles and nonwovens to make structural components for building and architecture applications,” adds Rosling. “We’re also seeing interest to use our degradable fiber with bio-based but nondegradable PA or PP as well as inert thermosets.”

Currently, X4/5 glass fiber is more expensive than E-glass fiber, but production is also relatively small. ABM Composite is pursuing multiple opportunities to expand applications and could readily scale to 20,000 metric tons/year as demand grows. This will also help to lower cost. Even so, Rosling points out that the cost of sustainability and meeting new regulations isn’t yet fully considered in many cases. Meanwhile, the urgency to save our planet is increasing. “Society is already pushing for more bio-based products,” he explains. “There are so many incentives pushing circular technology forward now, and the world needs it to go faster. “I think society will only increase its push toward more bio-based products for the future.”

LCA and sustainability advantage

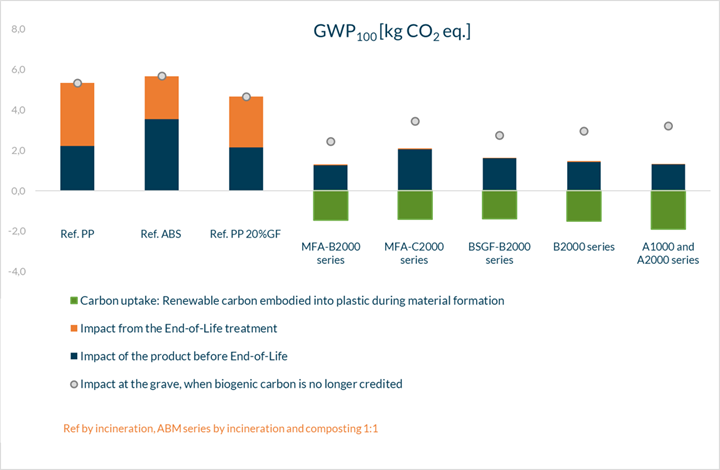

Rosling says ABM Composite materials can reduce greenhouse gases produced and non-renewable energy used by as much as 50-60%, per kilogram of material. “We are performing LCA [lifecycle analysis] calculations on our products using Environmental Footprint Database 2.0, accredited GaBi datasets and according to the approaches outlined in ISO 14040 and ISO 14044.”

The figure above shows the difference between fossil fuel-based polymers at left versus development ABM Composite materials at right. The large orange blocks at left represents non-renewable CO2 released during EOL incineration, while the large green data at right reflects generation of renewable CO2 embodied into the products during manufacture.

“Right now, a significant amount of energy is required at composites end of life to incinerate or pyrolize composites waste and EOL products,” says Rosling. “Shredding and composting is an interesting alternative. That’s definitely one of the big value propositions that we offer. We’re offering a new type of circularity. Our glass fiber is made out of natural mineral components that are already present in the soil. So why not compost EOL composite parts, or dissolve our fiber from non-degradable composites after incineration and use it as a fertilizer? This is a recycling option that is really creating interest around the world.”

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Natural fiber composites: What’s holding them back?

Natural fiber reinforcements have been available for some time, but factors such as compatibility with current processes and geographic availability continue to limit widespread use.

Read MoreBiodegradable, biobased Ekoa composite veneers are in production

Ekoa 99.7% bio-based veneers are used to finish surfaces in walls, ceilings, furniture and vehicle interiors.

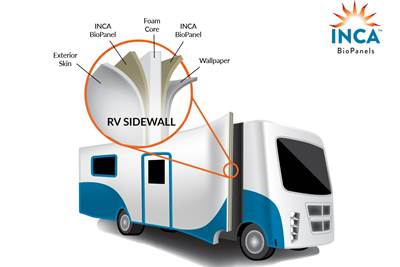

Read MoreStudy reports INCA Renewtech hemp-based biocomposites radically reduce carbon emissions

Compared to lauan rainforest plywood, INCA’s BioPanels are reported to reduce carbon emissions, waste production and water consumption.

Read More