Aalto University researchers develop technique for creating colored carbon nanotube films

The team’s method uses aerosols of metal and carbon to carefully manipulate and control the nanotube structure directly from the fabrication process.

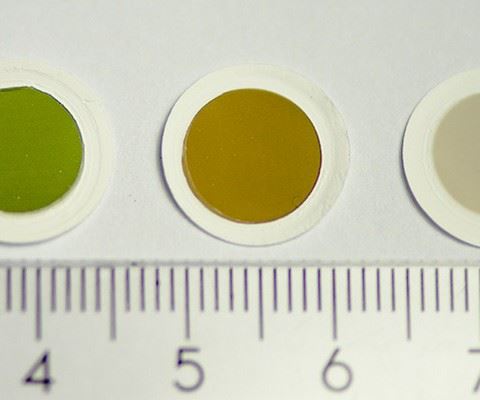

In a new study published in the Journal of the American Chemical Society (JACS), Aalto University (Espoo, Finland) researchers present a way to control the fabrication of carbon nanotube thin films so that they display a variety of different colors—for instance, green, brown or a silvery grey.

Carbon nanotubes, which are used in many electronics and touch screen devices, are typically black or dark grey and the Aalto University researchers believe this is the first time that colored carbon nanotubes have been produced by direct synthesis.

Using their invention, the color is induced straight away in the fabrication process, not by employing a range of purifying techniques on finished, synthesized tubes. With direct synthesis, large quantities of clean sample materials can be produced while also avoiding damage to the product in the purifying process—which makes it the most attractive approach for applications.

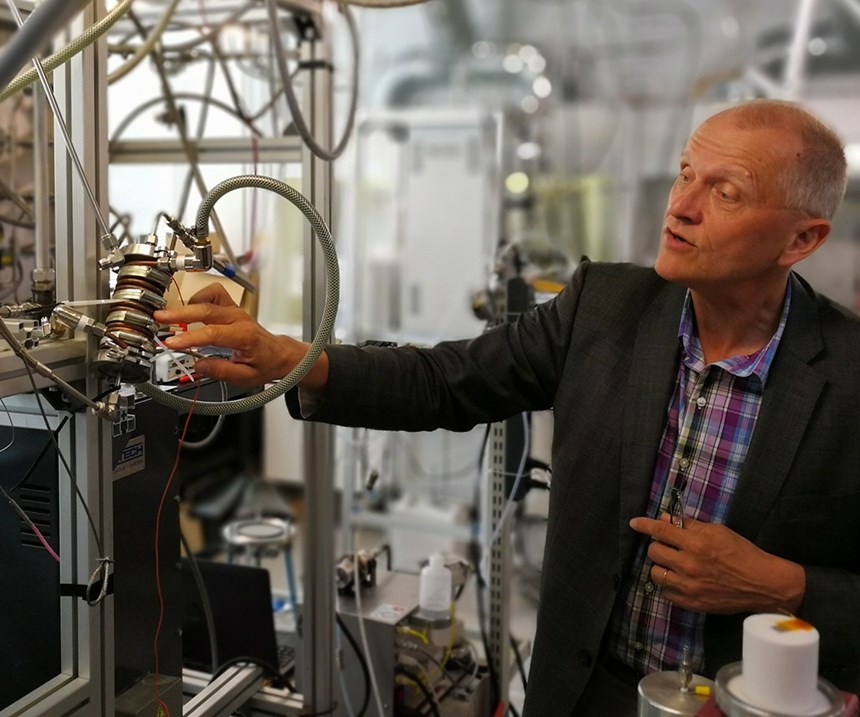

“In theory, these colored thin films could be used to make touch screens with many different colors, or solar cells that display completely new types of optical properties,” says Esko Kauppinen, professor at Aalto University.

The underlying techniques needed to enable the coloration also imply finely detailed control of the structure of the nanotube structures. Kauppinen and his team’s method, which uses aerosols of metal and carbon, allows them to carefully manipulate and control the nanotube structure directly from the fabrication process.

“Growing carbon nanotubes is, in a way, like planting trees – we need seeds, feeds,\ and solar heat. For us, aerosol nanoparticles of iron work as a catalyst or seed, carbon monoxide as the source for carbon, so feed, and a reactor gives heat at a temperature more than 850°C,” says Dr. Hua Jiang, senior scientist at Aalto University.

Professor Kauppinen’s group has recently experimented with administering small doses of carbon dioxide into the fabrication process.

“Carbon dioxide acts as a kind of graft material that we can use to tune the growth of carbon nanotubes of various colors,” explains Jiang.

With an advanced electron diffraction technique, the researchers were able to find out the precise atomic scale structure of their thin films. They found that they have very narrow chirality distributions, meaning that the orientation of the honeycomb-lattice of the tubes’ walls is almost uniform throughout the sample. The chirality more or less dictates the electrical properties carbon nanotubes can have, as well as their color.

The method developed at Aalto University promises a simple and scalable way to fabricate carbon nanotube thin films in high yields. Follow-up work is underway.

“We want to understand the science of how the addition of carbon dioxide tunes the structure of the nanotubes and creates colours. Our aim is to achieve full control of the growing process so that single-walled carbon nanotubes could be used as building blocks for the next generation of nanoelectronics devices,” says professor Kauppinen.

Related Content

-

FACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

-

Inha University incorporates SwiftComp simulation software to virtually test composites

AnalySwift’s SwiftComp tool aims to mitigate the burden of costly experiments and enable accurate testing of woven and braided composite structures.

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.