AnalySwift receives U.S. Navy grant to help improve service life of helicopters

The funded project aims to further develop SwiftComp modeling software to better predict the durability of composite flexbeams on Navy rotorcraft.

Source | AnalySwift

AnalySwift LLC (West Jordan, Utah, U.S.), a Purdue University-affiliated commercial software provider, has received a $240,000 Small Business Innovation Research program grant from the U.S. Navy to help the company further develop its SwiftComp modeling software for use with Navy rotorcraft. The specific project is aimed at advancing the software to better predict the durability of flexbeams made from composite materials.

“We are excited to partner with the U.S. Navy to help address this challenge,” says Allan Wood, president and CEO of AnalySwift. “The Navy is going to be able to use the resulting software technology to properly align a helicopter’s predicted life to actual service life, reduce downtime in redesigns and, ultimately, save money.”

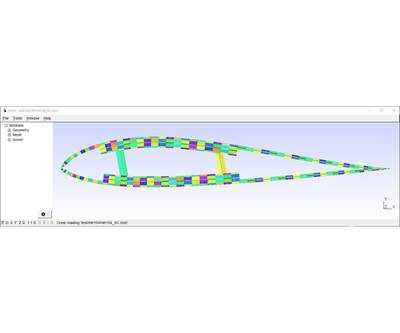

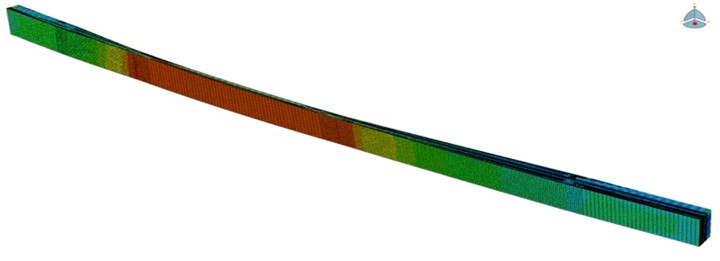

The helicopter flexbeam is the critical component that connects the blade with the hub. According to AnalySwift, flexbeams made from composites are particularly difficult to design and analyze due to their complexity, including their tapered and curved nature and complex microstructures.

While NAVAIR policy for durability determined by analysis typically requires the analysis to show four times the service life required, AnalySwift says that in reality, testing shows actual life well below required service life and what was analytically predicted. This discrepancy between predicted life and tested life costs both time and money in redesign. Attempts to correct these shortcomings have shown little success, AnalySwift says.

Source | AnalySwift

“Our specific project aims to enable an efficient high-fidelity tool set with significantly improved durability predictive capabilities for composite flexbeams using user-defined elements,” Wood says. “Success of this proposal will produce a practical solution for efficient yet accurate durability analysis of composite flexbeams.”

In addition to better strength and durability analysis for curved and tapered composite structures such as composite flexbeams, the project aims to enable:

- Significantly reduced time and cost used for design and redesign of complex composite structures.

- More insightful guidance for experiments in understanding the effects of ply drop-offs and other defects of composite flexbeams.

- More explicit modeling of internal features and defects, easy handling of hybrid materials and direct incorporation of new material models.

- Although the direct commercial application is durability analysis of composite flexbeams used by the Navy, the proposed work will have many other potential commercial applications:

- Composite helicopter rotor blades, which are usually tapered with ply drop-offs along the span-wise direction.

- Composite wind turbine blades with cross-sections varying significantly.

- Complex composite structures featuring non-uniform cross sections used in aerospace, automotive, and sports.

- Thick composite structures where ply-level stress and durability prediction is critical.

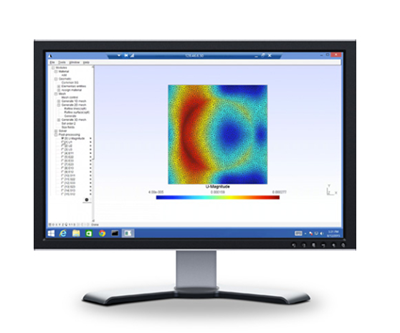

“One of the advantages of the SwiftComp software is its ability to carry out efficient high-fidelity multi-scale modeling for structures featuring complex microstructures,” says Wenbin Yu, professor of aeronautics and astronautics in Purdue’s College of Engieering, and creator of SwiftComp technology. “SwiftComp takes details of the fundamental building block of materials and structures as input, then outputs the structural properties needed for macroscopic analysis. It can be used for composite beams, plates and shells, and 3D structures, for both micromechanical and structural modeling. This project will help expand the application of SwiftComp even further for composites used in rotorcraft and other applications with curved or tapering structures, as well as applications where a clear understanding of durability is critical.”

The software also has been licensed to companies and universities worldwide, including those using it for work on satellites and mobile phone components, including printed circuit boards.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

AnalySwift receives NASA grant to improve design of composite deployable structures

The $125,000 grant will further development of SwiftComp software to improve modeling and design for deployable structures built from high-strain composites.

Read MoreAnalySwift launches academic partner program for composites simulation software

Through its Academic Partner Program, AnalySwift now offers universities no-cost licenses for its SwiftComp and VABS tools for academic research.

Read MoreCarleton University leverages VABS software for helicopter blade simulation

As part of AnalySwift LLC’s Academic Partner Program, Carleton University is working on new comprehensive software to simulate helicopter blade tasks.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)