Arris co-founder develops composite rock climbing gear

Passion for rock climbing leads to durable, 30% lighter cam using Additive Molding.

Inspired by two decades of outdoor rock climbing, Arris Composites’ (Berkeley, Calif., U.S.) co-founder and chief engineer, Erick Davidson, sought to develop cams — trad protection designed to be placed in parallel-sided cracks in rock to support climbing — that were lightweight, high performance and were large enough to ensure climbers felt safer in wide cracks. His work at Arris has led to a composite cam developed via Additive Molding.

Davidson, who leads the design, simulation, prototyping and tooling teams in Berkeley and Taiwan, did his Master’s work in composites at UC Berkeley. He gained experience at several technology startups before co-founding Arris. During the early days at Arris, he also founded a small company specializing in the fabrication of very large cams for the climbing community.

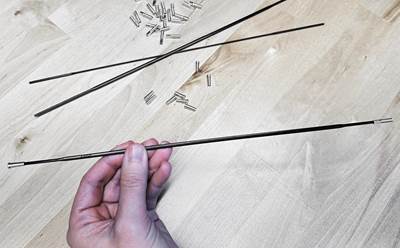

A cam traditionally has three or four curved pieces of metal called lobes. A spring-loaded trigger wire retracts the lobes as needed to make the device narrower, and then expands outward to release and fit the rock, once the trigger is released. Traditionally, cam lobes are made from aluminum due to its frictional properties and high-specific strength.

“Climbers are always after lighter gear, so composites seemed like a natural fit, but there wasn’t a composites technology suitable for making cam lobes until Arris,” explains Davidson. “I immediately recognized the potential of the technology for making cam lobes as they appear to be an ideal geometry for aligned continuous thermoplastic composites, but a few years passed before I took on the challenge as a personal project.”

After making and testing a few carbon fiber cams in the lab on the weekends, Davidson knew he had to get outdoors for the real test. Planning a week-long climbing vacation, Davidson and his wife decided to venture farther than their usual weekend destination, Yosemite. They chose Red Rocks near Las Vegas, a familiar spot with great cracks, ideal for testing the carbon fiber cams.

“Having tested the cams in the lab and seeing them perform well, I was confident they would perform outdoors,” says Davidson. “Still, the lab testing is an idealized setup, so you can never be entirely sure without doing some actual climbing.”

Davidson’s wife, the avid off-width climber, went after challenging pitches with the Arris carbon fiber cams and experienced no issues with handling or placement. The cams were so light she had to double-check to ensure she had selected the correct one. “At 30% weight savings,” says Davidson, “these carbon fiber cams weigh less than the next smaller size aluminum cams.”

Additionally, Davidson is pleased with the performance of the integrated aluminum friction strip. The aluminum interface, essential for its friction and wear properties, is co-molded onto the composite lobes and has exceeded his expectations.

“To find innovative solutions to these types of projects, you have to have an intimate knowledge of the use case,” adds Davidson. “Climbing cams are definitely a challenging use case. You have to trust cams to protect you from potential serious injury or even death in a fall, but they also have to withstand a certain amount of abuse inherent to the environment. And, it took time to determine how to make these robust enough to trust them. The thermoplastic matrix exhibits the toughness required for this application.”

In addition to more lab testing and extensive practical testing on future climbing trips — Davidson and his wife have several climbs lined up in Yosemite, and in the fall, they plan to visit Indian Creek, known for its abundance of 5-inch splitters — Davidson hopes to continue testing the capabilities of his novel cam innovation, even replacing other metal components with carbon fiber.

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Filament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreComposite accelerator pedal enhances Formula SAE performance

Venox Systems was brought into the fold to deliver a 3D printed continuous carbon fiber/PEKK pedal for the TU Wien Racing Team that exceeded its aluminum counterpart.

Read MoreArris introduces MTO CFRTP bike spokes

Lightweight carbon fiber spoke is designed, engineered and manufactured using Arris’ Additive Molding technology.

Read More

.jpg;maxWidth=300;quality=90)