Arris introduces MTO CFRTP bike spokes

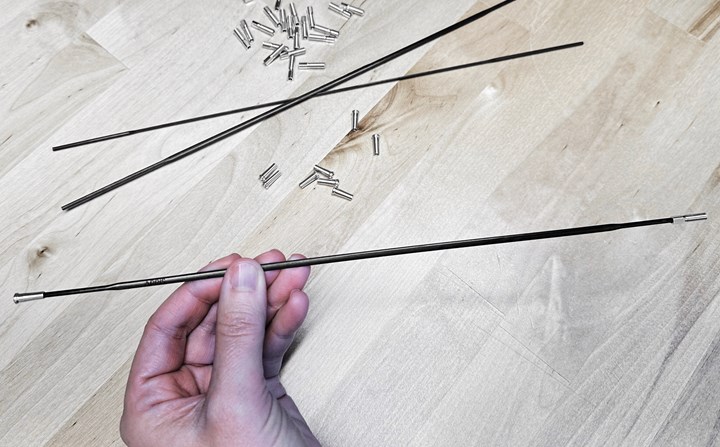

Lightweight carbon fiber spoke is designed, engineered and manufactured using Arris’ Additive Molding technology.

Arris Composites (Berkeley, Calif., U.S.) introduces Arris | Made to Outperform (MTO) bicycle spokes. The product line, made from carbon fiber-reinforced thermoplastics (CFRTP) using Arris’ software, materials and manufacturing technology platform Additive Molding, includes multiple options for weight and performance advantages — for example Arris contends that its spokes are 2.7X stronger gram for gram than the metal spoke available today.

Arris reports that its team was hands-on in every aspect of the spokes’ development, from material development to design, as well as engineering and production. Multiple test rides, in the lab and on the trail, indicate the CFRTP spokes’ light weight and durability can provide an overall optimized performance quality to bike wheelsets.

Arris has also recently been recognized for the CFRTP spokes as a 2024 Big Innovation Award winner by the Business Intelligence Group for the fourth year in a row.

The company works in multiple applications and end markets, including drones, airplanes, footwear, bicycles and more (read “Plant tour: Arris Composites, Berkeley, Calif., U.S.”).

Related Content

-

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

-

Developing repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.