AZL Aachen investigates potential for bio-based composite materials

The five-month market and technology study will start on October 22, 2020 and is open to interested companies.

Share

Read Next

Photo Credit: AZL Aachen

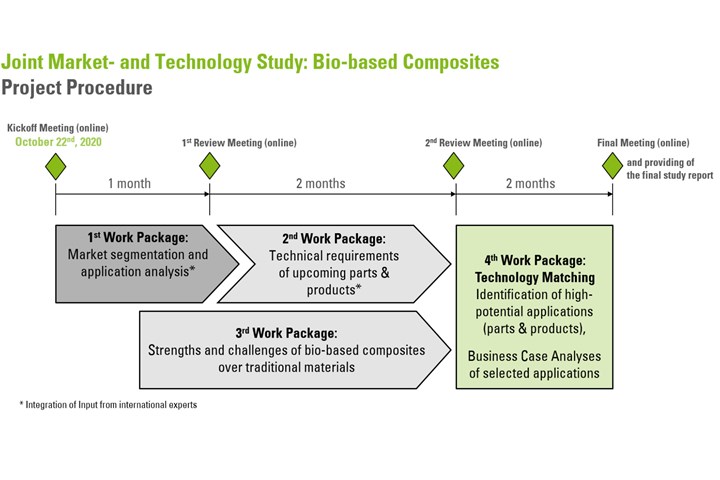

It was reported on Sept. 24 that in order to obtain a comprehensive evaluation of the potential of bio-based composites, service provider for lightweight technology and business development AZL Aachen (Aachen, Germany), together with an industry consortium, is investigating the market potential, future applications and relevant technologies for bio-based composite materials. The five-month market and technology study will start on October 22, 2020 and is open to interested companies. Companies such as REHAU (Muri bei Bern, Switzerland), an automotive Tier 1, Asahi Kasei (Tokyo, Japan), Johns Manville (Denver, Color., U.S.), Mahr Metering Systems (Charlotte, N.C., U.S.) and several material manufacturers are participating in the study.

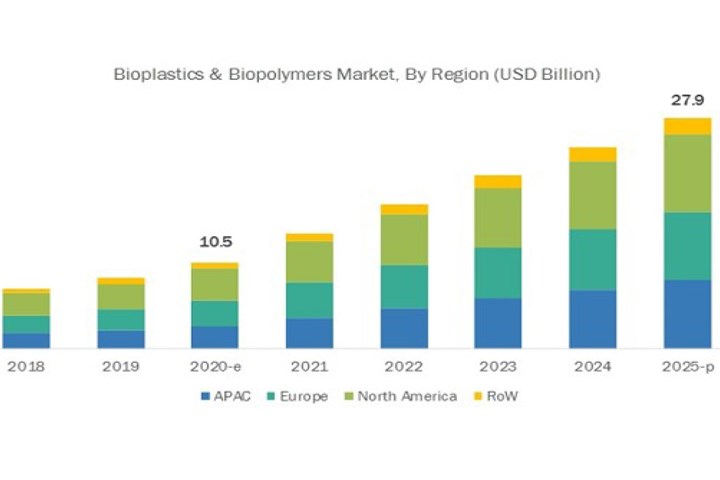

According to the AZL, bio-plastics are well established in the industry, including in packaging applications. The market for biopolymers is expected to grow from USD $10.5 billion in 2020 to USD $27.9 billion in 2025. At the same time, says the AZL, bio-based raw materials, such as natural fibers, are available on the market in a cost-effective manner. Composites with wood or natural fiber content are also increasingly used in products.

"Together with our partner companies we want to identify hidden business potential for composites with bio-based materials. To do so, we will reapply our established approach for market and technology studies: Based on a detailed market analysis, we will dive deep into the technological evaluation of technologies, applications and business cases,” says Dr. Michael Emonts, managing partner of AZL.

Photo Credit: AZL Aachen

Based on a detailed market segmentation, AZL says its technology experts analyze the various market segments in terms of their size, growth potential, relevant players and existing and future applications. For the identified applications, the participants in the study will receive detailed insight into the respective technical and legal requirements as well as an overview of value chains, processes and materials. In the following, the strengths and challenges of bio-composites compared to conventional materials are elaborated. The consortium will select the components with the highest potential, for which suitable production scenarios will be developed and analyzed in terms of costs in a business case analysis.

"We are participating in the AZL study to identify and evaluate new product areas with bio-materials. The technological analyses of the AZL studies have already helped us in the past to initiate new developments," says Dr. Steven Schmidt, director Technology Platforms Materials at REHAU, explaining the motivation for working with the AZL and the industry consortium. "As one of the 50 Sustainability and Climate Leaders, we at REHAU are incorporating environmentally friendly materials into more and more products. Wherever the company is active — from the furniture and construction industries to the automotive industry — REHAU is already developing and manufacturing high-quality products from recycled raw materials. By 2025, REHAU plans to increase its recycling rate across the Group to more than 15% and at the same time reduce CO2 emissions by at least 30%.”

AZL notes that bio-composites will also be the topic of the upcoming Lightweight TechTalk by AZL on September 29, 2020. Experts from industry and academia will give technology and market insights on sustainability and recycling of composites in six presentations. Registration is free of charge here.

This post is courtesy of the CompositesWorld and AZL Aachen GmbH media partnership.

Related Content

BiDebA project supports bio-based adhesives development for composites

Five European project partners are to engineer novel bio-based adhesives, derived from renewable resources, to facilitate composites debonding, circularity in transportation markets.

Read MoreBiomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreKCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreRead Next

AZL begins multi-material battery casing project for electromobility

The eight-month joint development project will begin with a concept study for the final design and manufacture of the prototype. Interested companies can initiate participation until October 22, 2020.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More