Bell starts operations at new Manufacturing Technology Center

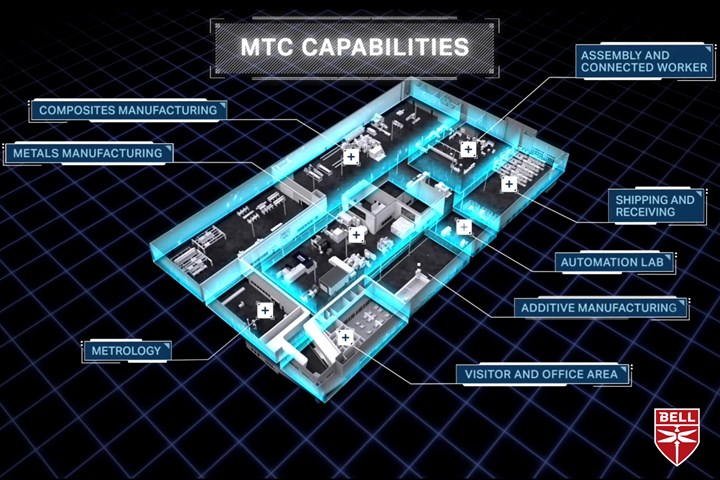

Composites and metals manufacturing, automation, additive manufacturing and metrology will be undergirded by digital connectivity and digital twin to support affordable production of future vertical lift aircraft.

Photo Credit: Bell Textron

Bell Textron has celebrated the start of operations at its state-of-the-art Manufacturing Technology Centre (MTC) at its Fort Worth, Tex., U.S. location with a small gathering and ribbon-cutting ceremony. This event marks the next milestone in the development of the 140,000-square-foot MTC before its grand opening, targeted for summer 2021.

“Through the Manufacturing Technology Center, we can showcase how we will deliver the most affordable, capable and reliable aircraft for the warfighter,” says Mitch Snyder, president and CEO, Bell. "As we work together to define the next generation of Bell products, it's been gratifying to watch this new facility become a reality."

The MTC is an innovative proving ground where Bell will test and refine technologies and processes and also demonstrate readiness and ability to successfully build and support Future Vertical Lift (FVL) aircraft and other new products. The facility provides capabilities that span all of Bell’s core manufacturing of rotor and drive systems, critical infrastructure and final assembly. It offers a digitally connected space for collaboration between Bell teams in an environment that promotes smart risk taking. New systems will be tested and vetted for production suitability before being introduced to Bell's future factories. Bell broke ground on the facility in August 2020 and anticipates the facility to be fully operational later this year.

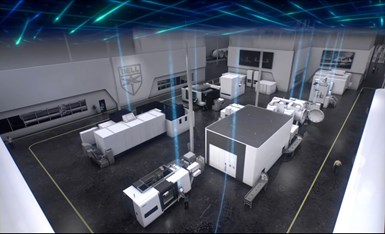

Bell’s new Manufacturing Technology Center will include metals and composites manufacturing (see autoclave just below upper right corner) with a focus on digital technology and automation. Photo Credit: Bell Textron

“The MTC is the next step in successfully deploying new manufacturing technologies and processes into Bell’s future factories,” says Glenn Isbell, vice president, Rapid Prototyping & Manufacturing Innovation. “These future factories working together with our teammates and suppliers, will be designed to enable high-quality, high-rate production of the Bell V-280 Valor, Bell 360 Invictus and other future aircraft.”

Digital connectivity and integration form the backbone of the MTC. Every inch of the facility will be monitored and controlled by a network of IT, Internet of Things (IoT) and cybersecurity systems that manage the inflow and outflow of materials, as well as the movement of activity throughout the factory. By deploying a networked software infrastructure, the MTC will produce a digital twin of itself that gives everyone a common operating picture of the building, the equipment and the processes.

Since establishing a footprint in North Texas in 1951, Bell’s facilities have been a hub for new technology in aviation. Many milestones, including first flight of the XV-15, V-22, 609 and 407, which took place in the Dallas-Fort Worth metroplex. Building FVL aircraft will require the right blend of investment in manufacturing technology and a quality workforce, as well as strong partnerships with the state and community, to deliver an affordable, capable and reliable aircraft for the warfighter.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;maxWidth=300;quality=90)