BMW unveils new M4 GT4 race car, features most natural fiber parts for GT series to date

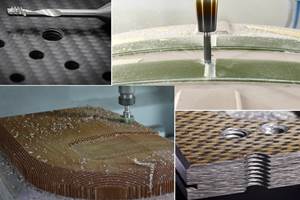

Bcomp ampliTex and powerRibs technologies make up bodywork components such as the hood, front splitter, doors, trunk and rear wing and several interior components, taking next steps for future production models.

BMW (Munich, Germany) announced that it has launched the successor of its M4 GT4 race car. With Bcomp’s (Fribourg, Switzerland) recent incorporation as an official BMW M Motorsport partner, this next evolution of the M4 GT4 series has taken sustainability to a new level, extensively using Bcomp’s ampliTex and powerRibs natural fiber composite technologies for a range of vehicle components.

BMW says it first started to work with Bcomp’s materials in 2019 when incorporating the high-performance fibers in the company’s iFE.20 Formula E car. From this flax fiber-reinforced cooling shaft, the collaboration evolved and soon after, ampliTex and powerRibs natural fiber solutions were found to successfully substitute selected carbon fiber components in DTM touring cars from BMW M Motorsport. The M4 GT4 is said to be the latest in a line of vehicle programs that this material has been expanded into.

BMW contends that the serial GT car has the highest proportion of natural fiber components to date. Bcomp’s ampliTex and powerRibs solutions can be found throughout the interior on the dashboard and center console, as well as on bodywork components such as the hood, front splitter, doors, trunk and rear wing. Aside from the roof, BMW notes that there is almost no carbon fiber-reinforced plastic (CFRP) components that were not replaced by natural fibers.

“Product sustainability is increasing in importance in the world of motorsport, too,” Franciscus van Meel, chairman of the board of management at BMW M GmbH, says. “So, we are delighted to have Bcomp on board as an official BMW M Motorsport partner for the BMW M4 GT4 project.”

According to the company, the use of natural fibers reduces greenhouse gas (GHG) emission reductions from cradle to gate up to 85% while adding performance benefits like improved vibration damping. Ductile failure mode without sharp debris and splinters, and stiffened parts also reduce dangerous debris upon impact during crashes, enhancing driver safety. Moreover, as the natural fiber components reach their end of life, BMW says they can be processed through the standard waste management system.

Taking the findings and experience gained on the track as a basis, the material technologies will also find their way into BMW M models, and BMW M Performance Parts, as stated by BMW Group. The development collaboration between BMW Group Research and Bcomp is also working on the use of new sustainable material solutions for future production models. Developing such innovative materials forms a key element of the sustainability strategy of the BMW Group, which is seeking to lower its vehicles’ life cycle carbon emissions by more than 40% by 2030 compared to 2019 levels.

“We are honored and happy to look back on such exciting joint milestones and even more on the adventures lying ahead of us with BMW,” Johann Wacht, manager motorsports and supercars at Bcomp, says. “Proving the performance of ampliTex and powerRibs on the highest level of Formula E and the DTM Class 1 era, and now embracing natural fiber parts to such a high extent on the new M4 GT4 customer racing program is a consequent and unparalleled statement towards scaling sustainable lightweighting.”

Related Content

Melker of Sweden accomplishes sea kayak with 100% sustainable composite construction

Built with ampliTex flax fabrics, a solid cork core and plant-based resins, the company’s Värmdö kayak model highlights an environmentally conscious design for paddlers of all levels.

Read MoreDITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more

The German Institutes of Textile and Fiber Research are targeting more sustainable carbon fiber via low-pressure stabilization and bio-based precursors, and working with Saint-Gobain to commercialize oxide ceramic fibers for CMC.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreLingrove plant-based ekoa composite featured in Hyundai Palisade concept vehicle

Carbon-neutral biocomposite enables interactive doorspear with look and feel of wood while protecting trees, enabling transparency and capacitive touch for futuretech.

Read MoreRead Next

Mercedes-AMG GT4 race cars now equipped with Bcomp natural fiber composite bumpers

Bcomp works with engineering specialist HWA to phase in natural fiber bumpers, replacing carbon fiber versions. Analyses report a 90% reduction in material emissions and thermal energy recovery potential.

Read MoreBMW Group invests in Bcomp for high-performance natural fiber components

Collaborative partnership in motorsport moves to the next level for the use of renewable raw materials for future vehicle model components, and joint R&D materials work for production vehicles is underway.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More