Closed Mould Alliance to deliver sustainable resources, practices to composite molding

U.K. companies Alan Harper Composites, Ilium and Tower Composites collectively contribute expertise and solutions to reduce waste, improve efficiency and enhance the quality of composite parts.

Alan Harper Composites (Saltash, U.K.), Ilium Composites (Hidd, Bahrain) and Tower Composites (Tamworth, U.K.) have formed the Closed Mould Alliance, which aims to become a leading resource for composites manufacturers seeking to adopt innovative closed molding processes that deliver environmental, economic and operational benefits. By leveraging its partners’ collective expertise and advanced technologies, the Alliance will drive sustainable practices within the composites industry.

Alan Harper Composites specializes in reusable silicone technology for composite molding. With more than 15 years of experience, the company offers an extensive range of products, including molding supplies, silicone spray machinery, high-quality platinum cure silicone and training. The company is known for its custom-designed silicone membranes, which replace traditional vacuum bags or B counter molds. While particularly appealing to vacuum infusion molders, reusable silicone technology also offers significant benefits for hand lamination operators and other closed molding practices such as RTM and LRTM.

In a recent survey, 72% of participants cited efficiency and time savings as the primary reasons for their interest in the reusable process. Moreover, the technology has the ability to eliminate single-use plastics and reduce resin consumption, contributing to sustainability.

Tower Composites is a technical multi-market molder specializing in glass fiber composite molding parts for automotive, marine and construction. The company has integrated advanced reusable vacuum tooling systems that streamline production processes, minimize waste and enhance product quality.

Tower Composites has the ability to deliver customized solutions tailored to specific industry requirements, and is deeply committed to sustainability in its operations. Adopting reusable vacuum tooling systems has minimized the excess material often associated with traditional RTM and LRTM processes.

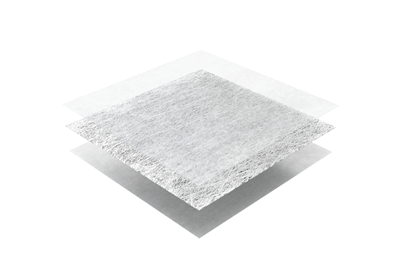

Ilium Composites manufactures and distributes high-quality fiberglass reinforcements using distinctive process technology. Its state-of-the-art manufacturing capabilities and mechanical binding system produce optimized resin flow and surface finish. Ilium’s stitch-free and chemical binder-free technology reduces time and costs while ensuring high-quality finished parts and the reduction of volatile organic compounds (VOCs). Moreover, flagship products, including the FLEXmat and ULTImat series, are designed to improve composite parts’ mechanical properties and surface finish, making them ideal for applications in construction, automotive, and marine industries.

Together, the Closed Mould Alliance is passionate about improving and promoting sustainable practices within the composites industry. Each partner contributes expertise and solutions that collectively reduce waste, improve efficiency and enhance the quality of composite parts. The Alliance’s technologies align with several Sustainable Development Goals:

- Immediate waste reduction: Using reusable silicone membranes reduces the consumption of single-use consumable materials like plastic film, peel ply and resin-locked flow mesh. For example, a single silicone membrane can replace 1,000 instances of single-use plastics.

- Enhanced part quality: Improved material consolidation and reduced resin use result in parts with a 10-30% lower material contribution. This reduction not only conserves resources but also facilitates easier end-of-life disposal.

- Lower carbon footprint: Innovations contribute to more sustainable manufacturing practices by reducing waste and improving production efficiency.

- Future development and innovations: Advancements in reusable silicone technology, such as the introduction of the Morph and Micro-Morph resin runners, integrate flow paths behind the reusable membrane molding surface.

- Industry applications and customization: Each project begins with thoroughly assessing the client’s molding setup and material requirements. The Alliance’s technical team provides bespoke support to ensure successful implementation and ongoing system optimization.

The Closed Mould Alliance represents a collaboration meant to redefine the composites manufacturing landscape.

Read Next

Ilium FLEXmat fiberglass is suitable for pultrusion processes

Latest long chopped glass fiber reinforcement technology enables high temperature exposure, material stretching and chemical resistance, making it a safer cleaner option for pultrusion manufacturing.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreGuidance for the thermoforming process

A briefing on some of the common foam core material types, forming methods and tooling requirements.

Read More