Composites Integration evaluates fiber, resin systems to reduce environmental impact of composites

Collaboration with the School of Engineering at the University of Plymouth looks at the effect of pre-processing and post-processing techniques on low-carbon materials.

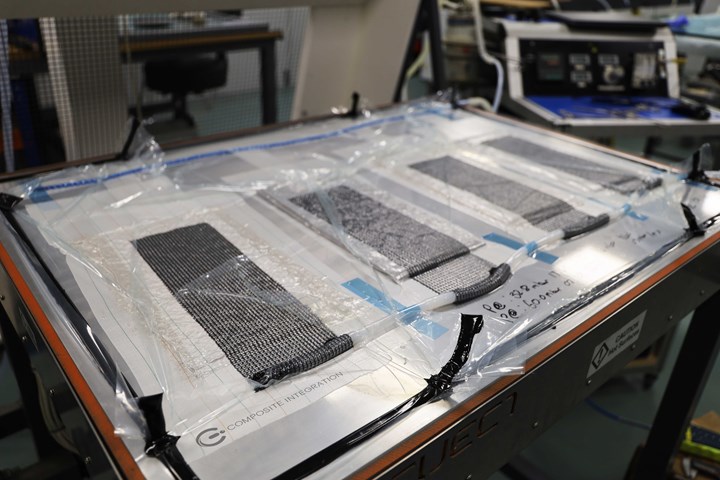

Composite Integration evaluates a range of natural, renewable and recyclable fiber and resin systems. Photo Credit: Composites Integration

As part of Composite Integration’s (Saltash, U.K.) long-term “Clean Composites” research and technology strategy, the company has placed an emphasis on understanding materials which can reduce the environmental impact of composite structures and components. In particular, the company is evaluating a range of natural/renewable/recyclable fiber and resin systems to ensure that it can provide comprehensive processing guidance to clients and partners.

The challenge of recycling traditional glass/carbon fiber polyester/epoxy composites are well known, says the company. The need exists to understand the processing requirements for a much wider range of fiber and resin systems, not only to ensure that Composite Integration’s Ciject RTM/VRTM injection equipment is capable of processing them, but also to understand the processing parameters to mold components successfully.

To support this work, Composite Integration is working with the School of Engineering at the University of Plymouth, an institution with a long pedigree of both research and undergraduate teaching in the field of composite materials. Placement Engineer, Joe Searle, is currently carrying out both detailed research into available materials as well as practical processing evaluation trials.

“The project focuses on identifying how we can produce high-quality ‘clean’ composites,” Searle says. “The project has looked at the effect of pre-processing and post-processing techniques on a wide variety of low carbon materials. Composite Integration has given me an opportunity to build my dissertation. Being able to use the experience and knowledge of the team at Composite Integration made researching the project significantly simpler.”

While the whole challenge of moving to a carbon-neutral manufacturing environment is a complex one, Composites Integration notes, it is clear that many small steps can be made to move in the right direction. By understanding how to work with lower impact materials through the “Clean Composites” strategy, Composite Integration aims to progress steadily toward this goal.

Related Content

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Watch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.