Coriolis Composites installs AFP machine at Sabanci University

C1 robot contributes to technology development at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) in Istanbul.

Share

Read Next

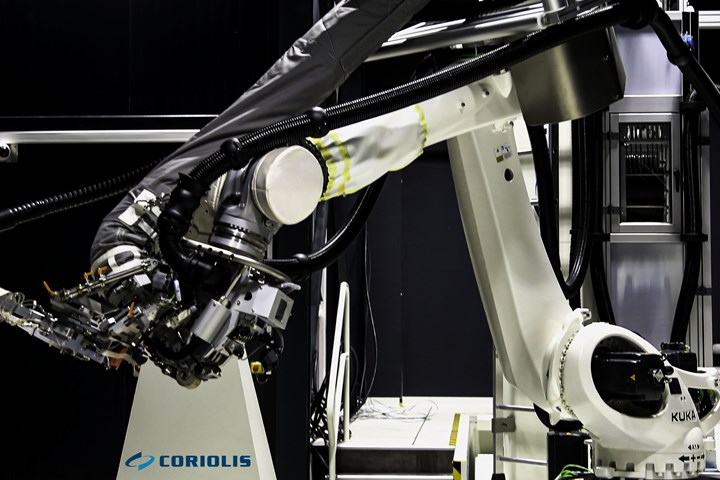

Coriolis Composites (Quéven, France) is pleased to announce the installation of its C1 automated fiber placement (AFP) system at the Integrated Manufacturing Technologies Research and Application Center (SU IMC) at Sabanci University (Istanbul, Turkey). This Coriolis C1 robot with 8-meter linear axis, a 6-ton headstock tail stock and six-kilowatt laser will be used in SU IMC’s technology development for applications in advanced thermoset and thermoplastic composites part manufacturing, especially for the aerospace and automotive industries. It can accommodate molds up to 6 meters long and 3 meters in diameter.

The C1 is a versatile AFP machine ideal for R&D applications using thermoset, dry fiber and thermoplastic materials. It features a compact head to lay up on concave and convex tools, as well as complex parts with a narrow radius. This flexibility is aided by its light robot base versus a heavy gantry, as well as the carbon fiber spool embedded in the head.

SU IMC is an industrial-scale R&D and open innovation center focused on advanced polymer composites and additive manufacturing (AM) technologies. According to Coriolis Composites, it provides value-added solutions and technology transfer for advanced manufacturing, including:

- Design and analysis

- Prototyping and product development

- Research and application

- Professional training

- Manufacturing and test services.

SU IMC is using the C1 system for material testing and manufacturing of demonstrators.

Related Content

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.