Joby Aviation advances toward FAA certification, highlights Toray prepreg and Coriolis AFP machines

Joby Aviation aims for FAA Part 135 certificate by end of 2022 and launch of commercial service by 2024 as it completes first production-intent aircraft from its pilot manufacturing facility; composites play a key role.

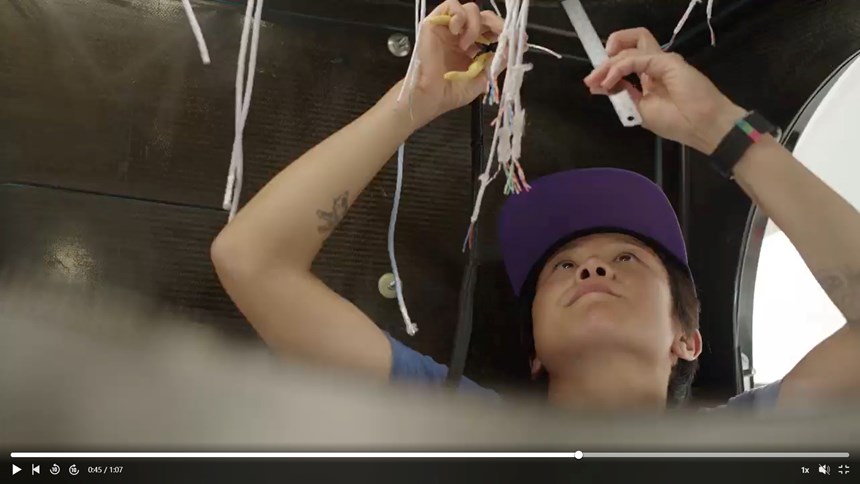

A Coriolis Composites automated fiber placement (AFP) machine shown here in a composites lab at Joby Aviation’s facility in Marina, California. Photo Credit: John Kaemmerling, Joby Aviation, see Toray press release

Joby Aviation (Santa Cruz, Calif., U.S.) is a leader in the advanced air mobility (AAM) market. It is currently working toward two Federal Aviation Administration (FAA, Washington, D.C., U.S.) certifications simultaneously. One is its Part 135 air carrier certification, which will allow it to operate as an air taxi service in the U.S. It has begun the fourth of five stages in that process. The second is its S4 eVTOL (electric vertical takeoff and landing) aircraft type certification. For this, the FAA provided in 2020 a signed certification basis (G-1 issue paper at stage 4) which details the specific regulations and special conditions for the Joby S4 aircraft. Joby and the FAA are now close to completing the means for ensuring compliance to these regulations.

The company is listed by the Advanced Air Mobility Reality Index as the overall market leader as well as in funding. It is one of four AAM companies slated to reach entry into service (EIS) by 2024.

- Dec 2020 – Joby agrees to acquire Uber Elevate which allows it to use the Uber app for its aerial vehicle (air taxi) ride-hailing service, slated to launch in 2024.

- Aug 2021 – The company trades as “JOBY” on the New York Stock Exchange after its SPAC (special purpose acquisition company) merger with Reinvent Technology Partners led by LinkedIn co-founder Reid Hoffman and Zynga founder Mark Pincus.

- Feb 2022 – Japan’s largest airline, via ANA Holdings (Tokyo), and Toyota Motor Corporation (Toyota, Aichi, Japan) partner with Joby to establish aerial ride-sharing in Japan while SK Telecom (Seoul, South Korea) partners to establish aerial ride-sharing in South Korea.

When Joby Aviation (Santa Cruz, Calif., U.S.) and Toray Advanced Composites (Morgan Hill, Calif., U.S.) announced a long-term supply agreement in Dec 2020, for carbon fiber-reinforced prepreg, the advanced air mobility (AAM) aircraft manufacturer noted that “high performance composite materials are essential in making the Joby aircraft lightweight.” JoeBen Bevirt, Joby Aviation founder and CEO said, “Toray’s prepreg carbon fiber systems provide unparalleled specific strength and toughness, which have enabled Joby to develop aircraft with unprecedented capabilities.”

Vacuum bag materials for curing prepreg parts in the background and CFRP propeller blade in foreground at right. Photo Credit: Joby Aviation’s LinkedIn post This is Joby

The Toray prepreg uses carbon fiber in a toughened epoxy matrix, according to Joby Aviation’s Feb 2022 press release, which announced the company had completed its first series of conformity tests for the S4 airframe at Toray’s Morgan Hills, California facility, observed and documented by an on-site FAA Designated Engineering Representative (DER). The company’s first FAA conformity inspections began in November 2021 with an FAA designee on site. “The focus of the inspection was a simple composite panel,” said Joby’s executive chairman, Paul Sciarra, “but its properties are representative of the entire airframe structure. The FAA’s inspection was checking that Joby is delivering its composite laminates according to the required aviation standards. “This marks a really important step towards design and production maturity for Joby and is another goal [we have] delivered on schedule,” said Sciarra. He also said that Joby continued to make rapid progress towards establishing initial production at its facilities in California.

Coriolis Composites AFP machines

Joby’s Nov 2021 shareholder conference call, Sciarra said that the three main goal for Joby were (1) certify the aircraft, (2) scale manufacturing and (3) prepare for commercial operations. Regarding certification, Sciarra said that Joby had begun testing individual parts and systems for its production aircraft, including tail spar load testing, battery drop testing, lightning strike testing and cabin/canopy bird-strike testing.

“Progress was similarly made at our site in Marina, [California] where we installed a second AFP, or automated fiber placement machine,” added Sciarra. Both of Joby’s AFP machines are from Coriolis Composites (Quéven, France), the first arrived in November 2019 and the second in June 2020. “We also built a rotating positioner that allows us to deliver increasingly complex parts from our carbon fiber layup process, as well as producing representative components for our production aircraft,” said Sciarra. “With the installation of our second AFP machine, we now believe we have sufficient capacity to support pilot plant volumes for our aircraft.”

Air Carrier Certification

In the same Nov 2021 call, Sciarra said that Joby had taken the first step toward achieving its Part 135 air carrier certification from the FAA, required to fly passengers for revenue across the U.S. “It’s a five-stage process,” he said, adding that the company had entered stage one in July and stage two of that process just prior to the call in November. “We expect that we’ll have the full certification in place by the end of 2022,” he concluded.

In the Q&A session at the end of the 3rd quarter 2021 conference call, Sciarra noted Joby’s strategy of controlling more of the design and development of the components that go into its first AAM aircraft. “It allows us, we think, to create a more performant aircraft than might be possible with off-the-shelf components,” said Sciarra, “but also … by controlling more of that, both design and manufacturing in-house, we think that gives us greater confidence that we’re going to be able to really program manage the certification process successfully and drive to certification in the timeframes that we outlined.”

Sciarra noted that Joby Aviation employs more than 1,000 people [1,124 as of Feb 2022 per Q4 2021 shareholder update referenced below] and almost 80% of those are working on the first aircraft certification and development.

The images in the slideshow below are from Joby Aviation’s LinkedIn posts This is Joby and Joby increases flight test capacity.

Composites at Joby aviation

Manufacturing and Q4 2021 update

Manufacturing progress

Joby completed its 125,000 square-foot of manufacturing space in its pilot manufacturing facility.

In Joby’s Q4 2021 shareholder letter, the company noted it had completed the build-out of 125,000 square feet of manufacturing space and, in early 2022, began the manufacture of its first production intent aircraft in its pilot manufacturing facility.

The letter further detailed: “This aircraft is the first to be built at our pilot manufacturing facility in Marina, CA and will benefit from our investment in advanced production technologies, such as Automated Fiber Placement machines and additive processes. We expect to fly this aircraft before the end of 2022.”

Regarding full-scale production, the letter noted, “Investments in our

Phase I manufacturing facilities are not planned to begin in 2022, as we evaluate production locations.”

During the Q4 2021 shareholder update, Morgan Stanley asked how many test aircraft would be built. Sciarra answered that Joby plans to build a number of aircraft in 2022-2023, but not all will for flight test, and that final number has not been finalized. At the same time, Joby wants to exercise its manufacturing muscle so that it is prepared to ramp production when necessary.

Related Content

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More