DLR project demonstrates hybrid AM process for composites

Latest DLR development in 3D printing combines additive extrusion technologies and AFP to present a new approach for manufacturing complex thermoplastic composite structures.

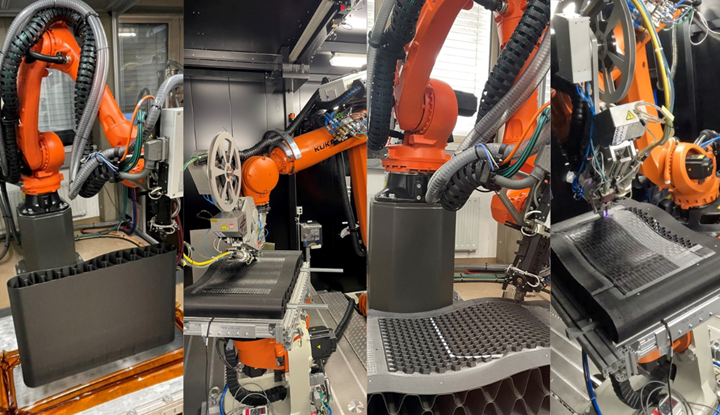

3D printing of complex tooling (far left), AFP in printed tools (left), overprinting of AFP laminate (right) and AFP on printed core (far right). Photo Credit: DLR

The DLR Institute of Structures and Design (DLR, Stuttgart, Germany) develops design strategies and the associated manufacturing technologies for the production of innovative, high-performance structures in aerospace applications. An important tool for the implementation of modern structural concepts is the additive manufacture (AM) of thermoplastic composites. To fully exploit the potential of these technologies, DLR is developing a hybrid manufacturing process combining additive extrusion technologies (3D printing) and automated fiber placement (AFP).

According to the company, this hybrid process combines the flexibility of 3D printing with the performance of AFP laminates and enables the production of composite components that are not feasible with other composites manufacturing processes. Possible applications include the production of multifunctional primary structures using functional materials, load-optimized sandwich structures with arbitrary curvature or individually stiffened shell structures.

In a current project, the full additive manufacturing of sandwich structures is demonstrated. In four manufacturing steps, the tooling, the two facesheets and the core are built up additively. The joining between the facesheets and the core takes place in-situ during the 3D printing or AFP processes, which ensures a single-variety component without downstream joining steps. To enable use in primary structures, only high-performance thermoplastics are used. In the demonstrator presented, the cover layers are deposited from carbon fiber-reinforced low-melt polyaryletherketone (CF/LMPAEK) unidirectional (UD) tapes. The overprinting is done with short fiber-reinforced polyetheretherketone (PEEK) in a robotic fused granular fabrication (FGF) process.

Watch a video of the hybrid process here.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Heat mapping simulation to improve AFP parts

An optical model developed for Coriolis Composites’ SimuReal AFP process simulation software enables verification of energy distributions during AFP to better define heating laws.

.jpg;maxWidth=300;quality=90)