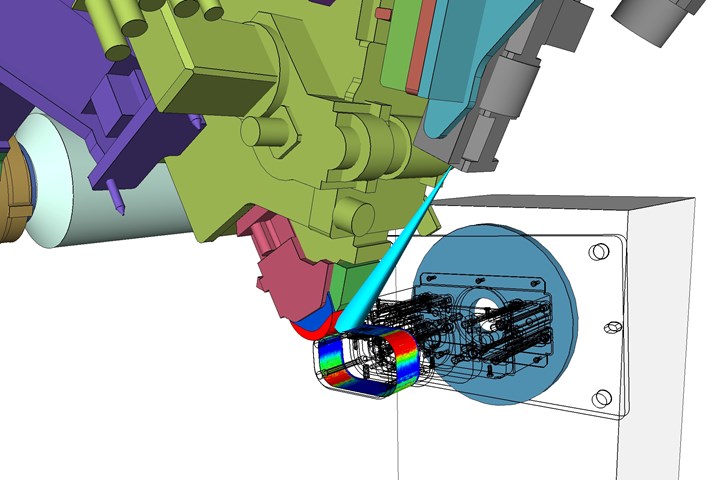

Figure 1. SimuReal simulation with heat mapping. Heat mapping is integrated into Coriolis Composites’ SimuReal software, correcting for IR camera incidence angle (IR camera seen at far top right) to identify nonhomogeneities and critical areas via a color heat mapping on the thermoplastic composite AFP part (multicolored rectangular part above) using laser heating (turquoise cone). Photo Credit, all images: Coriolis Composites

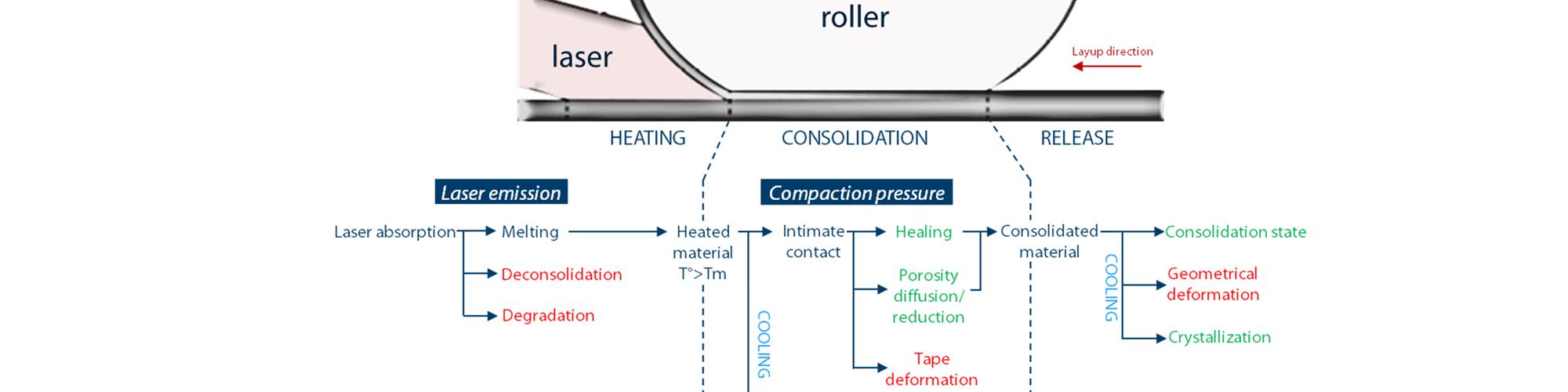

Image above article title: Process phenomena during AFP of thermoplastic composites using laser heating.

Automated fiber placement (AFP) is a highly efficient process that can be used to produce thermoplastic matrix composite parts. This process involves heating, compaction and cooling steps that must be understood and controlled to achieve optimal manufacture of structural parts. Coriolis Composites (Quéven, France) supplies AFP systems and works with its customers to simulate and optimize the AFP process and parts produced using the in-house developed CADFiber, CATFiber and SimuReal software tools.

CADFiber and CATFiber enable laminate stacking and toolpath design integrated with finite element analysis (FEA) and machine simulation (see “Optimizing AFP for complex-cored CFRP fuselage”). SimuReal then validates these laminate and toolpath designs using algorithms that approximate, as close as possible, the Siemens AFP machine controller and actual machine parameters with accurate speed changes through a virtual controller and digital twin model. This minimizes the need for dry runs and accelerates the transition from prototype to production.

A customer was experiencing issues with a particular part’s performance, which made the part more susceptible to failure. Coriolis explored the issue and found it was caused by AFP processing parameters that created temperature spikes in the laminate as a result of the part’s geometry. The Coriolis team believed this issue could be corrected by an improved ability to accurately measure the heated surface of the part during process simulation and parameter optimization. To achieve this, Coriolis developed a heat mapping numerical function in its SimuReal software to better predict heat distribution in AFP parts.

AFP process parameters

For thermoplastic composite tapes, AFP systems typically use a laser for heating, which provides high energy density for reaching the temperatures required to melt the polymers and efficient control during the process for reliable, repeatable production of high-quality parts1. However, temperature distribution in the AFP layup can be altered by process parameters including laser power, layup speed and compaction force2,3.

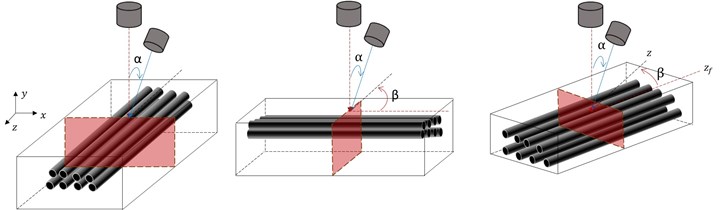

The geometric configuration of the laser and of the temperature measurement device — a compact infrared (IR) camera mounted on the AFP robot arm — also need to be considered and optimized to properly control the heat flux distribution at the nip point where the incoming tape is laid onto the substrate (Fig. 1). In several experiments, Coriolis measured the influence of the IR camera incident angle on the measured temperature at the nip point. From the results, Coriolis developed a relationship for the deviation in the measured versus predicted temperature (during simulation and parameter optimization) based on the IR camera incident angle from 0° to 90° as well as the orientation of the fiber in the layup substrate (Fig. 2), which also has an effect.

Figure 2. Factors affecting temperature measurement. Coriolis performed experiments to understand how changes in the incidence angle (α) between the IR camera and substrate as well as the fiber orientation (β) in the substrate affect the deviation between the predicted temperature in the layup during simulation and parameter optimization, and the measured temperature in the layup during the actual AFP process.

Heat mapping

A correcting factor was developed to account for this deviation between measured versus predicted temperature, and then applied to determine the actual temperature at the nip point during the layup process. From the above observations, and using geometrical analysis, Coriolis developed an optical model that enables a heat mapping function. This was then integrated into the company’s SimuReal AFP process simulation software.

The optical model is based on ray intersection techniques, which are mathematical models for tracing light rays through physical elements and media in order to analyze their interactions and behaviors. This optical model then enables verification of energy distributions during AFP and assists AFP programmers to better define heating laws — i.e., the mathematical function relating laser power and layup speed — as well as to identify overexposed areas and improve the homogeneity of heating.

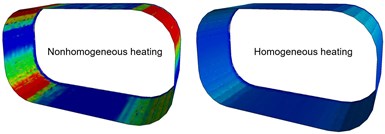

This optical model within SimuReal is a digital tool that prevents heating issues for any AFP part by predicting shadow areas and nonhomogeneous heating to correctly identify critical zones using a color map of heating/power distribution. This then enables the programmer to more accurately optimize the AFP process for part production, including modifications such as the ratio of laser power/layup speed.

Reduced risk of part failure

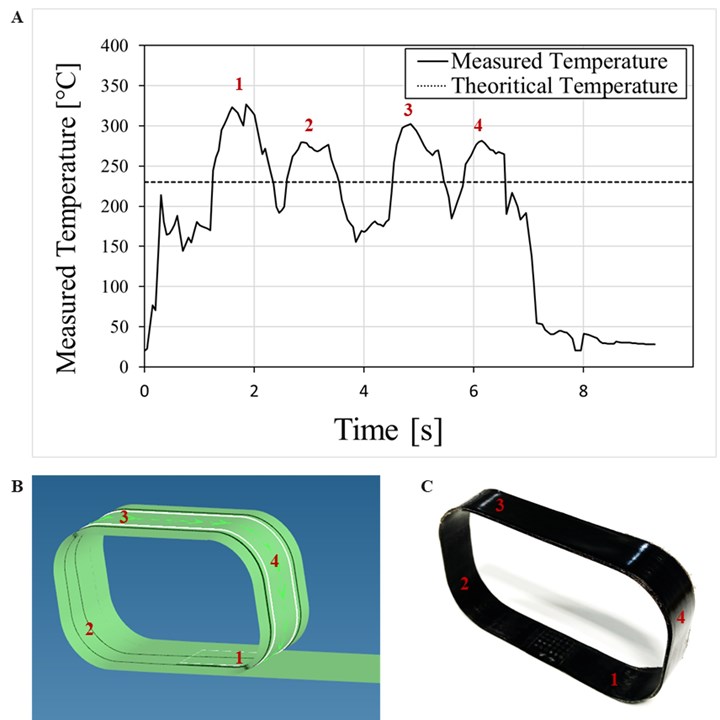

Figure 3. Correcting nonhomogeneous heating

This figure from reference [4] shows temperature spikes during layup of the customer part (top, A). These can be seen in the corners of the part in the heat mapping simulation at bottom, which was used to correct the necessary AFP process parameters to improve heat homogeneity during the part layup.

Coriolis applied this digital tool to the part discussed above. The simulation heat mapping showed nonhomogeneous heating with four critical regions in the corners of the part (Fig. 1 and 3). In these regions, the mean temperature reached 251°C ±46°C during layup, compared to the theoretical homogeneous temperature of 230°C (Fig. 3).

The color mapping showed that adjustment of the heat configuration in the corners would mitigate changes versus the flat regions of the part, and thus produce the desired homogenous heating. Several process parameters were identified as causing the heat heterogeneity: the IR camera incident angle, the laser beam angle, the heat exposure time and the layup speed. The incident angle of the IR camera and the angle of the laser heating changed during AFP layup in the corners, as did the distance between the optics and the surface. This impacted the energy absorbed by the material and the temperature measurement of the IR camera. This then led to significant differences in the temperature recorded at these regions and heat homogeneity over the full part.

Coriolis worked to optimize these parameters, which were resolved through successive iterations. Using this method, Coriolis was able to correct the AFP process and achieve heat homogeneity during part layup which then increased part stability and quality.

References

[1] Weiler, T., Emonts, M., Wollenburg, L., & Janssen, H. (2018). “Transient thermal analysis of laser-assisted thermoplastic tape placement at high process speeds by use of analytical solutions.” Journal of Thermoplastic Composite Materials, 31(3), 311-338.

[2] Grouve, W. (2012). “Weld strength of laser-assisted tape-placed thermoplastic composites.” University of Twente.

[3] Yassin, K., & Hojjati, M. (2018). “Processing of thermoplastic matrix composites through automated fiber placement and tape laying methods: A review.” Journal of Thermoplastic Composite Materials, 31(12), 1676-1725.

[4] Réquilé, S., et al. (2022). “Automated fiber placement of thermoplastic material: Towards an innovative way of controlling temperature homogeneity.” Conference paper: ITHEC 2022, Bremen, Germany.

About the Author

Samuel Réquilé

Samuel Réquilé holds a Ph.D. in biocomposite materials from the University of South Brittany, France. His focus is on innovation and development topics for composite applications. He is currently working as an R&D project engineer at Coriolis Composites and on developments for the AFP processing of thermoplastic materials. His main activities include the improvement of the reliability of AFP parameters from a material and machine standpoint. He is also focused on the thermoplastic composites technical roadmap through the management of development and customer projects.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreSTUNNING project completes lower half of MFFD

Clean Sky project has delivered the 8 × 4 meter welded aerostructure component, aided by advanced thermoplastic composite technologies and smart robotics.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More