EconCore, Flaxco reveal flax fiber-reinforced thermoplastic honeycomb panels

Natural fiber sandwich panels are expected to replace those made from glass and carbon fiber, offering enhanced rigidity and sustainability for applications in automotive and sporting good markets.

Share

Read Next

Photo Credit, all images: EconCore

EconCore (Leuven, Belgium), known for its honeycomb sandwich production, has collaborated with partner Flaxco (Roeselare, Belgium) to develop and manufacture a novel thermoplastic honeycomb sandwich panel.

Flaxco established itself in the early 1850s specializing in flax fiber weaving used in applications ranging from clothing to upholstery and decoration. This has evolved into manufacturing flax fibers for the composites industry, typically found in semi-finished products such as sandwich panels.

In 2020, Flaxco approached EconCore suggesting the combination of thermoplastic honeycomb technology with Flaxco’s flax fiber. EconCore says the polypropylene honeycomb material it produces offers a high-performance-to-weight ratio along with efficient energy absorption, all achieved through the material’s synonymous honeycomb-shaped hollow cells which support sandwich sheets to provide levels of high rigidity with minimal weight. Pioneering the use of flax with honeycomb technology, the partnership sees Flaxco’s flax fabric composite skins combined with EconCore polypropylene core to produce sandwich panels.

To generate a high level of stiffness, sandwich cores require surface layers, like the neatly woven layers that Flaxco has the means to create. Once developed, EconCore says the panels can be thermoformed — typically through short cycle compression molding — thanks to their thermoplastic properties.

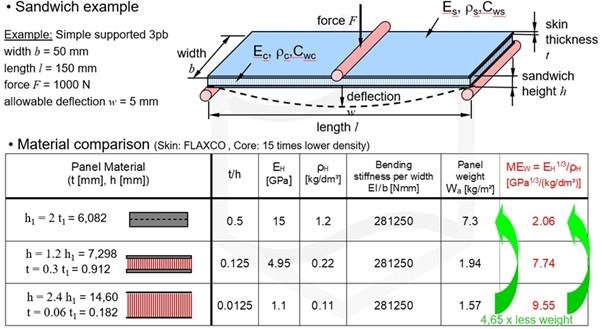

Achieving a product with well-balanced characteristics required the use of 0.5-1-millimeter-thick prepregs. Optimizing its flax technology with the polypropylene honeycomb core enabled Flaxco to achieve much higher levels of rigidity. The table below describes the bending performance of a sandwich panel with flax composite skins.

In addition to being a 100% recyclable, natural fiber that produces lower CO2 levels than competing materials including glass and carbon fibers, the Flaxco composite is expected to be the material of choice in a number of applications, especially those requiring dimensional stability. This includes automotive and even the sports industry, Flaxco notes.

“For new product developments sustainable materials have become a key requirement. Within the automotive industry in particular, suppliers seek sustainable materials which lower their CO2 footprint,” says Dr. Jochen Pflug, EconCore CEO. “Flaxco’s natural flax fiber polypropylene composites are an ideal combination with our polypropylene honeycomb cores to achieve a sustainable material that retains high levels of performance. The production costs of thick monolithic laminates are high because many layers need to be combined. Our honeycombs increase the stiffness and strength but require only a minimal amount of material in two thin surface layers.”

One factor that has greatly benefited the partnership between Flaxco and EconCore is the locations of both company’s facilities in Belgium, which is said to enable a local supply chain.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.