EconCore

Ambachtenlaan 25

Leuven, 3001 BE

32 16 381060

info@econcore.com

econcore.com

About EconCore

Offers economical cores and panels for cost-optimized lightweight sandwich solutions; patented technologies for automated continuous production of paper honeycombs (TorHex) and thermoplastic honeycombs (ThermHex); integration into continuous inline production of sandwich panels/parts; product/process development services for specific applications.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

EconCore Supplies the Following Products

- Consulting, materials

- Consulting, process development

- Continuous laminating

- Continuous laminating machines

- Honeycomb structures

- Honeycomb, other

- Honeycomb, thermoplastic

- Laminate panels, with core

Trade Names Offered by EconCore

Editorial, News, and Products

-

Composites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

-

Thermoplastic honeycomb, lightweight solar modules demonstrate sustainability

CAMX 2023: Together, EconCore and ThermHex are providing a first look at new product variations for additional lightweight opportunities, including high-performance thermoplastic cores and solar panels with a honeycomb structure.

-

EcoRudder project to develop thermoplastic composite aircraft rudder

Airbus, EconCore, Fraunhofer and the Technical University of Denmark will produce a potentially recyclable rudder from thermoplastic honeycomb sandwich composites.

-

EconCore, Solarge launch lightweight, sustainable solar panel

Netherlands-based EconCore and Solarge have collaborated to develop a composite solar panel that offers weight savings of up to 65%.

-

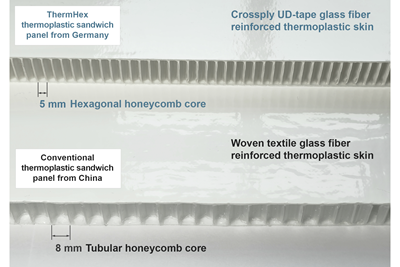

ThermHex Waben highlights thermoplastic honeycomb panels

Economically produced composite sandwich panels are sustainable while maintaining high mechanical performance and surface quality, driving them into new market applications.

-

Global experts present latest developments at Composite Sandwich Conference in May

The CSC 2022 conference, jointly organized by Thermhex and Fraunhofer IMWS, enabled a productive exchange of information about cost-efficient composite sandwich structures and automated processing methods.

-

Formula Electric Belgium's Titan race car features EconCore rPET honeycomb

Front wings and undertray comprise the honeycomb core material, the latter reducing wing weight by 26% compared to the previous year, and able to withstand forces 1,000 times its own weight.

-

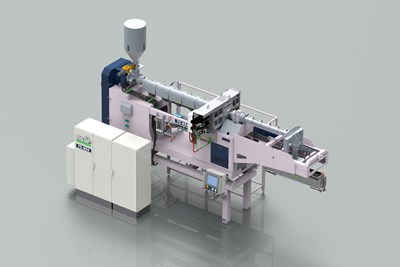

EconCore, ThermHex Waben optimize honeycomb core production

An investment in additional MEAF 75-H34 extruders reduce energy consumption in honeycomb production by up to 65% and double capacity.

-

EconCore, Flaxco reveal flax fiber-reinforced thermoplastic honeycomb panels

Natural fiber sandwich panels are expected to replace those made from glass and carbon fiber, offering enhanced rigidity and sustainability for applications in automotive and sporting good markets.

-

Basaltex reveals basalt fiber milestone for use in rail carriage interiors

Testing and development of basalt fiber, bioresin and rPET combo achieves rigidity, fire resistance and lightweight properties that meet railway application standards.

-

ThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products

Targeting recycled and high-performance thermoplastic options, automated R&D lines increase volume and speed for honeycomb, sandwich panel and finished part production.

-

EconCore thermoplastic honeycomb cores deliver high-heat performance, facilitates recyclability

Honeycomb cores incorporate Sabic NORYL GTX resin for improved dimensional stability, lower water absorption and demonstration of thermoset composite skin compatibility.

-

EconCore, Renolit honeycomb sandwich panel developments explore diverse applications

EconCore lightweight honeycomb enables Renolit Gorcell product line to overcome technical challenges and push the application spectrum for automotive and other markets like furniture and garden.

-

ThermHex reports a €1 million capital increase

The business growth follows new investments to further optimize and expand ThermHex’s digitalization of its honeycomb core production processes.

-

People in Composites: February 2021

Teijin Ltd., CSP, EconCore, Metyx, Zetec, Workhorse and more announce new hires in the composites industry.

-

Two major automotive OEM contracts secured for EconCore honeycomb core technology

Mexican manufacturer Fynotej will supply OEMs with the lightweight and sustainable Fynocore — licensed under EconCore — for automotive application.

-

AZL, EconCore, Audi partner to develop composite battery casings

A new project aims to identify potential opportunities and challenges for composite materials within the electric vehicle battery enclosure market.

-

EconCore announces partnership for sustainable car concept project

Dubbed Luca, the concept car incorporates EconCore’s recycled PET honeycomb cores, as well as other waste materials including horse hair, coconut fiber, flax and plastic bottles.

-

AZL begins multi-material battery casing project for electromobility

The eight-month joint development project will begin with a concept study for the final design and manufacture of the prototype. Interested companies can initiate participation until October 22, 2020.

-

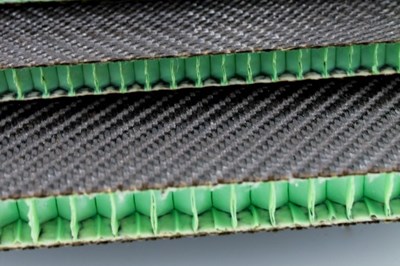

EconCore, Toray and Bostik collaborate on FST-qualified thermoplastic honeycomb panels

Developed for mass transportation applications, including aircraft interiors, the material improves upon the cost, sustainability and versatility of conventional sandwich layup.

-

Polypropylene honeycomb lightens, strengthens automotive panels

Polypropylene honeycomb cores from ThermHex are used by Brazilian OEM DPA Moldados to make the trunk floor of the Hyundai Creta ix25.

-

EconCore licenses recycled PET honeycomb core technology

The company’s rPET honeycomb core is made from more than 95% recycled PET and is reported to outperform PP honeycomb cores.

-

EconCore evolves thermoplastic, recycled honeycomb core materials

EconCore’s latest research is focused on high-performance honeycombs and recycled polyethylene terephthalate (RPET) honeycomb technology.

-

Low & Bonar licenses EconCore’s thermoplastic honeycomb technology

Using EconCore’s honeycomb technology, Low & Bonar has developed a lightweight flooring underlay product designed with high acoustic properties.

-

Automotive interior Tier 1 supplier signs license for EconCore technology

Japanese manufacturer Kokobukiya Fronte will use EconCore’s production technology to produce honeycomb materials under brand name M-Light.

-

EconCore thermoplastic honeycomb panel production technology

EconCore’s ThermHex honeycomb technology converts thermoplastics to high-performance, lightweight honeycomb core structures and, combined with inline lamination of skins, produces lightweight sandwich panels.

-

EconCore breaking new ground with high-performance core materials

EconCore’s new ThermHex high-performance thermoplastics (HPT) honeycomb materials are well suited for applications requiring lightweight solutions but still needing to meet heat resistance and fire-smoke-toxicity (FST) requirements.

-

Covestro and EconCore collaborate on FST-optimized honeycomb core and panels

The collaboration aims to optimize the FST performance of honeycomb panels for public transportation applications, including railway and aerospace.

-

EconCore licenses Fynotej for NA automotive applications and advances into high-performance thermoplastics (HPT)

Branded Fynocore, these panels have a PP honeycomb core with skins – thermally bonded in-line – in either solid PP sheet or including a non-woven surface finish.

-

EconCore partners with MEAF on continuous thermoplastic honeycomb cores

EconCore (Leuven, Belgium) is making progress in development of new all-thermoplastics continuous honeycomb cores.

-

Simplifying the solar panel with composites

Replacing glass and aluminum with a polymer/cored polymer composite laminate ups panel durability at reduced weight.

-

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.