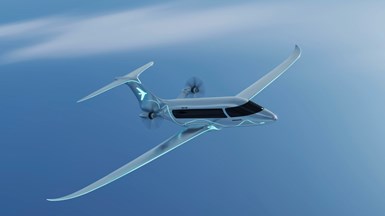

Embraer unveils four Energia concept aircraft for net-zero aviation by 2050

Aircraft being developed span 9 to 50 seats and electric, hydrogen fuel cell, dual-fuel gas turbine and hybrid-electric propulsion.

On Nov. 8, Embraer (São José dos Campos, São Paulo, Brazil), the world’s third largest aircraft manufacturer, announced the Energia family of concept aircraft that it is exploring to help the industry achieve its goal of net-zero carbon emissions by 2050. The details of the Energia family — released to coincide with the COP26 climate gathering in Glasgow — were broadcast live via YouTube from Embraer’s manufacturing facility in São José dos Campos, Brazil.

The company has partnered with an international consortium of engineering universities, aeronautical research institutes and small- and medium-sized enterprises (SMEs) to better understand energy harvesting, storage, thermal management and their applications for sustainable aircraft propulsion.

The Energia family comprises four concept aircraft that incorporate different propulsion technologies: electric, hydrogen fuel cell, dual fuel gas turbine and hybrid-electric. With various combinations of range and technology, Embraer says it sees a potential market for some 4,000 airplanes.

Each aircraft is being evaluated for its technical and subsequent commercial viability.

As reported by Reuters reporters Gabriel Araujo and Tim Hepher, the two nine-seaters could be flown by a single pilot. The 19-seater is powered by hydrogen-based fuel cells and the 35-50-seater is designed to use hydrogen on short routes, backed up by sustainable aviation fuel (SAF) for extra range and emergency reserves.

As reported by Reuters, these designs are the result of work kept under wraps for two years and would address a gap between the new eVTOL or flying-taxi industry and 50-seater turboprops or small jets. Embraer believes that small regional planes will be the first to embrace breakthrough technologies like hydrogen, ahead of the larger narrow-body commercial jetliners.

“It’s a segment where we believe a lot of opportunities lie ahead,” Arjan Meijer, chief executive of Embraer Commercial Aviation, told Reuters in an interview.

Embraer said it was open to partnerships to develop the planes, which would be competing in what has historically been a volatile niche of the aircraft industry.

Reuters reports Embraer Marketing Vice President Rodrigo Silva e Souza as saying the rejigging of global supply chains and a trend towards working remotely would put greater emphasis on flying short distances.

Meanwhile, Embraer is proceeding with plans for smaller eVTOL aircraft through a spin-off called Eve Urban Air Mobility. The fully-electric, zero-emissions vertical take off and landing vehicle is being developed to enter service in 2026.

Embraer also continues to seek financial or industrial partners to help launch a proposed new turboprop, Meijer told Reuters. It has hinted at a possible decision early next year.

“We see our role as a developer of novel technologies to help the industry achieve its sustainability targets,” explained Luis Carlos Affonso, Embraer’s senior VP of engineering, technology and corporate strategy. “There’s no easy or single solution in getting to net zero. New technologies and their supporting infrastructure will come online over time. We’re working right now to refine the first airplane concepts, the ones that can start reducing emissions sooner rather than later. Small aircraft are ideal on which to test and prove new propulsion technologies so that they can be scaled up to larger aircraft. That’s why our Energia family is such an important platform.”

“We will see a big transformation in our industry towards a more sustainable aviation,” added Meijer. “With 50 years of experience in developing, certifying and supporting regional aircraft, Embraer is in a unique position to make viable the introduction of new disruptive green technologies."

Although the Energia airplanes are still on the drawing board, Embraer has already made advances in reducing emissions from its aircraft. Within its family of E-Jets, Embraer has already tested drop-in sustainable aviation fuel (SAF), as well as mixes of sugarcane, camelina plant-derived fuel and fossil fuel. The company is targeting to have all Embraer aircraft SAF-compatible by 2030.

Last August, Embraer flew its Electric Demonstrator, a single-engine EMB-203 Ipanema, 100% powered by electricity. A full electric demonstrator flew this year and a hydrogen fuel cell demonstrator is planned for 2025.

For complete information about Embraer’s Sustainability in Action initiative and specifications for each Energia concept aircraft, go to https://www.embraercommercialaviation.com/sustainabilityinaction. Also see the detailed synopsis by Graham Warwick and Jens Flottau in Aviation Week.

Related Content

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreMicrowave heating for more sustainable carbon fiber

Skeptics say it won’t work — Osaka-based Microwave Chemical Co. says it already has — and continues to advance its simulation-based technology to slash energy use and emissions in manufacturing.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)