EMPHASIZING project investigates glass fiber upcycling

U.K. consortium aims is to develop a material from recycled glass fiber with mechanical properties superior to virgin glass but at a price point lower than carbon fiber.

A UK consortium led by B&M Longworth (Edgworth, U.K.), developer of the DEECOM recycling process, with partners from Ford Motor Co., Gestamp, Gen2Plank, EMS-Grivory, and academic partners from The Welding Institute (TWI) and Brunel University London (BUL), are engaged in the EMPHASIZING project partly funded by Innovate UK to investigate true upcycling of glass fiber to deliver a genuine viable material with high potential secondary use.

The consortium is particularly interested in the non-biodegradable glass fibers used in the development of wind blades, as they are believed to have been ignored in the concentration on recycling the known and commercially viable materials (wood, aluminum, carbon fiber) in the makeup of the blades. Moreover, the cost of virgin glass is relatively inexpensive — circa €2 per kilo. Thus, the material’s secondary use is currently limited and without a business case.

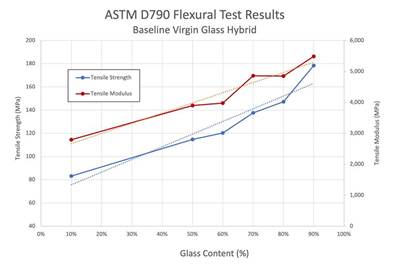

The aim of the U.K. project is to develop a material with mechanical properties superior to virgin glass but at a price point lower than carbon fiber, providing a viable, commercially acceptable material that can bridge the gap between glass and carbon fibers.

Graphene was selected as the sizing agent for the project due to its versatility and suitability to upscale glass fiber.

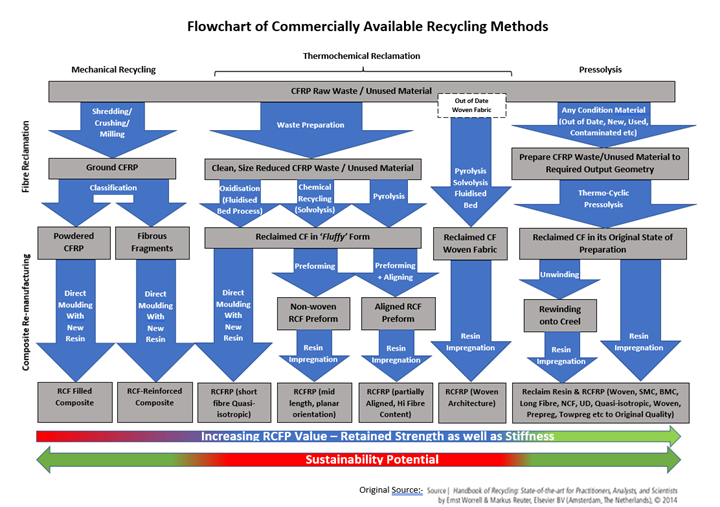

Each wind blade will be chopped to a size that is commercially acceptable to the secondary use and put through the “pressolysis” process developed and patented worldwide by B&M Longworth, also known as DEECOM. Previously used in the Innovate UK CHASSIS project, it has been proven to recover all of the material to the same standard as its virgin form — not just composite fibers, but any metallics, etc.. This process removes resin using superheated steam that undergoes compression and decompression cycles to strip the resin from the fiber. Unlike solvolysis or pyrolysis, pressolysis does not interact with the fiber in any way, thus leaving a pristine version of it behind. The resin is also recoverable during this process but is not the subject of this project, though it is being explored through separate R&D projects.

Crucially, the stripping of the resin from the fiber also removes its sizing which enables the upcycling of the fiber as the secondary process, and allow resizing later, as needed.

To upscale and improve the fiber’s mechanical properties, the sizing agent to be applied will be graphene. The project will determine the effects of graphene sizing on the glass fiber’s mechanical properties as well as the cost equation of making the material viable for commercial use. The belief among the consortium is that the mechanical properties will be around the mid-point of glass and carbon fiber with a price point more toward virgin glass fiber.

Graphene was selected as the sizing agent for the project due to its versatility and suitability to upscale glass fiber. Graphene, in isolation, is said to be a very expensive material to manufacture. However, the volume of graphene required compared to the material substrate is approximately 0.5%, thus making recycled glass affordable.

Carbon fibers recovered by pressolysis (top of bottom image) and glass fibers recovered by the same process (bottom of bottom image).

There are many ways of producing graphene, including chemical vapor deposition, flash Joule heating, laser-induced graphene and more. While the production method isn’t important for the purposes of this research project, the work packages undertaken will include a full lifecycle analysis (LCA), so the flash Joule heating method in particular is being considered. “Flash graphene” is generated by heating of any carbon element to 3,000°F via an electrical impulse. All of the non-carbon elements are “sublimed” out, leaving graphene as the only material left in the chamber. This process leaves the graphene in a non-stacked (turbostratic) state for ease of dispersion.

As well as determining the material characteristics of graphene-sized glass fiber, a suspension component will be made and tested against its metallic counterpart to assess its suitability for structural parts and to correlate against CAE predictions.

The final element of the project will be to understand the LCA for Scopes 1 and 2 — material production and manufacturing phase — as well as Scope 3 for the weight reduction of the component on the vehicle in the use phase. Scope 1 data will include the CO2 output from the pressolysis process to ensure the full emissions are taken into account.

Due to finish in October 2024, members of the EMPHASIZING project hope to ensure a known business case for using upcycled glass fiber.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreRead Next

University of Sydney develops recycling method for composite waste

With 840,000 tonnes of composites waste looming on the horizon, Australian researchers have discovered a recycling approach with increased material recovery and improved energy efficiency.

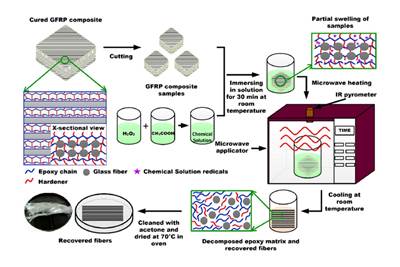

Read MoreIIT Mandi researchers use microwaves, eco-friendly chemicals to recover glass fibers

Development of a rapid, sustainable microwave-assisted chemical recycling process targets decommissioned wind turbine blades, promotes decreased landfill disposal.

Read MorePilot program turns EOL wind blades to liners for pipe infrastructure

TPI Composites, Tex-Tech and Carbon Rivers partner to process wind blades, pyrolyze the material and use the recovered glass fibers to give new life to damaged existing pipelines.

Read More

.jpg;maxWidth=300;quality=90)