FITS Air thermoplastic sandwich panels enable low-cost, low-weight, sustainable aircraft interiors

FITS Air and FITS Base sandwich panels provide alternative material avenues for aerospace and other industries, including low weight, low part production cost, thermoformability and recyclability.

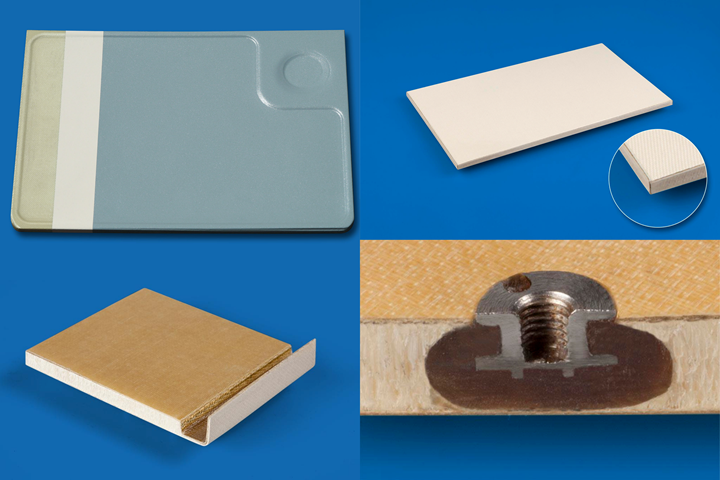

Product examples using FITS Air thermoplastic panels are shown above, from AC seat tables to box construction. Photo Credit, all images: FITS Technologies.

In the last 50 years there has been a significant shift in materials — such as the switch from aluminum to composites — used for exterior aircraft structures, a shift following the global trends in low weight, low cost and recyclability. However, when it comes to aircraft interiors, part manufacturing methods have often remained unchanged; Nomex honeycomb with fiber-reinforced phenolic facings, potting compound and aluminum extrusions, for example, are still the materials of choice and have been for many years.

An obvious alternative to eliminating these obsolete techniques would be a technology that offers part integration and thermoforming capabilities, which in turn could facilitate transition into an Industry 4.0 mindset — an option, says FITS Technology (Driebergen, The Netherlands) inventor and CEO, Martin de Groot, offered by the company’s Foamed In-situ Thermoformable Sandwich (FITS Air) technology.

FITS Air is produced in sheet form by in-situ foaming a thermoplastic polyetherimide (PEI) foamable (physical blowing agent) film between two fiber-reinforced PEI (supplied by SABIC, Riyadh, Saudi Arabia) facings via a press. The patented process creates a vertically oriented thermoplastic foam and bonds the fiber-reinforced thermoplastic facing to the foam in one step (see “Thermoformable Composite Panels, Part II”).

According to the company, the lack of an adhesive layer, a foam featuring vertically oriented cells, high compression strength and a structural orientation with no L- or W-direction ensures delivery of superior properties over current Nomex panels (see table below for comparison). Further, the use of PEI as the only thermoplastic material in core and facing fulfill all flammability and smoke-toxicity requirements.

|

Panel t = 10 mm* |

FITS Air panel** |

Nomex/phenol |

PEI foam/phenol |

|

Density core |

90 kg/m3 |

48 kg/m3 |

80 kg/m3 |

|

Compression strength/mod |

2.7/120 MPa |

1.9/145 MPa |

1.2/70 MPa |

|

Shear strength/mod |

1.2/19 MPa |

1.1/32(L dir.) MPa |

1/19 MPa |

|

Climbing drum peel strength |

90 |

45 |

60 |

|

Tensile strength/mod |

4 MPa |

2 MPa |

1.7 MPa |

|

Adhesive weight |

-- |

150 g/m2 |

150 g/m2 |

|

Panel weight |

2,440 g/m2 |

2,390 g/m2 |

2,680 g/m2 |

|

Tg |

210 °C |

105°C |

105°C |

|

Retention at 80 °C |

85 % |

65% |

75% |

|

* Facings: 2/2 US style 7781 glass fabric + 33% resin |

** t = 8 mm, same bending stiffness/strength as Nomex 10 mm in L-direction |

||

Notably, the fiber-reinforced thermoplastic facings and vertically oriented PEI foam core make FITS Air panels thermoformable, enabling opportunities in weight and cost savings. Further research has shown that the facings themselves can be manufactured in-house as a part of the manufacturing process, additionally lowering FITS Air panel production cost. The product is also entirely recyclable.

FITS Air is currently developed to technology readiness level (TRL) 6, with panels manufactured at a size of 1.28 meter x 1.48 meter with optimized mechanical properties.

FITS Technology provides product examples using this technology, including box constructions, floor panels, aircraft seat table, PSU panels and the lids of oxygen systems.

Box constructions using FITS Air panels reportedly result in slimmer parts with no added weight at the edges. Processing time using a dedicated thermoforming machine is two minutes/panel. Application areas include OSC, galleys, floor panels, toilet doors, etc. Weight savings of 200-500 kilograms/AC are expected depending of the type of AC, at a 10-50% lower cost.

A crude calculation indicates that all luggage bins (including the support structure) in Airbus (Toulouse, France) or Boeing (Chicago, Ill., U.S.) aircraft could be manufactured with approximately 10 dedicated automated thermoforming, insert and welding machines with a manufacturing time of 90 minutes/bin. This, says the company, can be achieved with minimum hand labor and no cure time; cost reduction up to 50% is feasible.

FITS Air’s homogenous properties also make floor panels a potential avenue. Tests have shown that impact levels demonstrate visual damage only, with a dent in the top layer of the impacted fiber-reinforced facing and the in-situ foam crushed just under the dent. Beneath the impacted facings, the foam is still completely intact. Further peeling of the facing — which FITS Technology says sometimes occur with Nomex floor panels — is not possible with the in-situ foamed core.

FITS Air is currently developed to technology readiness level (TRL) 6, with panels manufactured at a size of 1.28 meter x 1.48 meter with optimized mechanical properties. Although FITS Air is also patented, says the company, the business itself is still ripe for development and awaits proper uptake and commitment from the civil aerospace sector.

FITS Base

Alternately, FITS Base is a batch or continuously manufactured FITS sandwich panel based on polypropylene (PP), Nylon, polyamide (PA) or other low-cost polymers, which is foamed in-situ with chemical blowing agents. According to FITS Technology, the thermoformable sandwich panels are available for other markets, but without some of the physical characteristics required for aerospace, such as battery housings for battery electric vehicles (BEVs), motorhomes and cladding for houses.

FITS Base panels can be continuously manufactured via thermoplastic films, fibers, fabrics and foamable (extruded films with a chemical blowing agent) films, resulting in a panel with consolidated fiber-reinforced facings and an in-situ foamed core featuring vertically oriented foam cells. This means it is possible to continuously consolidate the fiber-reinforced thermoplastic facings, to foam the vertical cells and to create a complete bonding between core and facing all in one step. FITS Base is said to be well-suited for low-cost large series part production. Crush energy absorption tests with FITS Air panels have reportedly shown 50% higher crush energy absorption compared to round cell foam.

FITS Base is currently at TRL 3 and still requires low-cost fundamental research before up-scaling to batch and/or continuous manufacturing. Like FITS Air, this product is patented globally.

Related Content

Sustainable Infrastructure Systems creates fiber-reinforced post-consumer plastic structural panels

Australian composites manufacturer offers a scalable building solution, already established in a pedestrian bridge application, to tackle unprocessed soft plastics waste.

Read MoreCIDER project highlights rCF automotive door using Elium resin

European consortium develops novel processes, sustainable designs through three demonstrators to increase recycled carbon fiber use in transportation applications.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreAcciona to build wind blade recycling plant in Spain by 2025

Waste2Fiber facility will use a proprietary thermal method to separate wind blade materials for reuse and will have a processing capacity of 6,000 tons of material/year.

Read MoreRead Next

Move over honeycomb, thermoplastic sandwich is commercialized as DYNATECH

PEI foam core/skin sandwich panels claim to save up to 40 percent weight and 30 percent cost in rail and aircraft interiors vs. honeycomb.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;maxWidth=300;quality=90)