GKN Aerospace, SAMC, AVIC Supply sign JV agreement for advanced aerostructures

The strategic joint venture agreement supports GKN’s growth in the Chinese commercial aerospace market.

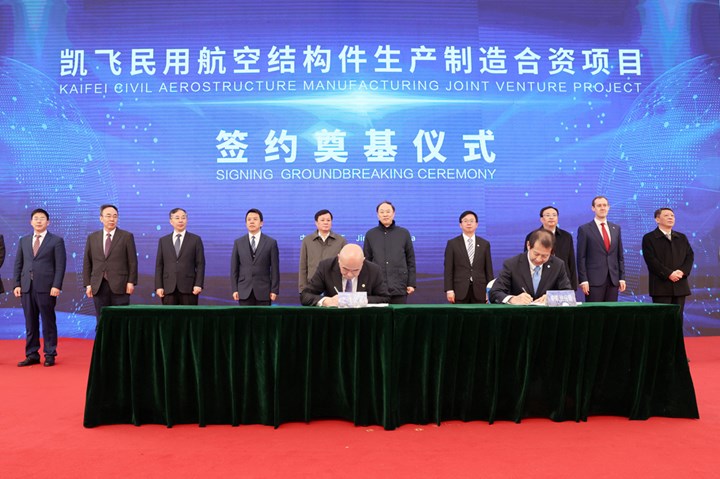

COMAC subsidiary SAMC, AVIC Supply and GKN Aerospace sign a strategic joint venture agreement to support Chinese commercial aerospace market. Photo Credit: GKN Aerospace

COMAC subsidiary SAMC (Shanghai Aircraft Manufacturing Company, Shanghai, China), AVIC Supply (Beijing, China) and GKN Aerospace (Redditch, U.K.) have signed a joint venture (JV) agreement for the manufacture of composite and metallic aerostructures in Jingjiang, China. This agreement represents a significant milestone in GKN Aerospace’s long-stated ambition to grow within the commercial aerospace market within China.

The state-of-the-art, 80,000-square-meter facility in Jingjiang will be GKN Aerospace’s first aerostructures JV in China, and will offer COMAC, AVIC and Western customers the opportunity to access an important local supply of advanced aerostructures in the country. The JV builds on COMAC, AVIC and GKN Aerospace’s proven track record in the global commercial aviation industry. Production is scheduled to begin in Q4 2021.

In addition to the JV facility, GKN Aerospace says it is in final preparations to open a separate 20,000-square-meter site in Jingjiang by April 2021, focusing on the manufacture of transparencies for the commercial market.

“The establishment of the first aerostructures JV and the upcoming opening of the transparencies facility in Jingjiang, China, are exciting milestones,” says John Pritchard, president Civil Aerospace at GKN Aerospace.

GKN Aerospace further reports that it has a strong three-continent footprint, supporting customers in the Americas, Europe and in Asia. In recent years, the company’s growth in Asia has included opening a new wiring systems plant in Pune, India, in 2019, as well as unveiling a new aeroengine repair and research plant in Johor, Malaysia, in October 2018. With two new sites in China, GKN Aerospace will be delivering aerostructures, wiring systems and transparencies for the commercial aerospace market from seven sites across China, India, Malaysia and Turkey.

Related Content

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.