Graphene Council awards verified graphene functionality to Mito Material Solutions

Verification encompassed proof of scale for three to five metric tons annually of Mito’s functionalized graphene material, E-GO, provides opportunities for introduction into more robust applications.

Specialty chemical company Mito Material Solutions (Indianapolis, Ind., U.S.), announces that The Graphene Council (New Bern, N.C., U.S.) has awarded it with the first Verified Functionalized Graphene status for Mito’s graphene additive, E-GO.

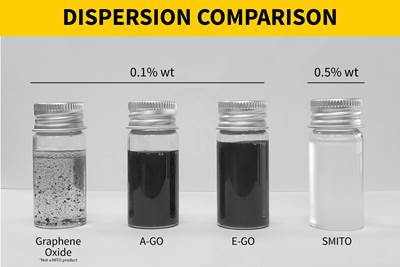

The patented technology platform is a process that can functionalize graphene in order to create hybrid additives with both chemical and physical bonding points. Mito’s products give fiber-reinforced composites and thermoplastics lab-verified improvements in strength, durability, flexibility, functionality and sustainability. Now, with this new verification status, Mito E-GO has also passed rigorous audits and third-party testing to ensure product consistency and quality.

“Through this process, we’ve proven that Mito does not just make graphene or graphene oxide, Mito truly functionalizes graphene with a polymer which is differentiated in the marketplace,” Haley Marie Keith, Mito CEO, says. “Thanks to the Graphene Council, Mito can now assure customers, with this third-party certification, that any E-GO material that they purchase is verified raw graphene material in our finished product as well as a functionalized polymer with graphene attached.”

“The Verified Functionalized Graphene status is a recognition that customers can rely upon that they are working with a competent and capable partner.”

Founded in 2013, The Graphene Council is reported to be the oldest and largest trade and professional association for the global graphene sector, serving the needs of graphene researchers, producers, application developers, end-users, regulators, standards bodies, national governments and other critical stakeholders. The Graphene Council connects more than 30,000 materials professionals and experts globally.

“Functionalization is a highly skilled process of taking graphene and enhancing its properties through targeted addition of other elements or processing the material. Mito Materials is a pioneering firm that specializes in this skillset and we congratulate them for successfully passing a rigorous in-person inspection of their facilities, processes and third-party testing of their materials,” Terrance Barkan, executive director, The Graphene Council, adds. “The Verified Functionalized Graphene status is a recognition that customers can rely upon that they are working with a competent and capable partner to supply functionalized graphene materials at commercial scale.”

The rigorous verification process included safety controls audit, technical audit, on-site lab evaluation and an on-site evaluation of the toll manufacturer, Monument Chemical (Brandenburg, Ken., U.S.). Independent third-party testing of both lab and production site materials using Mito’s own quality control processes was the final step in the process.

The verification encompassed proof of scale for three to five metric tons annually of Mito’s functionalized graphene material, E-GO. As E-GO is mixed into production at an approximately 1-to-1000 ratio to the polymer, from an applications perspective, that translates to enough E-GO product to support Boeing’s (Chicago, Ill., U.S.) annual production of commercial planes or enough E-GO to create sidewalls and floors for 3,000 electric vehicle (EV) semi-truck trailers.

“This recognition is an exciting opportunity for Mito to be introduced into more robust applications,” Keith adds. “The verification gives us credibility in the marketplace to showcase exactly what we are producing at scale and in large commercial quantities is the same material that is going into resins, coatings and other 3D applications.”

See “MITO spearheads graphene classification initiative that can aid in composites industry adoption” for more information regarding Mito’s initiatives in graphene functionalization.

Read Next

OSCiAl, Genius graphene nanotubes advance EV battery pack properties

Addition of graphene nanotubes to fiberglass-filled polyphenylene sulfide solution make it possible to preserve high thermal and chemical resistance together with stable electrical conductivity.

Read MoreMito Material Solutions cuts ribbon on new facility in Indianapolis

The graphene additive developer, which serves sporting goods and other composites markets, grows its capabilities with a new facility that includes in-house R&D and testing space.

Read MoreFunding round expands MITO Material Solutions composite technology operations

The woman-led graphene company raises $4.6 million for Indianapolis operations expansion and adds to its Board of Directors.

Read More