Kordsa pursues composites R&D

Turkish reinforcements supplier posts record number of patents and inventions, with over 25% from its Composites Technologies Center of Excellence.

Kordsa (Istanbul, Turkey), an affiliate of Turkey’s largest industrial and financial conglomerate Sabancı Holding (Istanbul, Turkey) reports a 60% growth in its patent portfolio for 2017 with a total of 664 patent applications, 168 patents granted and 167 discrete inventions by year end.

Kordsa's number of inventions, which increased by 14% in 2017 were split between its R&D Center in Izmit (71%) and its R&D Center in Composite Technologies Center of Excellence (26%). The latter was opened in 2016 in Istanbul, colocated and established in collaboration with Sabancı University to bring together engineers, researchers, faculty members, students, entrepreneurs and designers under one roof. It comprises

- Kordsa Prepreg Production Line

- Kordsa Composite Reinforcement R&D Center

- Sabancı University PhD Programs

- Incubation Centers

- Kordsa – Sabancı University Joint composite labs

In parallel to its strong R&D and innovation activities, which is an integral part of its company culture, Kordsa continues to develop technologies that will advance the industries it operates in. Following the record number of patent activity in 2016 (407 applications, 121 patents granted, 128 inventions), Kordsa’s level of achievement in 2017 sets a new record.

SOURCE: KORDSA Reinforcer magazine.

With more than 40 years of experience in weaving and coatings production, Kordsa exports reinforcement technologies to the world as well as carrying out collaborative projects on a global scale. It also pioneers an open innovation approach.An example of its composites R&D activity includes work with Ford Otosan (Gölcük, Turkey) — Ford’s lead commercial vehicle production base in Europe — on composite tandem rear leaf springs in conjunction with the Scientific and Technological Research Council of Turkey.

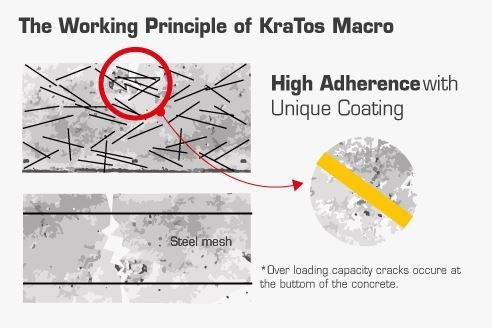

KORDSA also is a global leader in nylon fiber-reinforced concrete, which replaces steel mesh reinforcement to reduce weight and prevent early age shrinkage and cracks compared to basalt and polypropylene fibers. Accredited tests conducted at Aachen University in Germany showed that the use of 600 g/m3 of KraTos Synthetic Fiber Reinforcement prevents 99% of the shrinkage cracks in concrete.

Related Content

-

Büfa partners with Končar to develop composite electric rail platform

Končar-Električna to use Büfa fire-retardant composite materials for electric vehicle development.

-

SABIC debuts EN45545 rail-compliant, fiber-reinforced compound

LNP Thermocomp AM DC0041XA51 offers the rail industry a solution that can be used for on-demand printing of large, complex exterior and interior parts in relatively small build numbers.

-

Composites reinvent transportation

Celebrating National Composites Week, CW shares ways in which composites continue to evolve mass transit.