KraussMaffei opens second R&D pultrusion line

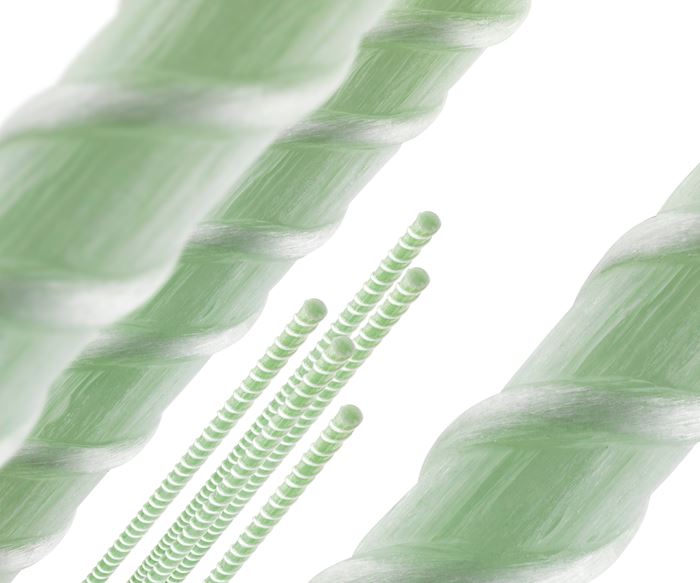

KraussMaffei’s TechCenter in Munich now features two pultrusion lines, one to fabricate rebar and the other to fabricate flat profiles.

KraussMaffei (Munich, Germany) reported on Jan. 16 that it has opened the second pultrusion line in its TechCenter of the Reaction Process Machinery division in Munich. The new system is designed to manufacture composite rebar to provide reinforcement for concrete structures. Together with the first pultrusion system of the TechCenter – an iPul system for flat sections – KraussMaffei offers a research environment to develop and test new processes and applications in pultrusion.

"Pultrusion is a simple way to produce cost-effective profiles, there are hardly any turnkey offers and it is a growth technology. In addition, we are knowledgeable about fibers, metering technology and associated process technology," says Sebastian Schmidhuber, head of development for Reaction Process Machinery at KraussMaffei, explaining the motivation of KraussMaffei to enter the pultrusion market a year ago.

The result of the most recent development work is the iPul system that was launched in 2017, which opened up new applications in pultrusion with significantly higher production speeds than the usual conventional tub or pull-through processes. "Together with the first iPul system, a flat profile system, we offer our customers a comprehensive and globally unmatched range of research and development opportunities in the field of pultrusion," Schmidhuber said.

KraussMaffei says pultruded rebar based on epoxy and reinforced with glass or (conceivably) with carbon fiber offers an enormous potential in the construction industry. "They are corrosion-resistant compared to classical steel reinforcements. Therefore, the overlaying concrete layers can be considerably thinner," Schmidhuber explains. Further advantages include low weight and consequently cheaper transport, easier handling at the construction site and the fact that the fiber-reinforced rebar can be produced endlessly and wound onto drums at the end of the pultrusion system. Typical application areas are in infrastructure or in environments susceptible to corrosion in functional buildings.

KraussMaffei says that to date, finding a means of efficient production has been point of failure of an implementation suitable for series production. "The classic production speeds for rebar in the conventional tub or pull-through processes are still at relatively low haul-off speeds, in some cases under 0.5 m/min. With the new iPul system, we are aiming at up to six times faster speeds in our TechCenter and therefore offer a cost-effective alternative to conventional steel reinforcements," Schmidhuber says. KraussMaffei works closely with Evonik, which has developed an epoxy resin for this application. Additional partners are Thomas Technology (radius pultrusion) and Alpex (mold technology).

The iPul system is used in collaboration with companies such as Covestro in the field of new window profiles that are polyurethane-based. With the new iPul system and the significantly higher production speeds, KraussMaffei says, the process is already getting closer in efficiency to established technologies, which opens new markets for this technology. An additional research partner for this system is Huntsman. Here both companies work on the development of pultruded reinforcement elements for particularly large-format robot blades in wind turbines.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.