MAN Truck & Bus expands zero-emission vehicle portfolio

Small truck series with hydrogen combustion featuring Type 4 tanks is planned for 2025, complementing the commercial vehicle manufacturer’s battery-electric portfolio.

The new hydrogen combustion lorry is based on the proven TG vehicle series. Source | MAN Truck & Bus

Commercial vehicle manufacturer MAN Truck & Bus (Munich, Germany) says it will be the first European truck producer to launch a small series with a hydrogen combustion engine. Installed with Type V hydrogen tanks, the MAN hTGX hydrogen combustion truck, planned for around 200 units, will be delivered to customers in Germany, the Netherlands, Norway, Iceland and selected non-European countries as early as 2025.

The MAN hTGX offers an alternative zero-emission drive variant for special applications, for example for transporting heavy goods like construction work, tank transport or timber transport. The hTGX can also act as an environmentally friendly alternative to battery-electric trucks for use in areas without sufficient charging infrastructure or for markets where sufficient hydrogen is already available. MAN will hand over its battery-electric truck to customers for the first time in 2024 and scale it up from 2025. MAN has been offering electric city buses in Europe since 2023.

“We are continuing to focus on battery-electric vehicles to decarbonize road freight transport. These currently have clear advantages over other drive concepts in terms of energy efficiency and operating and energy costs,” says Friedrich Baumann, executive board member of MAN Truck & Bus and responsible for sales and customer solution. “However, trucks powered by hydrogen combustion engines are a useful addition for special applications and markets. We anticipate that we will be able to best serve the vast majority of our customers’ transport applications with battery-powered trucks. For special applications, hydrogen combustion or, in the future, fuel cell technology is a suitable supplement. The hydrogen combustion engine H45 is based on the proven D38 diesel engine and is produced at the engine and battery plant in Nuremberg. The use of familiar technology enables us to enter the market at an early stage and thus provides a decisive impetus for the ramp-up of the hydrogen infrastructure.

The hydrogen drive is particularly suitable for special transport tasks that require a special axle configuration or where there is no space for the battery on the frame due to the need for truck body work. The MAN hTGX offers high payloads and maximum ranges of up to 600 kilometers in its initially offered 6×2 and 6×4 axle variants. The H45 hydrogen combustion engine used has an output of 383 kilowatts (kW) or 520 horsepower and a torque of 2500 nanometers at 900-1,300 rpm. The direct injection of hydrogen into the engine ensures particularly fast power delivery. With hydrogen compressed to 700 bar (CG H2) and a tank capacity of 56 kilograms, the vehicle can be refueled in less than 15 minutes. With less than 1g CO2/tkm, the MAN hTGX will fulfill the criteria as a “zero-emission vehicle” under the new planned EU CO2 legislation.

Dr Frederik Zohm, executive board member for research and development, adds hat “the new CO2 regulations at EU level will classify trucks with hydrogen combustion engines as zero-emission vehicles. This means that such vehicles fully contribute to our CO2 fleet targets, which also opens the door for this small series that complements battery electric vehicles. At the same time, depending on the country, our customers benefit from corresponding toll reductions, for example. We will continue to research fuel cell technology based on battery technology and hydrogen. H2 fuel technology is also in preparation at MAN. However, it will be several years before the technology is really ready for the market and competitive.”

As with e-mobility, MAN not only emphasizes the development and production of innovative and reliable vehicles in line with its “Simplifying Business” claim, but also supports customers with comprehensive service and consulting offers when switching from diesel to zero-emission vehicles.

MAN has a long standing history with hydrogen drives. For example, it presented its first hydrogen-powered bus 1996; the SL 202 city bus was powered by a natural gas engine that had been modified for hydrogen operation. Following the Hanover Fair, the vehicle completed a three-quarter year test phase in Erlangen, during which it traveled 13,000 kilometers and carried 60,000 passengers. The bus finally arrived in Munich in 1997 and was successfully deployed in regular service there. This was followed in 1998 by three articulated buses for Munich Airport, which were used until 2008, and an additional 14 hydrogen-powered buses between 2006 and 2009.

In addition to its earlier and more recent experience with commercial vehicles, MAN is now also developing and testing the hydrogen engine for the MAN Engines division in a wide range of applications on and off the road as well as on water. For example, it is well suited for special vehicles — such as snow cats — for trains on non-electrifiable routes and for excavators and cranes. Use in combined heat and power plants also makes sense, especially if the heat generated can be used in addition to the electricity.

Related Content

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreTPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

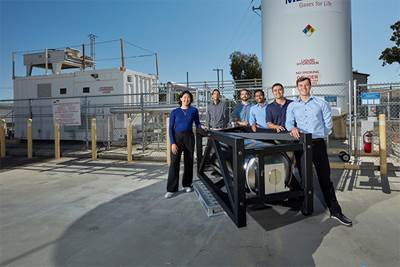

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Forvia moves toward more sustainable automotive composites manufacturing

Automotive technology supplier Forvia shares sustainability goals and recent developments aimed at bio-based and recycled materials and ramping up hydrogen tank production for clean mobility.

Read MoreVerne, Lawrence Livermore demonstrate CcH2 system for heavy-duty transportation

Testing indicates that Verne and Lawrence Livermore National Laboratory have tripled previous records for cryo-compressed hydrogen storage, developing a CcH2 system large enough to meet the energy storage needs of semi-trucks.

Read MoreFord Trucks chooses Hexagon Purus to equip FCEV heavy-duty truck

A purchase order for Hexagon’s Type 4 hydrogen vessels will aid in the development of an FCEV prototype per Horizon Europe’s ZEFES program decarbonizing long-haul trucks in Europe.

Read More

.jpg;maxWidth=300;quality=90)