Verne, Lawrence Livermore demonstrate CcH2 system for heavy-duty transportation

Testing indicates that Verne and Lawrence Livermore National Laboratory have tripled previous records for cryo-compressed hydrogen storage, developing a CcH2 system large enough to meet the energy storage needs of semi-trucks.

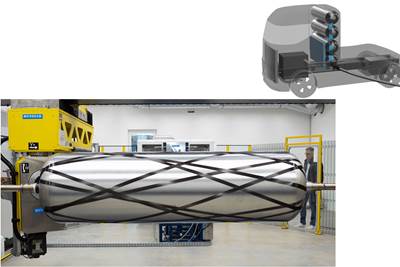

Example of Type III carbon fiber/epoxy-overwrapped aluminum pressure vessel used in Verne’s heavy-duty cryo-compressed hydrogen (CcH2) storage systems. These systems have been tested and demonstrated under cryo-compressed hydrogen operating conditions. Photo Credit: Verne

Verne (San Francisco, Calif., U.S.), a cleantech startup providing high-density hydrogen solutions for zero-emission trucks and other heavy transport, and Lawrence Livermore National Laboratory (LLNL, Calif., U.S.), have demonstrated a single cryo-compressed hydrogen (CcH2) system with a capacity of 29 kilograms, close to three times greater capacity than previously known examples. It is claimed to be the first CcH2 system large enough for use in heavy-duty transportation systems. For example, two such systems can be frame-mounted to a Class 8 truck, and enable a range of more than 500 miles, according to Verne analysis.

Heavy-duty vehicles including trucks, ships and planes are responsible for 23% of U.S. greenhouse gas (GHG) emissions, yet are difficult to decarbonize due to their high energy requirements. Current battery electric and hydrogen storage methods (liquid and compressed gas) do not provide sufficient energy density to power Class 8 trucks.

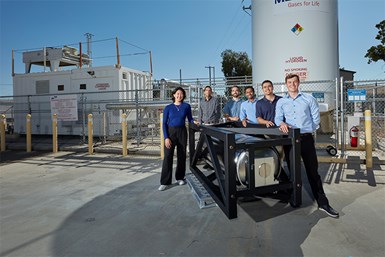

LLNL and Verne researchers (from left to right): Kara Zhang, a Verne process engineer; LLNL mechanical engineer Nick Killingsworth; Ted McKlveen, Bav Roy and David Jaramillo, all co-founders of Verne; and Verne mechanical engineer Harry Clarke. The researchers are standing next to Verne’s cryo-compressed hydrogen storage system, which has an internal volume of 445 liters or about 117 gallons. LLNL’s cryogenic hydrogen fueling facility is in the background. A liquid hydrogen Dewar is to the right and the white transportainer to the left houses a Linde liquid hydrogen pump that can dispense cryogenic compressed hydrogen gas up to 875 bar at up to 100 kilograms/hour. Photo Credit: LLNL

CcH2, on the other hand, achieves 27% greater hydrogen storage density than liquid hydrogen and more than 75% greater hydrogen storage density than compressed gaseous hydrogen. Vernes reports that the energy stored in its 29-kilogram CcH2 tank is roughly equivalent to a 1-megawatt-hour battery storage system, while weighing only about 400 kilograms versus the 1-megawatt-hour battery which weighs around 5,000 kilograms. This magnitude improvement in gravimetric energy density is a major reason why hydrogen is the preferred fuel for the heavy-duty industry.

Verne and LLNL have worked together for the past 2 years to test Verne’s hydrogen storage systems, building on early CcH2 research at LLNL that was started more than 25 years ago by Dr. Salvador Aceves. In this test, Verne implemented a test manifold that enables the testing of multiple components at once. This allows Verne to test and validate various types of safety valves, operating valves and sensors.

“Despite the promise from early hydrogen-fueled truck pilots, the efficient storage of hydrogen onboard trucks, ships and planes remains one of the main challenges to unlock a zero-emission future,” David Jaramillo, co-founder of Verne, says. “Verne has developed high-density, lightweight hydrogen storage systems for use onboard heavy-duty vehicles at low cost. Our solution builds upon decades of research pioneered at Livermore to provide a reliable, scalable and cost-effective storage solution. We could not have done this without the team at Livermore. It’s exciting to see this project head toward the commercialization phase.”

Verne’s CcH2 system is compact enough that it can fit where diesel tanks are typically installed on a Class 8 truck, on the side of the truck between the wheels. Verne has received interest in its CcH2 systems from a variety of industry stakeholders, including Amazon, an investor in Verne.

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreAutomotive chassis components lighten up with composites

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

Read MoreRead Next

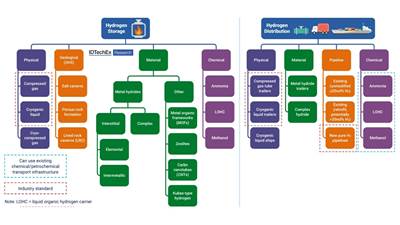

Report addresses advancements, challenges in hydrogen value chain

IDTechEx gives an overview of the solutions that currently exist for hydrogen storage and distribution, and how these two components are vital to ensuring the full potential of this rapidly growing sector.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreFord Trucks chooses Hexagon Purus to equip FCEV heavy-duty truck

A purchase order for Hexagon’s Type 4 hydrogen vessels will aid in the development of an FCEV prototype per Horizon Europe’s ZEFES program decarbonizing long-haul trucks in Europe.

Read More