Michelin, GM develop airless wheel prototype

The wheel design incorporates a combination of fiberglass and other materials to reduce maintenance and safety risks for passenger vehicles.

Share

Read Next

Source | Michelin

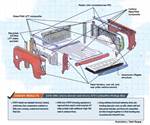

Michelin (Clermont-Ferrand, France) and General Motors (Detroit, Mich., U.S.) recently developed a prototype of their airless wheel technology for passenger vehicles, called the Michelin Uptis Prototype. The wheel, expected to be ready for production by 2024, comprises a combination of resin-embedded fiberglass, composite rubber and aluminum in an airless design for the weight and speeds of passenger vehicles.

Michelin and GM are testing the Uptis Prototype, beginning with vehicles like the Chevrolet Bolt EV. Later this year, the companies say they will initiate real-world testing of Uptis on a test fleet of Bolt EV vehicles in Michigan.

Source | Michelin

The wheel assembly is intended to make driving safer by eliminating the risk, downtime and maintenance associated with flat tires and blowouts, as well as reducing the use of raw materials for the production of replacement tires. The wheel is also designed for use with autonomous and electric vehicles.

The Uptis Prototype represents an advancement toward achieving Michelin’s VISION concept, which was presented at the Movin’On Summit in 2017 as an illustration of Michelin’s strategy for research and development in sustainable mobility. The VISION concept introduced four main pillars of innovation: airless, connected, 3D-printed and 100% sustainable (entirely renewable or biosourced materials).

“Uptis demonstrates that Michelin’s vision for a future of sustainable mobility is clearly an

achievable dream,” says Florent Menegaux, CEO for Michelin Group.

“General Motors is excited about the possibilities that Uptis presents, and we are thrilled to collaborate with Michelin on this breakthrough technology,” says Steve Kiefer, senior vice president, global purchasing and supply chain, General Motors. “Uptis is an ideal fit for propelling the automotive industry into the future and a great example of how our customers benefit when we collaborate and innovate with our supplier partners.”

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

-

Composites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

.jpg;width=70;height=70;mode=crop)