Middle River Aerostructure Systems deploys Plataine AI-based optimization software

Material management, nesting and cutting are now digitally integrated and managed automatically in MRAS facility for complete, streamlined production processes.

Photo Credit: Plataine

Middle River Aerostructure Systems (MRAS, Baltimore, Md., U.S., acquired by ST Engineering North America), an aerospace manufacturer for composites-intensive engine nacelles and aerostructures, has deployed Plataine’s (Waltham, Mass., U.S.) AI-based optimization solution to automate and streamline production processes in its Maryland-based manufacturing facility. The solution reportedly enhances MRAS’ agility and improves quality while reducing material waste.

The project was completed in two phases with best-practice optimization in mind. First, the material management, nesting and cutting was digitally integrated. This was followed by automation of the composite time-sensitive material (TSM) management.

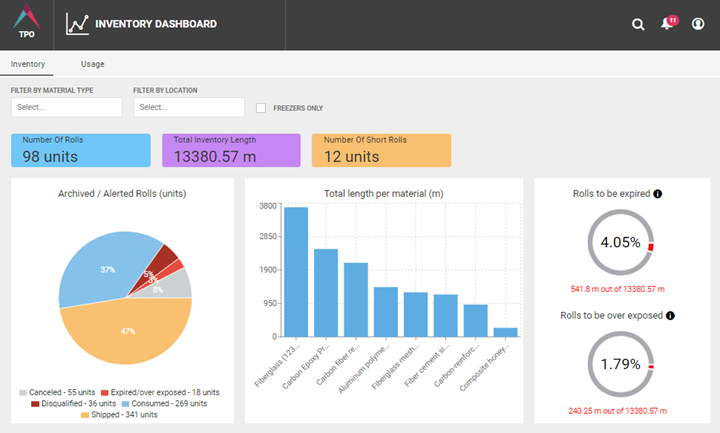

According to Plataine, its software solution enables MRAS to automatically track the location of raw materials as well as remaining shelf-life and expiration of all materials across their freezers, storage locations and production areas. The software also assigns material to work orders and dynamically creates optimal cut plans. The result is complete automation of the cutting process and improved material utilization.

MRAS now benefits from improved on-time delivery and maximized production efficiency. Stakeholders are said to be able to track the Digital Thread from end to end to ensure complete digital visibility of the process. As a result of the deployment, MRAS has already seen significant improvement in material yield.

“Plataine was the right strategic partner to support us with our digital transformation goals,” Frank Dougherty, SVP and GM at MRAS, says. “Plataine’s solution maximizes process automation while minimizing manual effort and errors. The company provides our staff with recommendations and alerts in real-time improving overall efficiency.”

Related Content

-

Airbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

-

Broetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

-

Modular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

.jpg;maxWidth=300;quality=90)