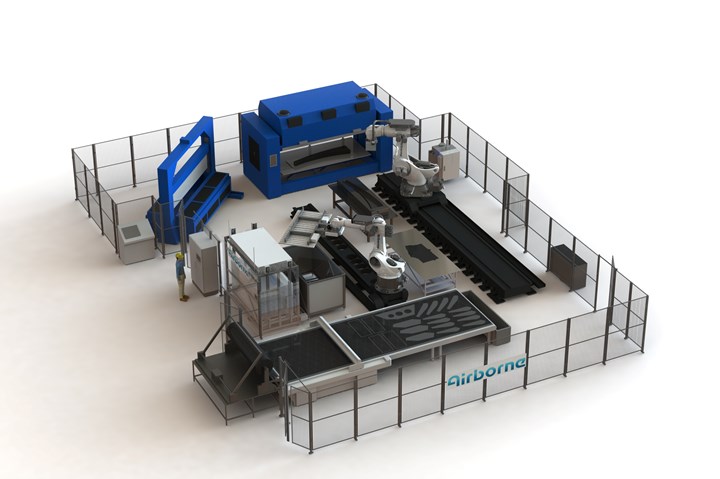

Airborne’s automated ply placement (APP) technology represents the culmination of advancements in robotics, intelligent software and process optimization. It is a robotically operated, automated and modular preforming solution that maximizes composite component design and material freedom prior to resin transfer molding (RTM) processing. Photo Credit: Airborne

The use of composite materials in vehicle and aircraft manufacturing is proliferating. This is due to their many benefits, such as light weight, strength, durability, corrosion resistance and design flexibility. As the demand for composite components in these industries continues to grow, so does the need for high-rate, high-accuracy, flexible, intelligent and modular manufacturing technologies to produce them. Composites manufacturing systems company Airborne (The Hague, Netherlands) set out to address this by creating a concept called automated ply placement (APP).

APP is a robotically operated, automated and modular preforming technology that maximizes composite component design and material freedom before resin transfer molding (RTM) processing. It represents the culmination of advancements in robotics, intelligent software and process optimization.

“APP allows engineers to design for optimal performance without the limitations of hand layup, thanks to the high accuracy of robotics and automation software,” explains Joe Summers, managing director of Airborne UK. “Automated ply placement was invented to improve accuracy, reduce waste and enable the use of composites in any format to be produced in automated manufacturing.”

“Many composite materials come in the format of a roll of material,” Summers continues. “Automated fiber placement [AFP] and automated tape laying [ATL], which convert composite materials into laminates based on tape, are limited to the small portion of composite materials available in slit tape form. Starting with a tape form, typically unidirectional [UD] material, limits the scope for optimizing the resulting part. Conversely, APP can operate with all material formats — not only dry fiber, prepreg or thermoplastic UD tapes, but also textiles like noncrimp fabrics, as well as films, metal-layered sheet material such as cores to make a sandwich panel, pre-consolidated sub-laminates or homogenous materials that come in patches.”

APP process breakdown

In the first stage of the process APP uses a traditional conveyor cutter to precisely cut plies into the required shape. The APP robot(s) then picks up the ply and assesses it for accuracy using a camera-based vision system. It checks that the ply geometry is correct, validates the quality of each cut ply for precision and measures how the ply is positioned on the robot end effector.

A standard conveyor cutter precisely slices plies in the first stage of the process. APP can operate with many material formats, including dry fiber or thermoplastic UD tapes, textiles like noncrimp fabrics, as well as films, metal-layered sheet material such as cores to make a sandwich panel, pre-consolidated sub-laminates or homogenous materials that come in patches. Photo Credit: Airborne

Composite plies ready for processing are oriented and positioned on a welding table — the software adapts the robot movements on the fly to ensure accurate placement. Plies are stacked on the welding table in the correct order required to create a 2D tailored blank laminate and welded via ultrasonic or hot pin welding. The welding activates the binder in the dry fiber material and can also be used for thermoplastic composites. This process is unnecessary for prepreg, but an intermediate step to remove the foil or backing paper can be integrated.

Cut plies not ready for processing are stored in a buffer system, enabling “out-of-sequence” nesting. This reduces material waste because the plies are pre-prepared for production, improving operation cost and sustainability. After processed plies are welded, the robot accurately positions the laminates on a hot drape former in preparation for RTM. A robotic trimming cell is used to trim the outer edges of the preform, ensuring a tight fit in the mold.

For RTM part manufacturing, the prepared net-shape preform is inserted into the cavity of a rigid mold, similar to one used in injection molding. Rigid molds offer the possibility to apply a differential pressure >1 bar, thereby improving impregnation quality and, thus, the laminate quality.

After closing the cavity, the preform is compressed to the final fiber volume content. Resin is injected into the cavity through one or more injection gates to fully impregnate the part, followed by curing at the required temperature and demolding. The essential advantage of RTM concerning the serial manufacture of composite parts is the ability to automate the process for increased production rates.

“An accurate preform is especially important for RTM to ensure good infiltration of the resin and avoid defects in the part,” highlights Airborne CTO, Marcus Kremers. “As part of an RTM composite manufacturing line, APP can control the composite manufacturing process very accurately and repeatedly, without taking a break or needing to be trained for the delicate job, taking the human element and the associated variations out of the composites manufacturing process.”

Airborne’s manufacturing as a service (MaaS) business model enables customers to buy or rent its automation systems. The customizable nature of APP means that customers can define the automated cell’s features. This provides optimized manufacturing solutions to support the various demands of industries such as automotive, aerospace and renewable energy, as well technology research centers, manufacturing companies and more.

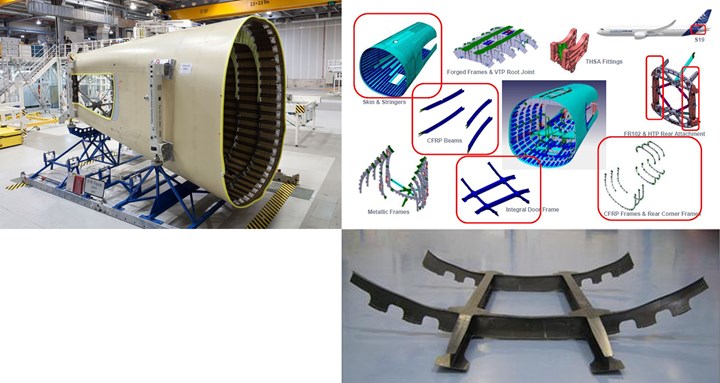

Airbus Getafe A350 production

Airbus (Toulouse, France) employs Airborne’s APP at its Getafe, Spain production plant for the automated manufacture of preforms for the carbon fiber-reinforced polymer (CFRP) rear fuselage beams and maintenance door frame in what Airbus calls section 19 of the A350XWB airframe. The rear fuselage features a co-cured CFRP skin-stringer barrel measuring 6 × 5 meters. The beam supports and doorframe are integrated as a single, co-injected RTM part — uniting two longerons, two lintels and four frame sections — measuring 3 square meters.

Section 19 of the Airbus A350XWB airframe uses RTM'd rear fuselage beams and maintenance door surround. Photo Credit: Airbus

The section 19 integrated frame uses one-component RTM6 epoxy resin and intermediate modulus (IM) carbon fiber reinforcements customized ply by ply and developed in collaboration with Hexcel (Stamford, Conn., U.S.). Optimization used a concurrent approach, which involved the simultaneous development of the raw materials, structural design, manufacturing process and industrial manufacturing solutions.

The 2D preforms are created manually using UD, noncrimp and woven fabric and then hot drape formed into 3D shapes, assembled into the beam structures and infused with RTM6 resin. Airbus developed a customized RTM cell and describes this as high accuracy RTM, adding that it is an efficient method to manufacture these highly loaded primary structures.

The primary driver behind Airbus automating the preform production for this program was to increase quality control by replacing the manual operations, which involve many steps. Such automation in customized RTM cells has been used by Airbus and its Tier suppliers for a variety of parts (see “High-rate, automated RTM line delivers next-gen spoilers”) not only to improve quality and reduce waste, but also to meet increasing production rates, such as the company’s commitment to produce 75 A320 aircraft per month by 2026.

Airborne faced several challenges in developing the APP system to meet this program's needs. First, the size of the parts were quite large. Thus, Airborne adapted the Airbus cell to handle preforms with a maximum size of 3.5 meters. The project also involved various ply shapes and multiple materials. Airborne's accompanying Automated Programming software technology was used to address these challenges (see “Automated Programming, composites 4.0” section later in this article). Finally, this system's production of dry fiber preforms with automated pick and place is a first for Airbus. Thus, Airbus is in the process of qualifying the APP technology and will support it to ensure compliance with production standards.

Automotive Tier 1 supplier

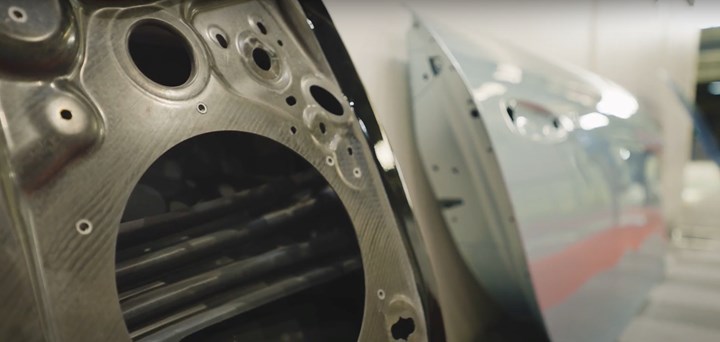

Meeting the high production rate and quality demands of the automotive industry is one of the most challenging feats for manufacturing machinery. As composites have continued to replace other materials in the design and manufacture of cars, producing plies and assembling them to form laminates and components has increasingly become a critical issue. The first automotive application of APP has been developed for a highly engineered dry fiber RTM part produced by Teijin Automotive Technologies’ (Auburn Hills, Mich., U.S.) Pouancé, France facility.

Teijin Automotive Technologies is a Tier 1 supplier of automotive parts, delivering components made using various technologies including sheet molding compound (SMC), thermoplastic composites, thermoset prepreg and RTM. The driver for incorporating APP was Teijin’s customer’s need for a complete composite door for a high-performance sports car with full roadworthiness including compliance with crash safety regulations.

Teijin Automotive Technology’s APP system managed a full composite door produced using dry fiber RTM. Photo Credit: Teijin Automotive Technology

“The main challenge was to design and manufacture the crash structure in composite,” says Teijin Automotive Technologies’ Marc-Philippe Toitgans, director of research and development at the company’s Pouancé, France facility. “Traditionally, composite doors have a metal structure for crash resistance, and to replace this with composite, a very accurate prediction and repeatability study of the composite structure was needed to ensure the structure is safe and qualified.”

“Accurate placement of each ply during manufacturing is crucial, particularly the fiber angles of the sub-surface layers,” Toitgans continues. “With traditional manual layup processes, high-accuracy repeatability cannot be achieved, whereas APP’s vision inspection of each ply and accurate robotic placement can.”

“Another advantage is that APP can accurately cut and place over 30 plies of 2 to 300 grams, which eliminates the problem of gaps and overlaps, and would need to be managed if, for example, AFP was used,” Toitgans adds. “Dry fiber tape or tow placement by AFP has many advantages, but a challenge is accuracy, especially since the tows themselves also have a certain tolerance on the width of the tapes/tows.”

Plies like those seen above are stacked for part thickness variations, with extra layers to provide strength where needed and reduced thickness in areas where the stresses are lower. Photo Credit: Teijin Automotive Technologies

Toitgan notes that, even if accuracy could be managed, there would be many gaps or overlaps, which can influence draping (wrinkles can occur in the areas where gaps are present) or infusion (different permeability). “APP removed this challenge,” he says. After the door’s 2D tailored blanks are made, they are shaped into 3D parts by an advanced, tailormade RTM forming process.

For Teijin Automotive Technologies, dry fiber RTM is an important strategic technology for increasing the rate and accuracy of its composite technologies. The company is already working on future projects with the APP manufacturing approach and equipment.

GKN Aerospace U.K. Global Technology Center

GKN Aerospace’s (Redditch, UK.) Bristol, U.K., Global Technology Centre (GTC) will be the first completed installation of Airborne’s APP technology set for Q3 2023. The 10,000-square-meter research center hosts 300 engineers and collaborates its R&D with universities, the U.K.’s Catapult network and GKN Aerospace’s U.K. supply chain, supporting the design and development of technologies for the decarbonization of aerospace.

It also serves as a base for GKN Aerospace’s technology partnership in Airbus’ Wing of Tomorrow technology program. The primary output for the GTC will be new generations of additive manufacturing (AM), advanced composites, assemblies and Industry 4.0 processes to enable high-rate production of aircraft structures. Its automated preforming cell, internally known within GKN Aerospace as the advanced automated preforming technology (ADAPT) cell, features Airborne’s APP technology developed by Airborne UK.

The Airborne APP system to be installed at GKN Aerospace’s Global Technology Centre in Bristol, U.K. Photo Credit: Airborne

“The ADAPT cell will be key to developing robust, repeatable and flexible automated deposition, profiling, preforming, trimming and inspection of dry fiber composite parts for the manufacture of high-rate and sustainable RTM processed components,” explains Kevin Barlow, chief technologist, composites, at GKN Aerospace. “The U.K. ATI-funded program ASCEND, as reported by CW in February 2023, will be the first to capitalize on the use of the equipment with the development and showcasing of two key demonstrators of an integrated wingtip and a TE false work box to TRL 6 maturity.”

“Importantly, the ADAPT cell will enable rapid demonstration of other key target products in future technology programs or customer interactions and demonstrates the ‘supply chain enabled development’ part of the ASCEND program acronym and deliverables,” notes Barlow.

GKN Aerospace’s ADAPT cell forms part of an automated system whose subsystems consist of the Airborne-supplied APP, a ply cutter from Assyst Bullmer (Wakefield, U.K.), a hot drape former by PAC Group (Belfast, Northern Ireland, U.K.) and a preform trimming module by Accudyne Systems (Newark, Del., U.S.). “The ASCEND program promotes greater adoption of today’s composite technologies, the industrialization of new technologies and accelerating aerospace production rates to meet future high-volume market requirements,” adds Summers. “The collaboration will help develop technologies from across the U.K. supply chain to develop the advanced materials and automation equipment required to manufacture lightweight structures for sustainable air mobility and road vehicles of tomorrow.”

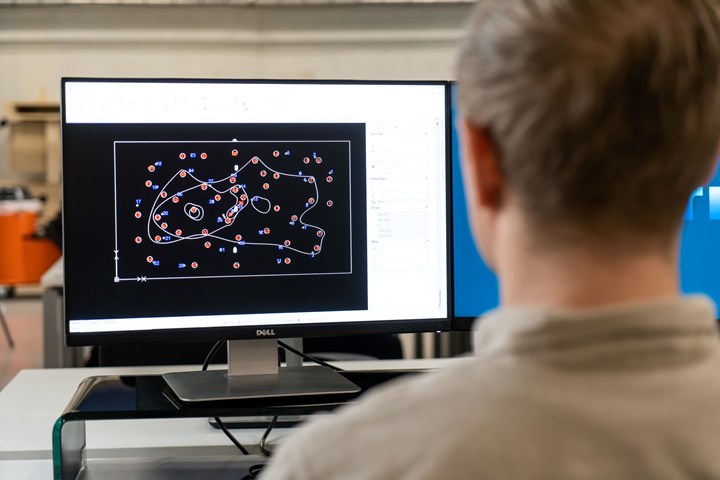

Automated Programming, composites 4.0

The APP system’s key enabling 4.0 technology is Airborne’s Automated Programming software. Traditionally, robots are programmed by humans using a programming language. This process can be time-consuming and error-prone, requiring specialized skills that not all manufacturers have.

Automated Programming means that there is no need for a human programmer to teach robots how to perform a task, enabling fully automated manufacturing processes. The software takes the design and operational input and translates this directly into each ply’s correct robot code and process settings. This is done on the fly, and the system will adapt if the operator uploads a new design or provides a new ply shape, which makes it easy to implement on the shop floor.

This approach of software-driven automation makes the system very flexible, as changes to the design or material can be easily accommodated without the need to teach or reprogram the robots. In addition to eliminating the need for human programming, Automated Programming can automate more complex tasks that require more flexibility, and automate a more comprehensive range of manufacturing processes, leading to significant productivity gains.

The APP software evolved from technology Airborne created for the automated kitting process, which integrates the production steps of nesting, cutting, labeling and kitting into a single production cell. Airborne’s software integrates these manufacturing steps into a single program.

“The software development has been significant to enable the industrialization and adoption of pick and place in composites,” says Kremers. “Making an R&D setup is one thing, but if you want to bring parts to full production with thousands of different ply shapes, automation is necessary. Automated programs are based on advanced algorithms that can read a manufacturing situation and adapt on the fly, removing the need for excessive programming and machine setup.”

Adaptive pick-up, placement accuracy

The Automated Programming algorithm considers the flexibility of a material and determines the best way to pick up a ply for minimum sagging. Photo Credit: Airborne

While the complexity of software development cannot be underestimated, another challenge was the material handling with robotics.

“Getting the grippers to robustly separate the ply from the rest of the material in the nest, especially for tacky prepreg, was particularly challenging,” Kremers notes. “There can also be uncut fibers, which would result in pulling the whole skeleton from the cutter bed. We integrated sensors that detect uncut fibers and put the system on hold so an operator can intervene.”

Another issue is sagging. Because composite materials are flexible, and the plies are picked by an end effector with an array of grippers, sagging can occur between and outside the grippers. The Automated Programming algorithm considers this and determines the best way to pick up a ply for minimum sagging. For example, the robot may pick up a rectangular ply with a rotated end effector to position the suction cups in the corner of the ply. The amount of gripper force is ply shape-dependent and determined for each gripper.

Placement accuracy is also critical when releasing the ply onto the welding table or buffer system. APP uses on-the-fly calibration based on vision or closed-loop control whereby each ply is scanned when attached to the end effector, and its position is compared with the expected location. The robot’s movement is then adjusted to ensure accurate placement. “Because we scan the ply, the system can control quality, precisely checking the cut edges or to find defects in the ply that may be unseen on the cutter,” notes Kremers.

Buffering and replay

The APP system’s automated kitting capability involves a buffer solution for sorting and sequencing. After cutting the materials into 2D plies, the robot can automatically put them in the buffer if needed, sort the plies into kits per part and sequence the plies into the correct order to enable easy layup later. The buffer is also accessible from outside the cell so that the kit or preform can easily be offloaded manually or by another robot.

If things go wrong, a digital record of the system’s operations, part locations, time, temperature, speeds, etc., can be referred to as a “replay” tool, which is especially important as the code for these processes is generated in real time. This data also feeds into a virtual replica of physical assets, providing real-time insights and predictive analysis for future process improvements.

Future APP development, applications

Regarding APP’s future potential, Kremers says, “Software development is something we are constantly doing to improve the speed and robustness of the system, especially as the data we harvest has a lot of potential to provide more capability and performance for the customer. For example, now the system inspects every ply before placement. You can foresee the accuracy of plies that are directly picked from the cutter is quite decent, and the system only makes a minimal correction or none at all. If the system recognizes this trend, you could skip the inspection or reduce the frequency and inspect, for example, only one in every ten plies, improving the output.”

“Another example can be that there is a particular dependency on the material,” he continues. “Some materials are more difficult to cut and get clean edges than others, and the system can see this and provide insights on how to set up the cutter properly or to have a more frequent change of the cutting knives or use different cutting methods for other materials.” Additionally, there is material welding development in the software: if binder quality or quantity changes, the system can potentially recognize this from the welding data.

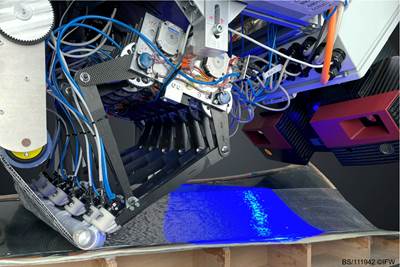

Plies are robotically placed on a laminating table in preparation for welding. Photo Credit: Airborne

Optimized for minimum waste, output or CO2

Although the APP system is automated, there is a tradeoff to be made between maximum output and minimum waste. This can change daily in a typical factory. Airborne is developing software to “Optimize for X” so the operator, or the digital factory management system, can select a desired optimization scenario, for example, for minimum waste, maximum output or a minimal CO2 footprint, if they wish to do so. This is the basis of flexible automated manufacturing, or Composites 4.0.

When a mode has been selected, such as minimal CO2, the automation software considers the potential productivity impact and end effector compatibility factors. It evaluates the overall effect on the manufacturing process to adapt the machine instructions on the fly for the desired result.

Airborne plans to use this technology to optimize its automated cells for various customers, enabling operators to stipulate different scenarios and make informed decisions. Airborne is also testing APP and its automated programming with recycled fibers and resins, biomaterials and hybrid combinations of thermosets, thermoplastics and metals to validate the automated software’s ability to identify defects and compensate.

“Should the development be successful, it can open doors for recycled and low CO2 applications in various industries,” explains Kremers. “To make composites more sustainable, it’s important to use less energy, fewer steps and reduce waste.”

The embedded energy in carbon fiber is relatively high, so reducing waste and using alternative fiber with a lower CO2 footprint is crucial for sustainability. Additionally, integrating technologies like 3D printing or robotized injection overmolding can be tailored to the unique needs of any APP application.

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Plant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreAutomated manufacturing solutions from Airborne

I had the chance recently to interview Marcus Kremers, chief technology officer of Airborne International (The Hague, Netherlands), who told me about his company’s growing smart automation initiatives for its customers.

Read MoreModular draping system shows potential for wrinkle-free, automated dry fiber layup

Through research programs FlexProCFK and AutoBLADE, Leibniz University and partners are developing a robot-mounted layup system for complex CFRP parts.

Read More