NASA exploring using carbon nanotube for aerospace applications

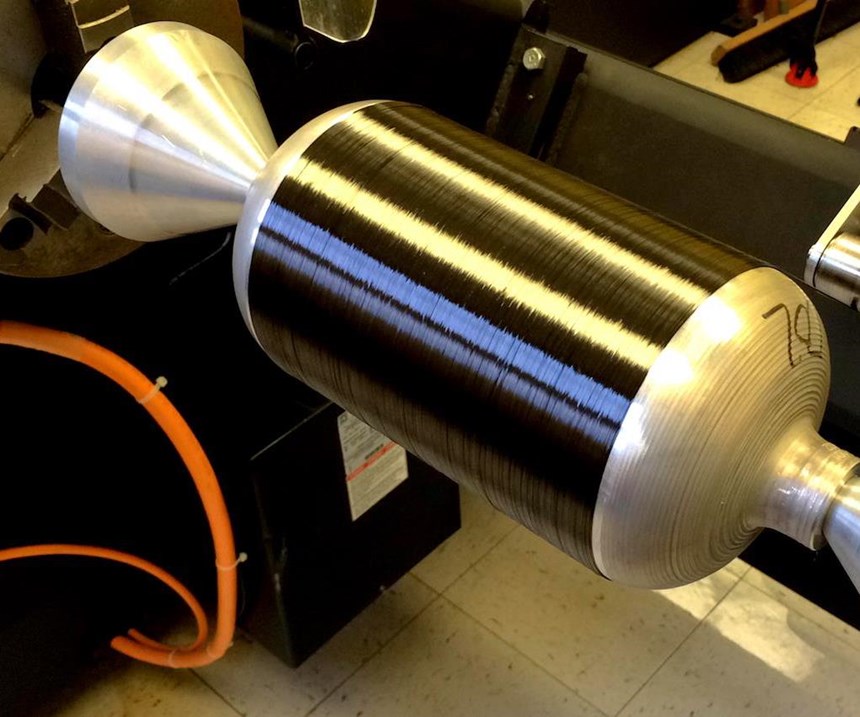

NASA worked with Nanocomp to produce carbon nanotube (CNT) fibers to fabricate a carbon nanotube Composite Overwrap Pressure Vessel.

NASA’s Space Technology Mission Directorate (STMD) is interested in nanotechnology – an approach that can reduce the mass and improve the performance of aerospace systems. For example, NASA computer modeling analysis has shown that composites using carbon nanotube reinforcements could lead to a 30 percent reduction in the total mass of a launch vehicle.

“No single technology would have that much of an impact to reduce the mass of a launch vehicle by that much,” says Michael Meador, program element manager for lightweight materials and manufacturing at NASA’s Glenn Research Center in Cleveland, Ohio. “I’m not trying to be cliché, but that is a game changer.”

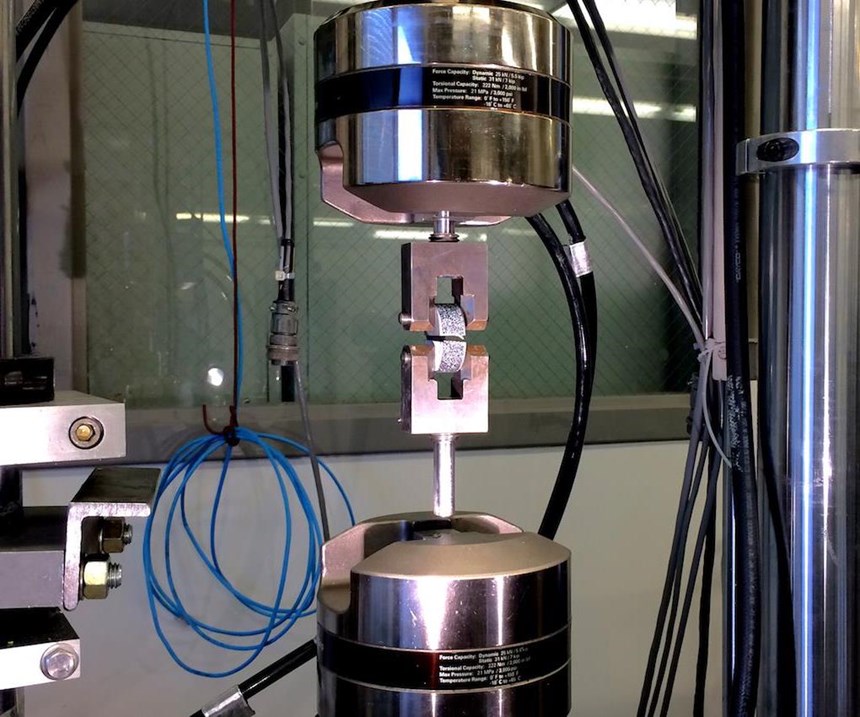

Soon-to-fly hardware will test the tensile properties of a carbon nanotube fiber-based composite tank over that of conventional carbon fiber epoxy composites. A Composite Overwrapped Pressure Vessel (COPV) took to the skies aboard a sounding rocket launched from NASA’s Wallops Flight Facility in Virginia on May 16.

“We’re going to use the COPV as part of a cold-gas thruster system,” Meador says, noting that this involves moving the rocket’s payload during its flight, as well as spinning up the payload to improve the rocket’s aerodynamics during its descent to Earth. “We are one experiment in that payload, but it’s a pioneering flight. This is first time that carbon nanotube-based composites have been flight-tested in a structural component,” he says.

The COPV project has involved several NASA centers – Glenn Research Center, Langley Research Center, the Marshall Space Flight Center – as well as industry. NASA collaborated with Nanocomp (Merrimack, NH) to make nanotube yarns and sheets, with the space agency developing specialized processing methods to fabricate COPVs.

“We were interested not just in developing high-strength composites from carbon nanotube yarns but also in demonstrating their performance by building an actual component and flight testing it,” Meador says. “The COPV flight test will go a long way in showing that these materials are ready for use in future NASA missions.”

The suborbital rocket flight of a COPV is a first step, says Emilie Siochi, a research materials engineer at NASA’s Langley Research Center. “This COPV represents the first large item that we’ve built” by turning nanotube yarns into composites. Early on at the start of the initiative, she says carbon nanotube fiber material was only available in small quantities. That needed to change.

“We had to improve the properties, improve the quality and the quantity,” Siochi says. The NASA-industry relationship was invaluable to scale up the material for space agency use, she says, and qualifying the COPV for a flight test has assisted in maturing the technology too.

“There’s potential for the structural properties of carbon nanotubes to be much stronger than carbon fiber composites, now the state of the art for structural material,” Siochi says. “So if it’s stronger, we’ll be able to build lighter structures needed for access to space.”

Meador sees a bright and long-lasting future for carbon nanotube materials.

“When we first started to get into nanotechnology research we were looking at where did it make sense for NASA to invest…where could a huge payoff be for the agency, be it in weight savings, performance, or reduced power consumption,” Meador suggests.

There’s more work to be done in terms of improving the material’s mechanical properties, as well as fabricating the yarn fiber in quantities to make it competitive with conventional carbon fiber.

“There’s a big payoff, not just for aerospace applications,” Meador says. Use of carbon nanotube materials, say in cutting down the weight of ground transportation vehicles, could lead to a huge savings from less fuel consumption and also lessening carbon dioxide emissions. Likewise, the insertion of the technology into aircraft is another area that deserves further attention, he adds.

“We’re not looking at magic materials. Rather, we’re finding that when you get down to the nanoscale, there are certain features of materials at that scale that give rise to new properties, new physics that you don’t see above that scale,” Meador says. “And that’s what it’s all about. Seeing how you can control and exploit those properties.”

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreNatural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More