Orbital Composites introduces Orb 1 industrial-grade robot 3D printer

Controlled by Orbital Composites’ proprietary Orb OS software, the operating system allows users to easily print end-use thermoplastic composite parts from CAD files.

Orbital Composites, Inc. (San Jose, Calif., U.S.) launches “Orb”, an Industry 4.0 robotic 3D printing platform that is highly modular, scalable and rapidly deployable. Controlled by Orbital Composites’ proprietary Orb OS software, the operating system allows users to easily print end-use thermoplastic composite parts from CAD files.

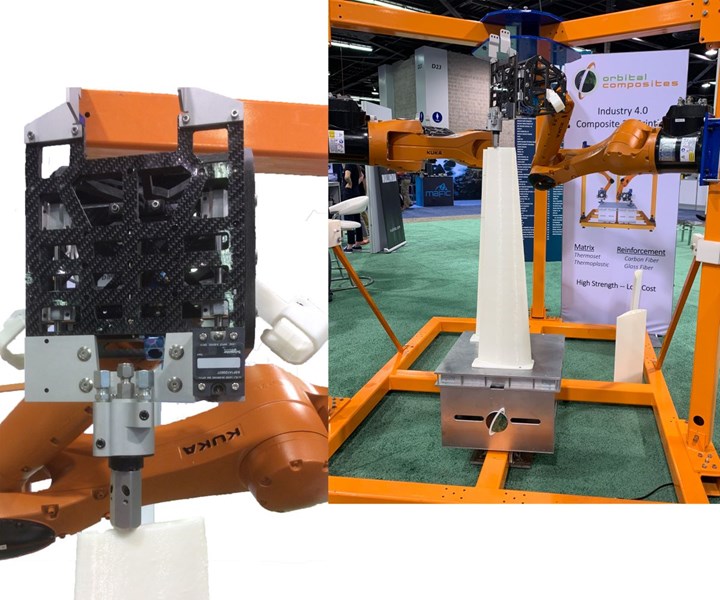

Orb 1 is the first of a family of industrial-grade robot 3D printers to be launched based on the Orb platform. It comprises a frame-mounted robot with a high-volume thermoplastic printhead and 1 meter by 1 meter build platform. Its reconfigurable robot mounting positions give users the flexibility to print very tall, long or wide parts.

The Orb 1 robot printer can be programmed easily using standard desktop slicing software like Simplify3D and the Orb OS that automates robot and

print-head programming, minimizing the engineering investment required to support full scale production. Orb OS can synchronize data up-to-the-millisecond across thousands of cloud robots and IoT devices like motors, heaters, cameras and a variety of sensors. “Our clean-slate approach allows us to digitize the entire printing process over a standard ethernet IP-based architecture and has the ability to capture, analyze and react to various sensor and measurement triggers,” says Orbital Composites founder and CTO Cole Nielsen. “We seamlessly integrate into a 5G-enabled Industry 4.0 environment, allowing mobile factories of the future to be a reality now. Just as software-defined networking revolutionized the modern data center, our novel software approach will revolutionize industrial 3D printing and usher in a new era of software-defined manufacturing.”

The Orb 1 features thermoplastic extrusion, using standard 1.75 millimeter and 2.85 millimeter filaments and multiple print resolutions. The filament driver and motors have been custom designed for maximum efficiency and reliability, enabling large prints. Pre-qualified materials include PLA, nylon, carbon fiber-reinforced nylon with other materials to be qualified over time. The lightweight end-effector leverages a state of the art fluid dynamic design and a carbon fiber composite chassis to ensure reliable print runs.

Based on its belief that robotic industrial 3D printers are the most efficient way to scale high-volume production of large parts and enable printing of complex 3D shapes on curves, Orbital Composites uses the KR10 R1100 industrial robot from Kuka, which has strong worldwide service support network. Orbital Composites is an official Kuka System Partner.

The company is taking pre-orders for the Orb 1 units to ship Q1 2020. https://www.orbitalcomposites.com

Related Content

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

.jpg;maxWidth=300;quality=90)