Orbital Composites, Inc.

1758 Rogers Ave.

San Jose, CA 95112 US

510-825-9555

amolak@orbitalcomposites.com

orbitalcomposites.com

About Orbital Composites, Inc.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Orbital Composites, Inc. Supplies the Following Products

- Acrylonitrile butadiene styrene (ABS)

- Aerospace, aircraft interior

- Aerospace, fuselage/wing

- Aerospace, radomes

- Aramid

- Architectural design

- Armor, ceramic

- Armor, composite

- Automated fiber placement

- Automated tape laying

- Automotive, body panels & substructures

- Basalt

- Bismaleimide (BMI)

- Boron

- C-Glass

- CAD/CAM/CAE design

- Carbon, PAN-based

- Carbon, pitch-based

- Carbon, rayon-based

- Carbon/carbon composites

- Ceramic

- Ceramic matrix composites

- Compression molding

- Consulting, business development/acquisition

- Consulting, materials

- Consulting, other

- Consulting, process development

- Consulting, structural design

- Continuous fiber/thermoplastic resin

- Continuous fiber/thermoset resin

- Cutting, finishing, and machining

- Cyanate ester

- Discontinuous fiber/thermoplastic resin

- Discontinuous fiber/thermoset resin

- E-Glass

- Education/Training

- Epoxy, 250 F cure

- Epoxy, 350 F cure

- Epoxy, toughened

- Filament winding

- Finite element modeling/analysis (FEM/FEA)

- Honeycomb structures

- Hybrid commingled fibers

- Large format

- Marine, boat (hulls, decks, bulkheads, etc.)

- Moldmaking and patternmaking

- Nylon

- Nylon (polyamide)

- Other composite structures

- Other fabricating services

- Other thermoplastics fabricating services

- Phenolic

- Polyarylene ketone, sulfide

- Polybutadiene

- Polycarbonate

- Polyether ketone family (PAEK, PEKK, PEEK)

- Polyimide

- Polyphenylene sulfide (PPS)

- Polypropylene (PP)

- Polytheylene

- Pressure vessels

- Product design

- Profiles

- Prototyping

- Pultrusion

- Rebar

- Rods

- Silicon carbide

- Small format

- Structural high-strength glass (S- and R-type)

- Structural strengthening / reinforcement services

- Tubes

- Urethane

- UV-curable

- Vinyl ester

Editorial, News, and Products

-

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

-

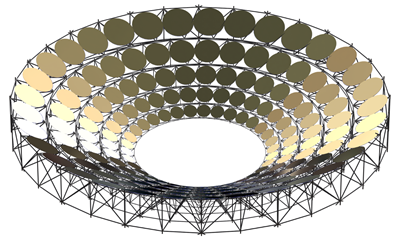

Orbital Composites wins award from U.S. Space Force to build space factories for antennas

Partners Axiom Space, Northrop Grumman Space Logistics and Southwest Research Institute will help advance ISAM technologies for kilometer-scale LEO antennas, space stations and GEO applications, targeting space factory in 3-5 years.

-

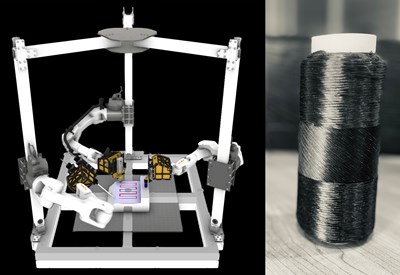

Orbital Composites installs robotic AM system at University of Rhode Island

The 12-axis Orbital S system designed to print continuous fiber-reinforced parts will be used to advance research in composites for underwater unmanned vehicles.

-

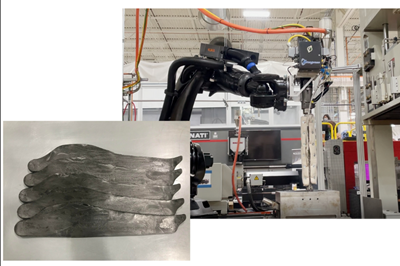

Orbital Composites licenses AMCM technology

Additive manufacturing compression molding (AMCM), co-developed with ORNL, combines robotic AM and continuous fiber technologies to revolutionize high-volume composites manufacturing.

-

Low-void, large-scale, high-volume 3D-printed composites

Among its many composites-related projects, Oak Ridge National Laboratory recently installed its first AMCM test cell, combining extrusion with compression molding for fast, low-void, low-porosity thermoplastic composite parts.

-

Orbital Composites installs robotic manufacturing system at NREL for wind turbine blade research

Customized, automated platform expands NREL’s capabilities for researching blade-finishing technologies and serves as Orbital’s sounding board for applicable composites solutions in aerospace, space and infrastructure.

-

Orbital continues to progress toward commercialization

Orbital Composites is pursuing a variety of collaborative projects to apply its Orbital S robotic additive manufacturing system.

-

Orbital Composites to demonstrate containerized 3D printing robots for AM wind blade manufacture

Project aims to demonstrate additive manufacturing of >100-meter-long composite wind blades with >25% reduced cost.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

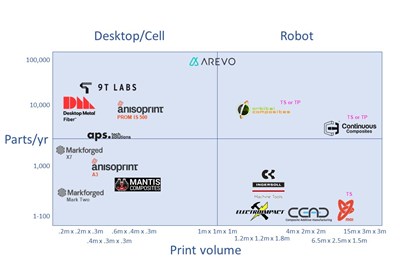

3D printing with continuous fiber: A landscape

Growth continues in suppliers, part size, production volume and markets.

-

Orbital Composites, ORNL collaborate to advance robotic polymer and composite AM

The research will focus on the development of a commercially-ready system capable of robotic overprinting on pre-manufactured non-planar surfaces, with multi-material polymers and continuous fiber.

-

AZL Aachen webinar: Tape integration into injection molding

AZL Aachen is hosting the third webinar in its Lightweight TechTalk series, titled, “Tape Integration Into Injection Molded Parts,” on Thursday, Aug. 13, 5:00 am-6:20 am EDT (11:00 am-12:20 pm CET).

-

Orbital Composites introduces Orb 1 industrial-grade robot 3D printer

Controlled by Orbital Composites’ proprietary Orb OS software, the operating system allows users to easily print end-use thermoplastic composite parts from CAD files.

-

CAMX Additive Manufacturing Workshop speaker: Orbital Composites

The Additive Manufacturing Workshop for Composites at CAMX (Anaheim, Calif., U.S.) will take place on September 25 and will explore the evolution of 3D printing technology and fiber reinforcement.

-

CAMX to host Additive Manufacturing Workshop for Composites

Co-located with CAMX, the event explores the connection between AM and continuous fiber reinforcement.

-

Moving continuous-fiber 3D printing into production

With patents proliferating and production applications emerging, 3D printing with continuous fiber reinforcement is poised for significant market growth.

-

People on the Move: June 2018

CW’s monthly roundup of people on the move in the composites industry.

-

3D-printed composite wind blades and aircraft, closer than you think

Orbital Composites’ patented coaxial extrusion process is investigated at Airbus subsidiary CTC GmbH Stade and spins off advances in speed, scale, materials and multifunctionality as it aims for very large structures.