Plasmatreat presents plasma systems for surface treatment solutions at Fakuma 2021

Company to highlight its atmospheric plasma jet technologies — including Openair-Plasma, which is used for plastic and composite materials — at the Germany-based plastics processing event.

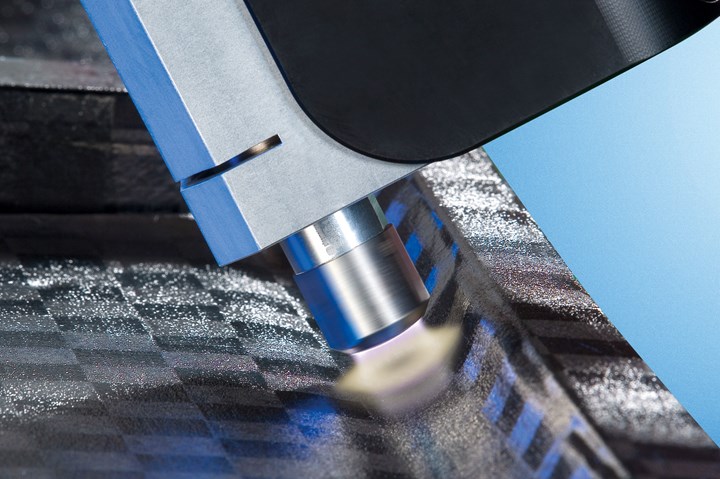

Openair-Plasma can be used for pretreatment of CFRP materials to ensure that dissimilar materials can be bonded together. Photo Credit: Plasmatreat

Plasmatreat GmbH (Steinhagen, Germany) is presenting its systems and solutions for surface treatment with atmospheric pressure plasma at Fakuma — an international trade show for plastics processing — which will take place in Friedrichshafen, Germany, from Oct. 12-16, 2021. Activation and coating of plastic surfaces, as well as for the pretreatment of carbon fiber-reinforced polymer (CFRP) materials prior to subsequent processing operations is the company’s primary focus (see “Atmospheric plasma jet technology rapidly pretreats glass fiber honeycomb sandwich panels”).

During treatment with Openair-Plasma, the company’s atmospheric plasma jet technology, groupings containing oxygen and nitrogen are introduced into the mostly nonpolar plastics to increase surface energy. This activation optimizes the wettability of the surface for increased adhesion and long-term stability of adhesives, paints and coatings.

Nanocoatings can also be applied to material surfaces via the company’s PlasmaPlus noncoating technology, ensuring long-term stable adhesion of sealing systems. Plasmatreat mentions its PT-Bond application as an example. An organo-silicon compound is added to the plasma as a precursor. The chemical composition varies depending on the material and application. The PT-Bond layer itself is bifunctional, meaning it promotes adhesion for both the substrate and the adhesive.

At its booth at Fakuma, the company will be showing various plasma systems and equipment, such as its InMold-Plasma process for injection molding machines. Based on traditional atmospheric pressure plasma technology, activation takes place inside the injection mold itself, further simplifying the manufacturing process. Plasmatreat says the process is ideal for producing plastic compounds from incompatible, hard-soft material combinations using two-component injection molding.

Visitors will also be able to see Plasmatreat’s plasma treatment unit (PTU) with special component transport. In this unit, it is not the nozzles that are moved, but the components, which are transported by three of Beckhoff Automation’s (Verl, Germany) XPlanar Movers — planar motors for levitating product movement — at the right time, to the right nozzle for treatment with Openair-Plasma. Specifically, at the trade show, an inmold plastic part and a component with electronics will be treated by the PTU. An anti-corrosion coating will be applied to a third component using the company’s PlasmaPlus AntiCorr process.