R&D activities recommended to US DOE to achieve super-sized composite wind blades

“Big Adaptive Rotor” project is prioritizing technology to develop land-based 5-megawatt turbine with 100-meter-long blades.

DNV GL recently announced the release of an in-depth study, commissioned by the U.S. Department of Energy’s Lawrence Berkeley National Laboratory, which examines the challenges associated with manufacturing and deploying next-generation, increasingly larger land-based wind turbines. According to the report, in the past decade, the U.S. wind energy industry has achieved significant improvements in energy production and cost efficiency, driven in part by increased turbine, blade and tower size. However, the industry is quickly approaching a logistical cost and capability ceiling as turbine components become too large for existing infrastructure and transportation to accommodate.

Currently, the report says, the largest blades deployed in the U.S. are 67 meters, but blades up to 88.4 meters — or almost as long as a football field — have been deployed in Europe; and blades up to 115 meters are on the horizon. As turbine component sizes increase, logistical constraints can either reduce the number of developable sites or elevate costs, which can make some potential sites economically uncompetitive. Finding new solutions to logistical challenges associated with ever-larger components can enable the wind industry to achieve optimal wind levelized cost of energy (LCOE) options for every region of the United States.

DNV GL explored three innovation pathways to help identify high-value R&D opportunities:

- Innovative transportation: To address physical constraints and challenges, new methods can facilitate the transportation of blades from factories to wind projects via road, rail or air.

- Segmented blades: Segmented or modular blades may enable the use of more cost-effective transportation, but must also account for the impacts on blade design, manufacturing and on-site assembly.

- On-site manufacturing: Deploying a temporary blade manufacturing factory at the project site to fabricate blades from raw materials to finished product largely eliminates transportation challenges associated with longer blades.

“DNV GL identified a number of R&D activities that could make contributions to the viable development of supersized blades. These recommendations are feeding into the U.S. Department of Energy-funded ‘Big Adaptive Rotor’ project to assess and prioritize technology needed to develop a cost-competitive land-based 5-megawatt turbine with 100-meter-long blades,” says Ryan Wiser, senior scientist, Lawrence Berkeley National Laboratory.

The acceleration of R&D to make supersized blades feasible requires collaboration between researchers in the United States, turbine manufacturers, blade manufacturers, and transportation logistics companies. Blades are the most critical component in determining the technical and economic performance of wind turbines. The logistics associated with supersized blades adds additional levels of complexity into the development process, which the industry and researchers must work collaboratively to address.

“To realize continued progress in making wind energy cost-competitive across all regions in the U.S., the wind industry must accelerate R&D in innovative approaches to blade design, manufacture and transportation,” said Richard S. Barnes, executive vice president, Energy North America at DNV GL. “The good news is that there appears to be fertile ground for R&D and accessible solutions on the near horizon.”

According to the report, high-value R&D areas include:

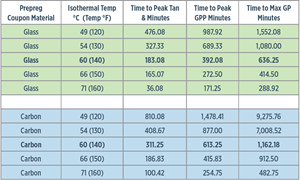

- Further advances in high-stiffness / low-cost materials like industrial carbon fiber and thermoplastics materials;

- Advanced controls and sensor technologies that could be applied to monitor or enable blade bending in transport or monitor or control segmented blade loads such that lower-weight blades can be achieved;

- Reducing the blade chord dimension would enable operation at higher tip speeds and improves blade transport potential, but issues related to aeroacoustics and leading-edge erosion need further improvement; and

- Advanced aeroelastic modeling of dynamic stability and deflections can enable the development of more slender blades that can allow controlled deflection during transport.

Related Content

Real-time assessment of thermoset composites curing

The combination of material state management (MSM) software and an encapsulated sample rheometer (ESR) enables real-time cure recipe management or cure model development inside the autoclave.

Read MoreComposite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)