Refitech expands RefiFLEX range, supplies pultrusion profiles for construction solutions

High-precision carbon fiber square tubes and CarboSix UD carbon fiber pultrusion profiles meet demand for lighter, stiffer, more high-performance systems.

Photo Credit: Refitech

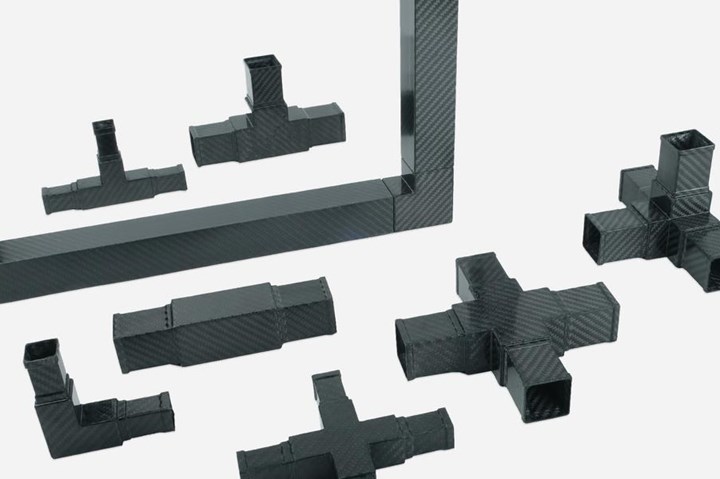

Refitech (Waalwijk, Netherlands) has expanded its range of RefiFLEX carbon fiber square tube construction solutions, which now include a 40 x 40-millimeter high-precision tube with a standard length of 1,600 millimeters, as well as the corresponding connectors, RefiFLEX 40S. Further, Refitech says it can now supply CarboSix (Mondovì, Italy) unidirectional (UD) carbon fiber pultrusion profiles to customers in the Benelux, a politico-economic union in western Europe. The profiles have integrated mounting slots to enable them to be screwed rather than glued together to form frames, using a variety of fixing materials.

“We see a growing demand for lightweight systems,” says Bas Nijpels, sales engineer at Refitech. “As a result, more and more mechanical engineers are starting to use our carbon fiber tubes and profiles. This, in turn, has led to increased requests for larger sized tubes, in addition to our successful 20-, 25- and 30-millimeter RefiFLEX tubes. Like its smaller RefiFLEX comparator, the new 40 x 40-millimeter tube is smooth inside and out, ensuring the connectors can be glued on to fit perfectly. By combining the different RefiFLEX elements, lightweight frames for all kinds of applications can be constructed with ease.”

Nijpels notes that the RefiFLEX tubes and connectors range now includes 18 different shapes and sizes. Moreover, says Nijpel, they continue to meet construction challenges, including high performance at a reduced weight. A recent customer application include large LED screen frames.

Further, as a result of a cooperative agreement, Refitech has now added CarboSix’s construction system to its portfolio. Unlike the multi-layered prepreg RefiFLEX system, the CarboSix profiles consist of UD carbon fiber pultrusion profiles, making them ideal for solutions that require high bending stiffness at low weight. Three available sizes include 90 x 90 millimeters, 90 x 45 millimeters and 45 x 45 millimeters, and have an integrated mounting slot so profiles can be screwed together to form frames.

“These profiles are used to make calibration frames or assembly jigs in the automotive, mechanical engineering and aerospace industries,” adds Nijpel. “These carbon fiber frames and jigs are both lighter and stiffer than their metal counterparts. Compared to aluminum frames, this system can save up to 70% in weight at a comparable strength and stiffness. End-user advantages are not only high dimensional stability and a very low ergonomic load, but also enables more flexibility for adjustment or the rearrangement of components if required in the production process.”

Related Content

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Large-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.