Rocket Lab unveils composite Neutron launch vehicle

Live streamed web event reveals detailed Neutron rocket architecture for the first time, including its carbon fiber launch vehicle and second stage, and new Archimedes rocket engine, all designed for reliability and reusability.

Launch and space systems company Rocket Lab USA Inc. (Long Beach, Calif., U.S.) has revealed new details concerning the design, materials, propulsion and reusability architecture for its next-generation composite Neutron launch vehicle in a virtual event streamed via Rocket Lab’s YouTube channel on Dec. 2 (above).

Building on Rocket Lab’s experience developing the Electron launch vehicle, which is reported to be the second most frequently launched U.S. rocket annually since 2019, the advanced 8-ton payload-class Neutron launch vehicle is designed to transform space access by delivering reliable and cost-effective launch services for satellite mega-constellations, deep space missions and human spaceflight.

According to Rocket Lab, Neutron will be the world’s first large carbon fiber composite launch vehicle, previously pioneered with its use on the company’s orbital rocket, Electron. It is said Neutron’s structure will be comprised of a new, specially formulated carbon fiber composite material undisclosed by the company that is lightweight, strong and can withstand the immense heat and forces of launch and re-entry for frequent re-flight of the first stage. To enable rapid manufacturability, Neutron’s composite structure will be made using automated fiber placement (AFP).

“Neutron is not a conventional rocket. It’s a new breed of launch vehicle with reliability, reusability and cost reduction hard baked into the advanced design from day one. Neutron incorporates the best innovations of the past and marries them with cutting-edge technology and materials to deliver a rocket for the future,” said Rocket Lab founder and CEO Peter Beck during the event. “More than 80% of the satellites to be launched in the next decade are expected to be constellations, which have unique deployment needs that Neutron is the first vehicle to address specifically. Like we did with Electron, rather than starting with a traditional rocket design, we focused on our customers’ needs and worked back from there. The result is a rocket that is right-sized for market demand and can launch fast, frequently and affordably.”

Neutron’s tapered design and wide, robust base, eliminating the need for complex mechanisms and landing legs, emphasizes its reusability — frequent and affordable launch, land and lift-off. The structure’s current design removes the need for bulky launch site infrastructure, including strongbacks and launch towers, instead standing securely on its own legs for lift-off. After reaching space and deploying Neutron’s second stage, the first stage will return to Earth via a propulsive landing at the launch site, eliminating high costs associated with ocean-based landing platforms and operations.

Neutron will also be powered by a new rocket engine, Archimedes. Designed and manufactured in-house by Rocket Lab, Archimedes is a reusable liquid oxygen/methane gas generator cycle engine capable of one meganewton thrust and 320 seconds of ISP. Seven Archimedes engines will propel Neutron’s first stage, with a single vacuum-optimized Archimedes engine on the second stage. Moreover, Neutron’s lightweight composite structure means Archimedes does not need the immense performance and complexity typically associated with larger rockets and their propulsion systems, Rocket Lab notes. A simplified engine, in turn, accelerates the timeline for development and testing.

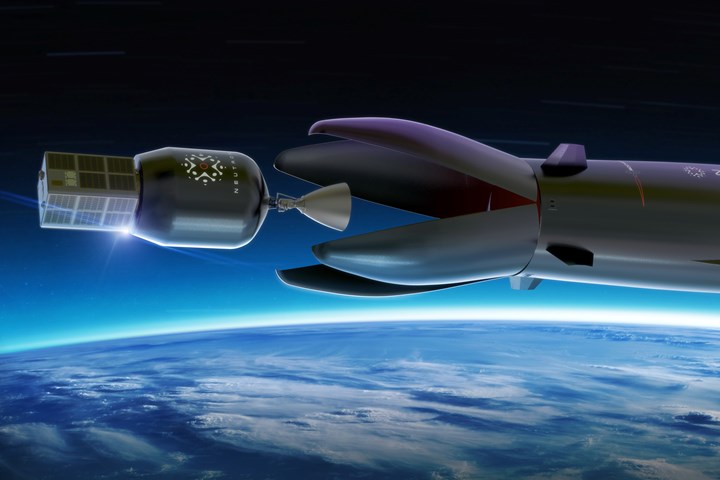

However, Rocket Labs says what truly makes Neutron’s design unique is the captive ‘Hungry Hippo’ fairing design, which will see the fairing form part of the first stage structure and remain fixed to the stage. Rather than separating from the stage and falling away to the ocean like traditional fairings, Neutron’s Hungry Hippo fairing jaws will open wide to release the second stage and payload, before closing again ready to return to Earth with the first stage. What lands back on the launch pad is a compete first stage with fairings attached, ready for a new second stage to be integrated and launched. According to the company, this advanced design can speed up launch frequency, eliminates the high cost, low reliability method of capturing fairings at sea and enables the second stage to be lightweight and nimble.

This method change has also removed constraints related to the second stage’s design, such as exposure to the harsh environments of the lower atmosphere during lift-off. Because it will be completed enveloped within the first stage structure, Rocket Lab was able to lighten its weight. Designed as an expendable upper stage for now, Neutron’s second stage is a six-meter-long carbon fiber composite structure with a single vacuum-optimized Archimedes engine.

Rocket Lab is currently working through a competitive process to select launch site, rocket production facility and Archimedes engine test facility on the U.S. East Coast. Rocket Lab expects to create around 250 new jobs to support the Neutron program with many roles currently open.

Related Content

Pultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Fully U.S.-made fairing launched into space features OOA composites

A United Launch Alliance Atlas V rocket launched a U.S. defense satellite into space. The payload fairing, produced by RUAG Space, is composed of OOA CFRP face sheets.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)