SGL Carbon, Hyundai Motor Group extend partnership for fuel cell components

The extension ramps up current production and delivery volumes of SGL Carbon’s SIGRACET gas diffusion layers for Hyundai fuel cell-powered vehicles.

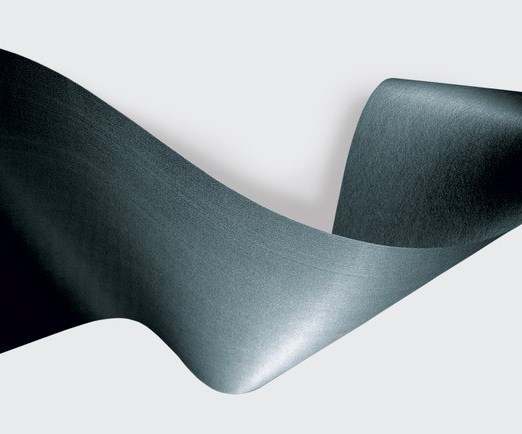

SGL Carbon's SIGRACET gas diffusion layer. Source | SGL Carbon

SGL Carbon (Wiesbaden, Germany) and the Hyundai Motor Group (Seoul, South Korea) announced Dec. 4 that they have extended their supply agreement for production of gas diffusion layers for Hyundai’s NEXO fuel cell cars. The long-term agreement is said to provide for a substantial ramp-up of current production and delivery volumes. However, the investment required to fulfill this contract will not increase the overall capital expenditure budget of SGL Carbon in the next two years, as the company has reprioritized its investment projects.

SGL Carbon plans to more than quintuple its business — from its current business of around 200 customers — with its gas diffusion layer fuel cell components, to annual sales of approximately €100 million (more than $110 million USD). As a result of growing demand, the company says it has gradually stepped up production capacity at its plant in Meitingen, Germany, and is now equipped to manufacture fuel cell components on an industrial scale. In addition, to further advance accelerated commercialization, the gas diffusion layers business will be transferred from the central R&D department Central Innovation (CI) to the business unit Graphite Materials & Systems (GMS) in the fourth quarter of 2019.

SGL Carbon says it has been carrying out research and development into components for fuel cells since the 1990s. The gas diffusion layers regulate the flow of gas within the fuel cell and carry water and heat away and are said to have a significant impact on the power density and efficiency of the fuel cell. SIGRACET gas diffusion layers from SGL Carbon were first used as a standard in the Hyundai iX35 in 2012.

“The extension of the partnership with Hyundai is perfectly aligned to our strategic direction. Intelligent solutions in the area of sustainable energy are one of the key growth drivers for our company,” says Dr. Michael Majerus, spokesman of the board of management of SGL Carbon. “Whether used in a drive system in vehicles or as a stationary power supply, the fuel cell is one of the greenest energy technologies around. The market for fuel cells thus offers enormous potential for us.”

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

-

Recycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)