Teijin Ltd. expands thermoplastic prepreg lineup

CFRTP intermediate materials are now offered with PP, PC and PA matrices, which will now be used as base resins for existing prepreg products.

Photo Credit: Teijin Ltd.

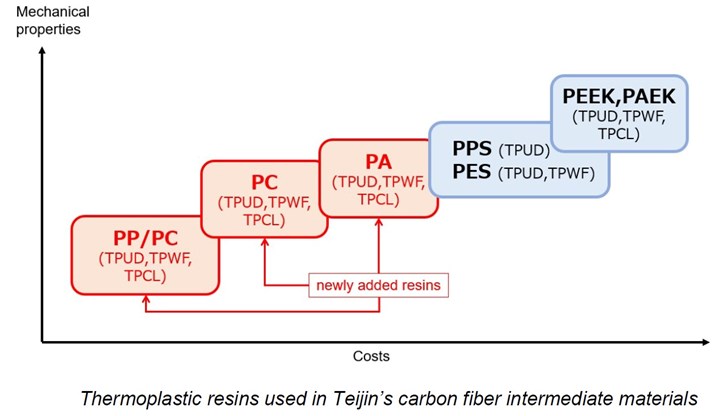

On Feb. 16 Teijin Ltd. (Tokyo, Japan) announced that it has expanded its lineup of carbon fiber thermoplastic intermediate materials with three matrix resins: polypropylene (PP)/polycarbonate (PC) and polyamide (PA). The new resins are now being used as base resins in new versions of the company’s existing prepreg products, including Tenax ThermoPlastic UniDirectional (TPUD), Tenax ThermoPlastic Woven Fabric (TPWF) and Tenax ThermoPlastic Consolidated Laminate (TPCL).

Compared to Teijin’s existing thermoplastic intermediate materials made with polyetheretherketone (PEEK), polyaryletherketone (PAEK), polyphenylene sulfide (PPS) or polyethersulfone (PSE) resins, Teijin says the prepregs made with the three new thermoplastic resins can be molded at lower temperatures for faster and more cost-effective production, making them ideal for applications requiring production efficiency, such as automobiles, sporting goods and precision instruments.

In addition, Teijin is developing new carbon fiber intermediate materials to strengthen its ability to meet diverse customer needs and to continue pursuing its long-term vision for a more sustainable world.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

.jpg;maxWidth=300;quality=90)