Teijin Ltd. joins Spirit AeroSystem Aerospace Innovation Centre

Teijin expects to collaborate with Spirit and other AIC members to enhance innovative technology capabilities, including composites, in the aerospace industry.

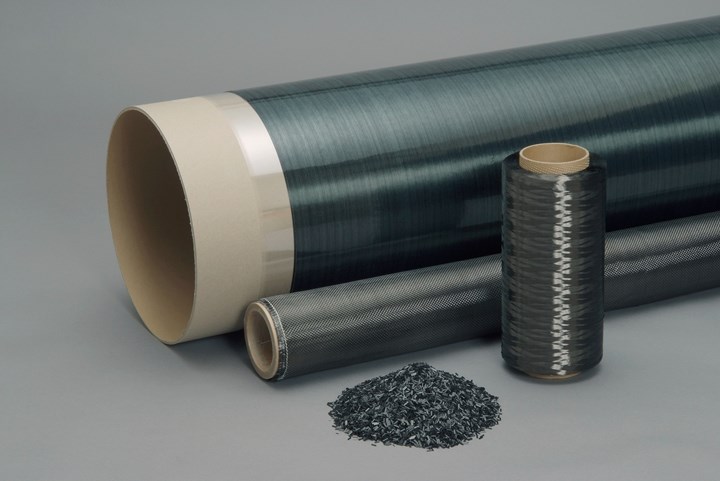

Tenax fiber reinforcement materials. Photo Credit: Teijin Ltd.

Teijin Ltd. (Tokyo, Japan) announced on June 15 that it has joined the Aerospace Innovation Centre (AIC) organized by Spirit AeroSystems Inc. (Wichita, Kan., U.S.), said to be one of the world’s leading manufacturers of aircraft structural components. Teijin will work directly alongside Spirit and other members of the AIC.

The AIC is an 85,000-square-foot center located in Prestwick, Scotland, housing Spirit’s engineering design and manufacturing expertise alongside advanced development and pre-production equipment in a collaborative environment with key partners. Teijin reports that within this space, it will enhance its capabilities to contribute to Spirit AeroSystems’ vision to enable innovative technologies and build a sustainable future. This collaboration will also reportedly strengthen Teijin’s advantage as a leading carbon fibers and composites supplier for aerospace applications.

As one strategic focus of its medium-term management plan for 2020-2022. Teijin notes that it is intensively accelerating its development of mid to downstream applications for aircraft, such as cost-effective carbon fibers with higher-tenacity and higher-tensile modulus, intermediate materials including Tenax dry reinforcement carbon fiber materials (Tenax DR), carbon fiber thermoplastic unidirectional (UD) pre-impregnated tape (Tenax TPUD), carbon fiber thermoplastic consolidated laminate (Tenax TPCL) and thermoset prepreg. Going forward, Teijin intends to further strengthen its carbon fiber and its intermediate material business as a leading solution provider for aircraft applications.

Related Content

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.