Teijin to build advanced fiber-reinforced wood building

New building to incorporate structural timber product comprising a number of layers of dimensioned timber and high-performance fibers bonded with structural adhesives.

Teijin Ltd. (Tokyo, Japan) announced Sept. 25 that it will construct the world’s first building made of advanced fiber-reinforced wood (AFRW), a structural timber product comprising a number of layers of dimensioned timber and high-performance fibers bonded together with structural adhesives. Teijin first developed the materials in 2015, which involved incorporating high-toughness aramid fibers and highly stiff carbon fiber, and hybrid materials incorporating these fibers.

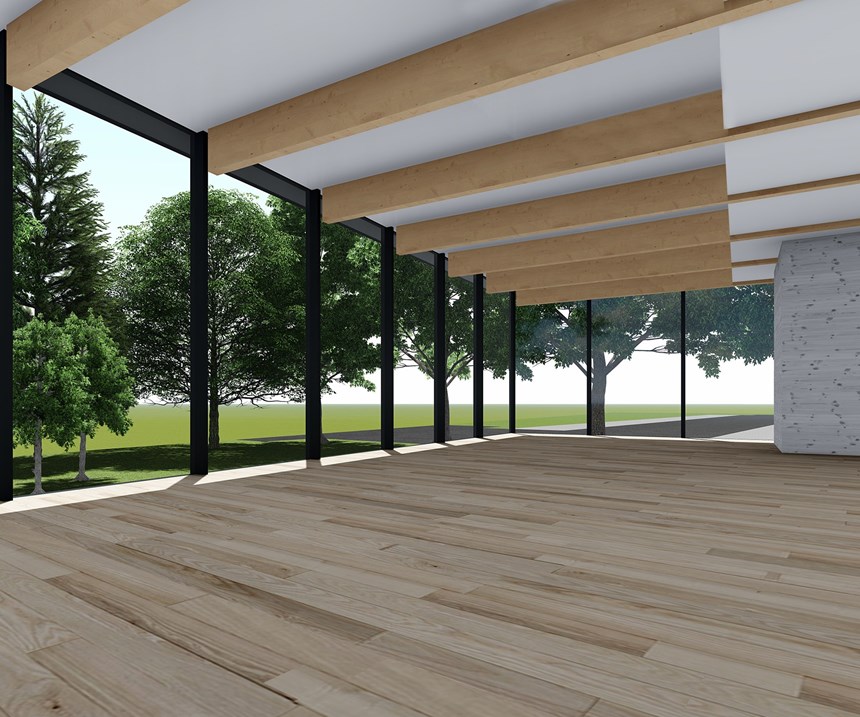

The new building, which will be constructed in Teijin’s Tokyo Research Center in Hino City, exploits the warm texture and unique timber composition of AFRW to help create a stress-free environment. It also aims to realize open and comfortable space by avoiding the use of columns, thus maximizing the inflow of natural light.

The project was approved by Japan’s Ministry of Land, Infrastructure, Transport and Tourism (MLIT, Tokyo Japan) in May and construction will begin in October, with technical support provided by the professional construction firm Maeda Corporation (Tokyo, Japan) and the Structural Engineering Laboratory of Kochi University (Kochi, Japan). Upon completion, Teijin and Maeda will monitor adhesive stability and the vibration durability of AFRW for a period of seven years.

Teijin will continue to develop AFRW technology following construction of this first building and the initial monitoring phase. The aim is to realize safe, comfortable, earthquake-proof wooden buildings as well as the development of sustainable architecture using timber as sustainable resources that absorb CO2. The company expects the new technology and materials to be deployed in general construction by around 2020.

Teijin will also be presenting at Carbon Fiber 2018. Learn more about the event at carbonfiberevent.com.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

.jpg;maxWidth=300;quality=90)