ThermHex receives quality, environmental management certification

Thermoplastic honeycomb core producer earns ISO 9001 and ISO 14001 national and international management system standards.

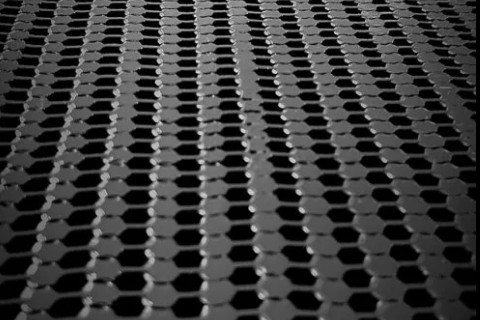

Black honeycomb core. Photo Credit: ThermHex Waben GmbH

ThermHex Waben GmbH (Halle, Germany) has been certified for its quality and environmental management system. The ISO 9001 and ISO 14001 certifications are considered significant national and international standards for management systems. In the combined audit, ThermHex reports that the awareness of environmental relevance and the advantages of its own products over monolithic materials were emphasized.

In addition to evaluating various environmental aspects, the environmental management system also includes monitoring of environmental targets and compliance with environmentally relevant safety standards. Here, it was particularly emphasized that ThermHex makes an additional contribution to CO2 reduction by using green electricity for the already resource-efficient production of its honeycomb cores. In general, all self-imposed quality and environmental targets were exceeded in the past fiscal year, ThermHex notes.

With the certificates for quality and environmental management systems, ThermHex says it underlines its own demands on product and service quality and environmental protection. As a management tool, the certification processes are additionally intended to ensure continued steady improvement in environmental performance and quality, and thus overall company development.

Jochen Pflug, managing director of ThermHex, emphasizes that despite various bottlenecks and the effects of the pandemic, thanks to the company’s employees, both standards were nevertheless successfully met.

ThermHex produces thermoplastic honeycomb cores made of polypropylene (PP) for manufacturers of lightweight sandwich elements. Read, “ThermHex, EconCore invest in automated production for PP honeycomb sandwich, recycled PET products” for more information.

Related Content

-

Recycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

-

Natural fiber composites: Growing to fit sustainability needs

Led by global and industry-wide sustainability goals, commercial interest in flax and hemp fiber-reinforced composites grows into higher-performance, higher-volume applications.

-

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.