Toray to develop sugar from biomass waste for production of resins, fibers

The project aims to use waste from sugarcane agriculture for the production of new bio-based materials.

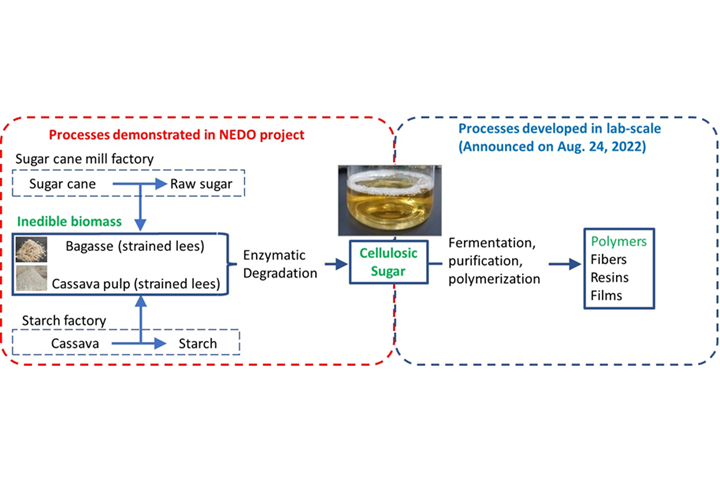

Toray Industries Inc. (Tokyo, Japan) and Mitsui DM Sugar Co. Ltd. are collaborating to manufacture sugars from inedible biomass for the production of fibers, resins and films.

The biomass includes surplus bagasse, a pulpy residue from sugarcane processing, and pulp that results from squeezing cassava at starch factories. Bringing this technology together with another that Toray is developing to create monomers from sugars should contribute to a circular economy, the company says, by making it possible integrate the production of biomass-based polymers for fibers, films, resins and other offerings.

This demonstration project entailed Toray verifying a process to separate, purify, and concentrate cellulose-derived sugars in inedible biomass. It leveraged a membrane-based bioprocess that combines the company’s water treatment membrane technology and enzymes that employ biotechnology. Toray undertook this effort at a demonstration facility in Thailand as part of a project that the New Energy and Industrial Technology Development Organization (NEDO) is supporting. The company proved that carbon dioxide emissions from this process are less than half those of conventional production setups that concentrate sugar solutions by evaporating water.

In 2022, Toray developed a 100% bio-based adipic acid, a raw material for polyamide 66 (nylon 66), from sugars derived from inedible biomass. This achievement came from using a proprietary synthesis technique combining the company’s microbial fermentation technology and chemical purification technology that harnesses separation membranes. The recent demonstration was a first step toward creating a technology to make cellulosic sugar from biomass, putting it on track to mass production. The company now looks to establish an integrated technology to manufacture fiber and resin from abundant agricultural residue, avoiding competition with the food chain.

Toray and Mitsui Sugar Co. Ltd. set up a demonstration plant in January 2017 in Udon Thani Province, Thailand. There, Toray verified and assessed manufacturing process energy savings, production performance, and the economic feasibility of this production system from August 2018 through December 2022. It completed the demonstration in March 2023.

.jpg;width=70;height=70;mode=crop)