Tri-Mack introduces thin, lightweight thermoplastic composite enclosures

Durable, low-cost manufacturing support wide range of industrial uses, with option for embedded EMI shielding.

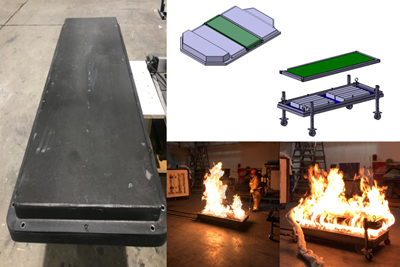

Tri-Mack’s lightweight TPC enclosures can be produced in a range of materials and sizes to best meet end-use requirements. Photo Credit, all images: Tri-Mak Plastics Manufacturing Corp.

Tri-Mack Plastics Manufacturing Corp. (Bristol, R.I., U.S.), a high-performance thermoplastics parts manufacturer announces its latest product development achievement, a lightweight, high-strength enclosure made from just eight plies of unidirectional (UD) carbon fiber-reinforced thermoplastic (CFRTP) tape and only forty thousandths of an inch (0.40-inch) thick.

The new enclosures demonstrate Tri-Mack’s expertise in the production of large, thin covers with deep draws using UD tape. At CAMX, the company is displaying a range of cover sizes and materials made using Tri-Mack’s production process: automated tape laying (ATL), consolidation and stamp forming. Tri-Mack’s thermoplastic composite process produces parts in minutes, rather than the hours typically required for thermosets, the company contends.

Tri-Mack has been developing proprietary methodologies for the automated layup and molding of lightweight thermoplastic composites for more than a decade. “We see these new TPC [thermoplastic composite] covers meeting rising demand for strong, lightweight enclosures that can shield functional components in aircraft, drones and a variety of other industrial uses,” Tom Kneath, vice president for sales and marketing, Tri-Mack Plastics Manufacturing, says. “Where strength and durability are priorities in addition to the lightest weight, continuous fiber TPCs are the material of choice. It is less brittle than thermosets, delivers ten times the strength of injection-molded parts and, with our enclosure, provides a 30% weight reduction versus 6061 aluminum.”

The new enclosures are not limited to carbon fiber. They can be produced using glass fiber, and with different base resins as well, including polyaryletherketone (PAEK), polyetheretherketone (PEEK) and polyetherimide (PEI), providing a variety of customizable properties and solutions.

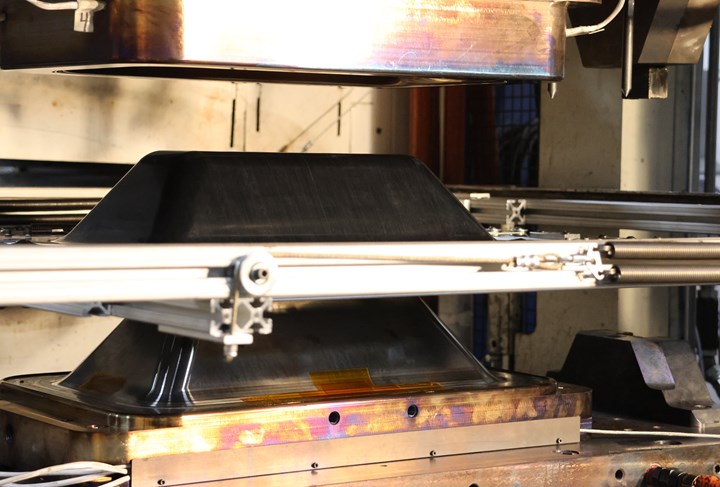

Tri-Mack stamp forms TPC enclosures in minutes using tooling designed and made in-house. Enclosure shown mounted on shuttle after stamp forming in mold.

The enclosure’s manufacturing process also enables added functionality, creating “smart composites” by embedding EMI shielding, or adding localized reinforcement through tailored layups, Tri-Mack notes. “We can add electrically conductive layers into our process to enable EMI shielding performance at a fraction of the weight of metal,” Max McCabe, sales engineer, adds. “This also eliminates the plating and painting process steps of typical EMI solutions used on composite parts.” Electrical conductivity and shielding effectiveness can be tailored to end use using a wide variety of durable composite materials, McCabe notes, further broadening potential applications across aerospace, unmanned air vehicles (UAVs), undersea applications and electric vehicles (EVs).

Tri-Mack’s process engineering manager Ben Lamm, leader of the new enclosure project, says that it was a definite technical challenge to form the large, deep covers out of TPC. “With UD materials you’re stacking plies that are oriented in different directions throughout the part,” he says. “Making complex shapes this way requires individual plies to slip against each other as you are forming. Getting them to move the way you want to produce a consistent, wrinkle-free part requires strategic layup and tool design, as well as subtleties in material handling during processing.”

This level of manufacturing expertise comes naturally to the 48-year-old company. “Tri-Mack has been working in the lightweight composites space for decades and has comprehensive, in-house capabilities,” Kneath says. “We make injection-molded housings that require EMI shielding and thin-wall TPC enclosures that replace metal using assembled pieces and fasteners. Our goal was to build this functionality into a single part and show the industry how lightweighting can improve product performance through fuel efficiency, battery range or increased payload.”

Related Content

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreRead Next

Price, performance, protection: EV battery enclosures, Part 1

Composite technologies are growing in use as suppliers continue efforts to meet more demanding requirements for EV battery enclosures.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)