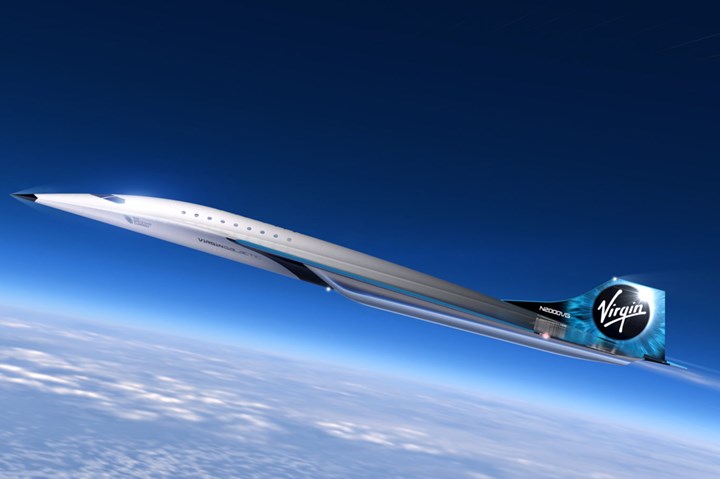

Virgin Galactic completes milestones for Mach 3 aircraft concept

In addition to unveiling the high-speed aircraft design, Virgin Galactic signed an MOU with Rolls-Royce. This follows the company’s completion of its Mission Concept Review and FAA authorization.

Source | Virgin Galactic

Virgin Galactic Holdings Inc., (Mojave, Calif., U.S.) and its and its subsidiary, The Spaceship Co. (TSC; Mojave) announced on August 3 the first stage design scope for the build of its high-speed aircraft design and the signing of a non-binding Memorandum of Understanding (MOU) with Rolls-Royce (London, U.K.) to collaborate in designing and developing engine propulsion technology for high-speed commercial aircraft. This follows the successful completion of its Mission Concept Review (MCR) program milestone and authorization from the Federal Aviation Administration’s (FAA) Center for Emerging Concepts and Innovation to work with Virgin Galactic to outline a certification framework. According to the company, this marks an important step forward in its development of a new generation of high-speed aircraft, in partnership with industry and government leaders, with a focus on customer experience and environmental sustainability.

“We are excited to complete the Mission Concept Review and unveil this initial design aircraft concept, which we envision as blending safe and reliable commercial travel with an unrivaled customer experience,” says George Whitesides, chief space officer, Virgin Galactic. “We are pleased to collaborate with the innovative team at Rolls-Royce as we strive to develop sustainable, cutting-edge propulsion systems for the aircraft, and we are pleased to be working with the FAA to ensure our designs can make a practical impact from the start. We have made great progress so far, and we look forward to opening up a new frontier in high-speed travel.”

Virgin Galactic emphasizes the Mission Concept Review, which included representatives from NASA, as a major program milestone. Its successful completion confirms that the high-speed aircraft’s design concept can meet the high-level requirements and objectives of the mission. Previously, NASA signed a Space Act Agreement with Virgin Galactic to collaborate on high speed technologies.

According to Virgin Galactic, the basic parameters of the initial high-speed aircraft design included a targeted Mach 3-certified delta-wing aircraft that would have the capacity for 9 to 19 people at an altitude above 60,000 feet, and would also be able to incorporate custom cabin layouts to address customer needs, including Business or First Class seating arrangements.

The aircraft design also aims to help head the way toward use of the state-of-the-art sustainable aviation fuel. Virgin Galactic expects baselining these sustainable technologies and techniques into the aircraft design to act as a catalyst for their adoption by the rest of the aviation community.

The MRC concluded that the team can progress to the next phase of design, consisting of defining specific system architectures and configurations, and determining which materials to use in the design and manufacturing of the aircraft. Virgin Galactic’s team will also work to address key challenges in thermal management, maintenance, noise, emissions and economics that routine high-speed commercial flights would entail.

The company emphasizes that the design philosophy of the aircraft is essentially geared around making high-speed travel practical, sustainable, safe and reliable, while making customer experience a top priority. Virgin Galactic says the aircraft is being designed for a range of operational scenarios, including service for passengers on long-distance commercial aviation routes. The aircraft would take off and land like any other passenger aircraft and be expected to integrate into existing airport infrastructure and international airspace around the world.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreRead Next

Virgin Galactic, NASA sign space agreement

The Space Act Agreement (SAA) represents a partnership between Virgin Galactic and NASA for the development of high-speed, and environmentally sustainable, aviation technology.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More