Virginia Tech researchers develop IGA for more efficient modeling of skin-stringer composites with complex cutouts

Isogeometric analysis offers higher rates of convergence and accuracy versus standard FE methods, will be offered as opensource code on GitHub.

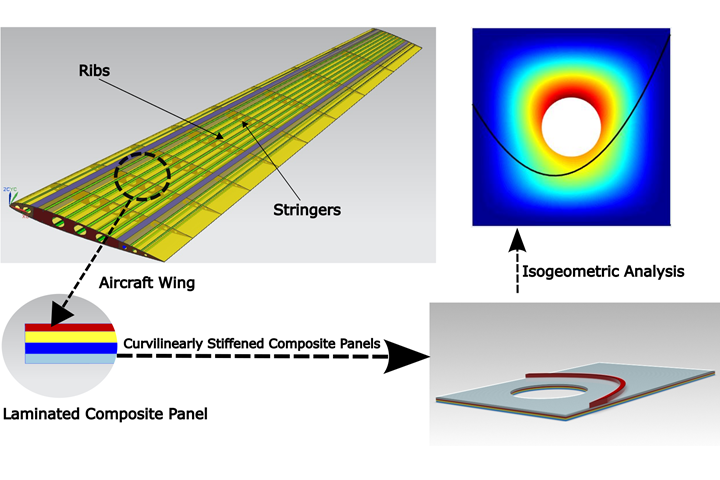

Photo Credit: Balakrishnan Devarajan

Unitized structures are being used to construct lighter and more environment-friendly aircraft. Such advanced, multi-layered composite materials offer high strength-to-weight ratios and thus, are being increasingly used in aerospace and shipbuilding industries amongst others.

However, when used in hypersonic space vehicles, such structures experience significant temperature rise in a short time, resulting from the aerodynamic heating due to friction between the vehicle surface and the atmosphere. Such phenomena are more prominent during reentry and launch processes. For this reason, considering the thermal effects is important in the design and analysis of such structures.

Due to an increase in the requirements placed upon laminated composites, for a plethora of engineering applications, the use of plates with arbitrarily shaped cutouts are unavoidable. But the response of structures to loads can be significantly affected due to the presence of such cutouts. Since the study of laminated composites with cutouts is a complex problem, numerical methods are used extensively. Now, researchers at the Virginia Polytechnic Institute and State University (Virginia Tech, Blacksburg, Va., U.S.) have combined the recently evolved isogeometric analysis (IGA) to model curvilinearly stiffened composite panels with cutouts of various shapes and sizes.

According to Dr. Balakrishnan Devarajan, a former Ph.D student with the Unitized structures Group at Virginia Tech, “IGA offers increased accuracy and efficiency and represents the exact geometry of the stiffeners at each level of mesh refinement. It also enables more flexibility in refinement near the areas where the stiffeners and composite plate are connected.”

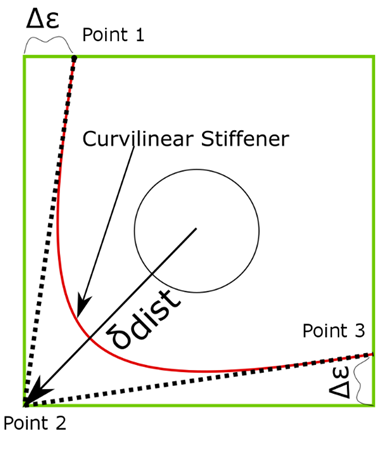

Fig. 1. Parametrization of curvilinear stiffener using three NURBS control points. Photo Credit: Balakrishnan Devarajan

Development completed by Dr. Devarajan and his collaborator, Dr. Rakesh Kapania, introduces a novel way of achieving displacement continuity between the control points of the stiffener and the plate using an interpolation function matrix. The curvilinear stiffener was accurately generated by only three control points (Fig. 1). The researchers used multiple patches to create complex cutout geometries, and also formulated a methodology to enforce interface conditions that preserved the higher-order continuity across multiple patches. The developed method obviates the necessity of having the stiffener nodes be coincident with the nodes of the plate.

Analysis and comparison with standard finite element methods show higher rates of convergence, accuracy and efficiency using IGA. This work will soon be available as an opensource code on GitHub. The research has been published in the Composite Structures article: “Thermal buckling of curvilinearly stiffened laminated composite plates with cutouts using isogeometric analysis”.

Related Content

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

-

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.